Electrical connections – Sterling QVSB User Manual

Page 9

9

2. Hot areas - Areas where the sun's rays, radiation, or

warm air currents may affect control operation.

3. Dead areas - Areas where air cannot circulate freely,

such as behind doors or in corners.

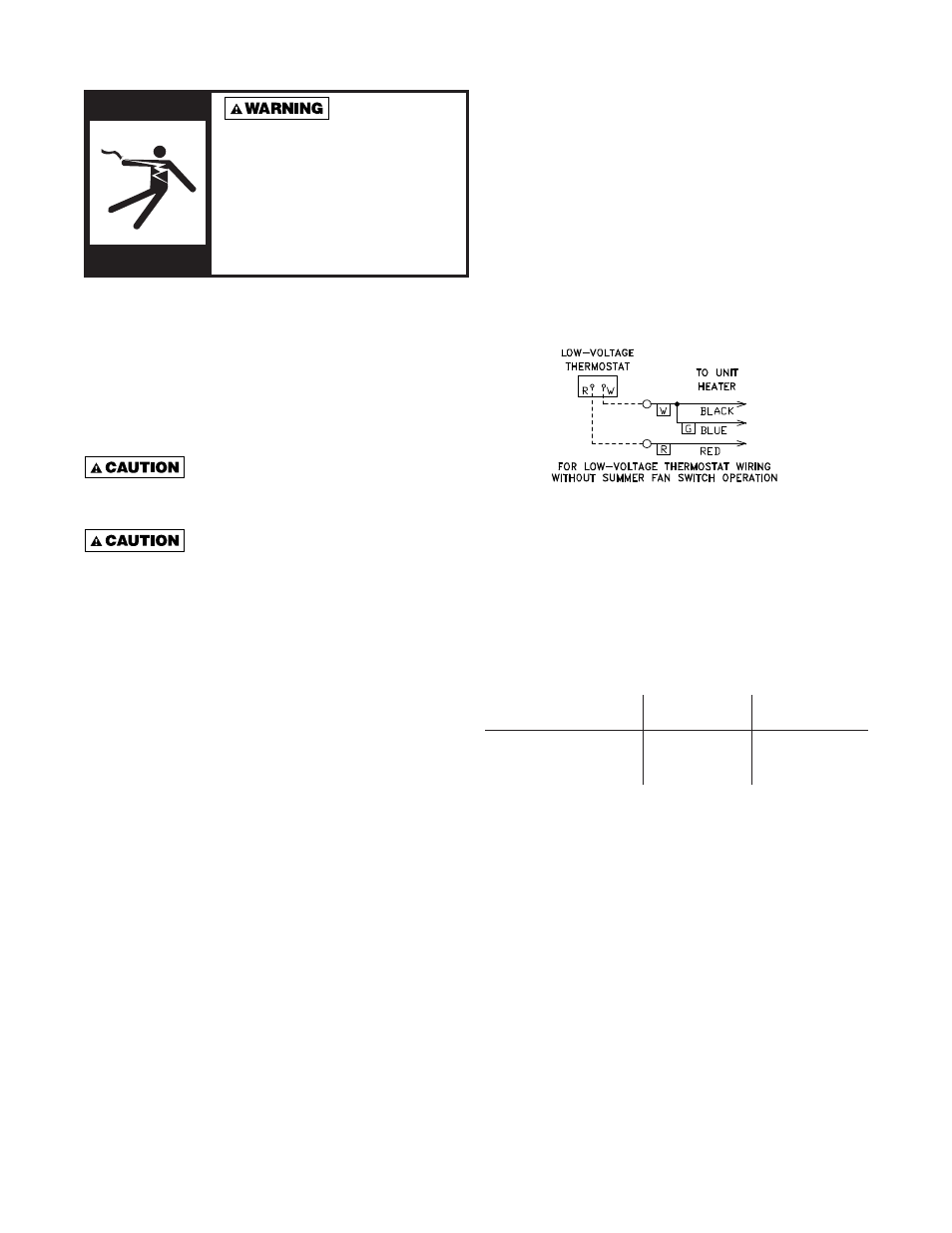

* Ther mostat wires tagged “W” and “G” must be

connected together except when using a general

purpose "SPDT" 24VAC relay and a standard thermostat

with subbase, or when using Honeywell T834H or T834N

thermostats. Also refer to Figure 6 for other wiring

connections.

Figure 8 - C1267G

THERMOSTAT HEAT ANTICIPATOR ADJUSTMENTS:

The initial heat anticipator setpoint should equal the

thermostat's current amperage draw when the unit is

fi ring. This setpoint should be measured for the best

results. Use the recommended ranges as a guide. If

further information is needed, consult your thermostat

manufacturer's instructions.

Recommended Heat Anticipator Setting Ranges:

25 ft. (7.6m)

50 ft. (15.2m)

Gas Ignition Type

T'stat Wiring

T'stat Wiring

For Power Vented Units:

0.85 to 0.90 A

0.90 to 1.1 A

Intermittent (Spark)

Max. Setting

on

T'stat

FAN TIME DELAY CONTROL

Leads from time delay controls are factory wired to the

junction box. The fan control is a time delay relay

(approximately 45 seconds ON, 65 seconds OFF). The

fan control is rated at 17 amps.

NOTICE: The start-up fan delay must not exceed 90

seconds from a cold start.

NOTICE: For all wiring connections, refer to the wiring

diagram that your unit is equipped with (either affi xed

to the side jacket or enclosed in your unit's

installation instruction envelope). Should any original

wire supplied with the heater have to be replaced, it

must be replaced with wiring material having a

temperature rating of at least 105°C.

Should any high limit switch wires have to be

replaced, they must be replaced with wiring material

having a temperature rating of 200°C minimum.

ELECTRICAL CONNECTIONS

HAZARDOUS VOLTAGE!

disconnect ALL ELECTRIC

POWER INCLUDING REMOTE

DISCONNECTS BEFORE

SERVICING. Failure to

disconnect power before

servicing can cause severe

personal injury or death.

Standard units are shipped for use on 115 volt, 60 hertz

single phase electric power. The motor nameplate and

electrical rating on the transformer should be checked

before energizing the unit heater electrical system. All

external wiring must conform to the latest edition of

ANSI/NFPA No. 70 National Electrical Code and

applicable local codes; in Canada, to the Canadian

Electrical Code, Part 1 CSA Standard C22.1.

Do not use any tools (i.e. screwdriver,

pliers, etc.) across the terminals to check for power.

Use a voltmeter.

USE COPPER CONDUCTORS ONLY!

UNIT TERMINALS ARE NOT DESIGNED TO ACCEPT

OTHER TYPES OF CONDUCTORS. Failure to do so

may cause damage to the equipment.

It is recommended that the electrical power supply to

each unit heater be provided by a separate, fused and

permanently live electrical circuit. A disconnect switch of

suitable electrical rating for each unit heater should be

located as close to the gas valve and controls as

possible. Each unit heater must be electrically grounded

in accordance with the latest edition of the National

Electric Code, ANSI/NFPA No. 70 or CSA Standard

C22.1. Sample wiring connections are depicted in

Figures 8, 9, & 10.

The transformer supplied with this unit heater is

internally fused. Any overload or short circuit will ruin

the transformer.

THERMOSTAT WIRING AND LOCATION

NOTICE: The thermostat must be mounted on a

vertical vibration-free surface free from air currents

and in accordance with the furnished instructions.

Mount the thermostat approximately 5 feet (1.5 m) above

the fl oor in an area where it will be exposed to a free

circulation of average temperature air. Always refer to

the thermostat instructions as well as our unit wiring

diagram and wire accordingly. Avoid mounting the

thermostat in the following locations:

1. Cold areas - Outside walls or areas where drafts

may affect the operation of the control.