Pipe installation – Sterling QVSB User Manual

Page 8

8

Check all pipe joints for leakage

using a soap solution or other approved method.

Never use an open fl ame or severe personal

injury or death may occur.

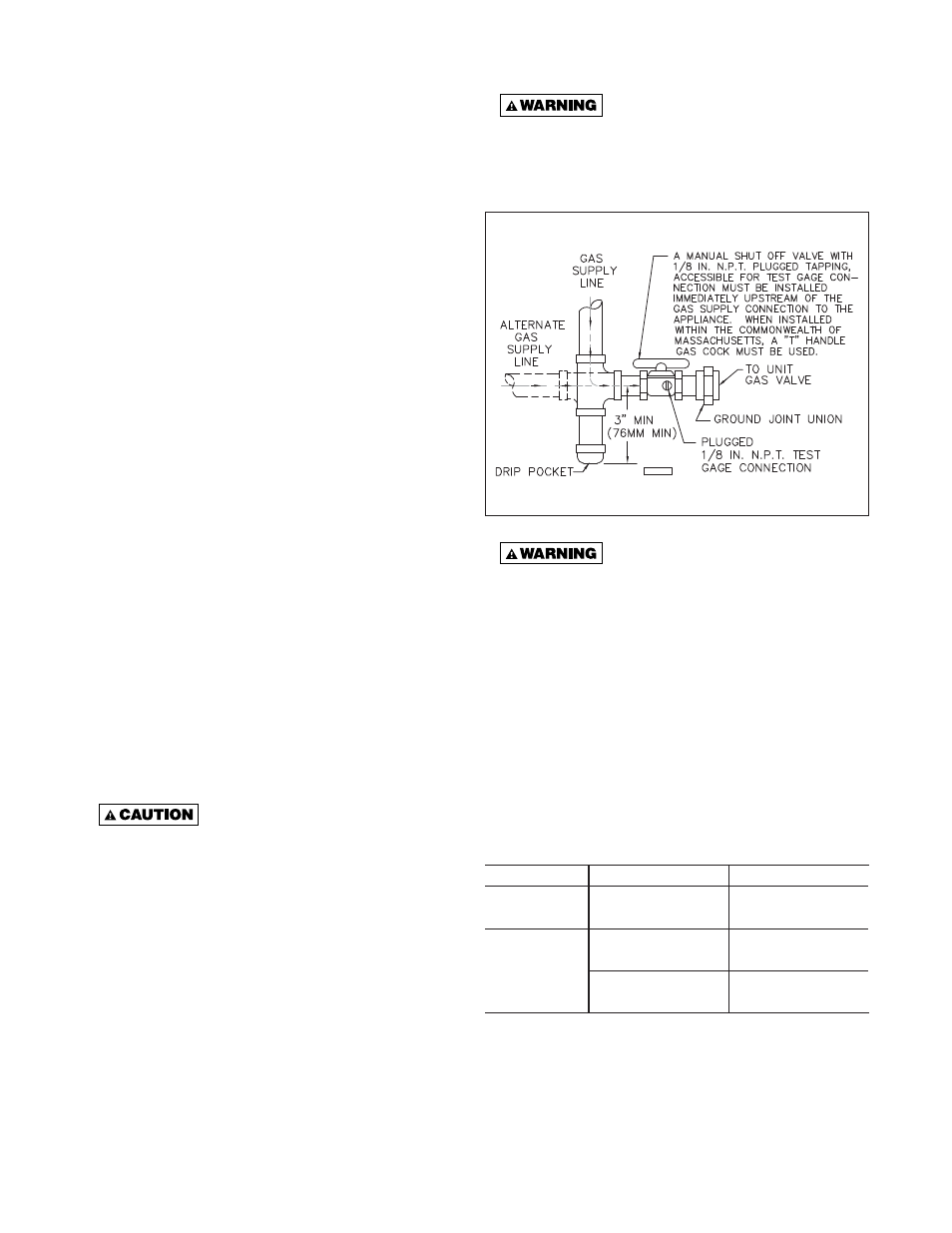

Figure 7 - Pipe Installation, Standard Controls

Never use an open flame to

detect gas leaks. Explosive conditions may

exist which would result in property damage,

personal injury or death.

The appliance and its individual shutoff valve must be

disconnected from the gas supply piping system

during any pressure testing of that system at test pres-

sures in excess of 1/2 psig (3.5 kPa).

The appliance must be isolated from the gas supply

piping system by closing its individual manual shutoff

valve during any pressure testing of the gas supply

piping system at test pressures equal to or less than

1/2 psig (3.5 kPa).

Table 4 - Gas Piping Requirements*

PIPE INSTALLATION

1. Install the gas piping in accordance with

applicable local codes.

2. Check gas supply pressure. Each unit heater must

be connected to a gas supply capable of supplying

its full rated capacity as specifi ed in Table 4. A fi eld

LP tank regulator must be used to limit the supply

pressure to maximum of 14 inch W.C. (3.5 kPa). All

piping should be sized in accordance with the lat-

est edition of ANSI Standard Z223.1 National Fuel

Gas Code; in Canada, according to CSA-B149.

See Tables 1, 3 and 4 for correct gas supply piping

size. If gas pressure is excessive on natural gas

applications, install a pressure regulating valve in

the line upstream from the main shutoff valve.

3. Adequately support the piping to prevent strain on

the gas manifold and controls.

4. To prevent the mixing of moisture with gas, run

the take-off piping from the top, or side, of the

main gas pipe.

5. Optional two-stage units are supplied with a

combination valve which includes:

(a) Manual “A” valve (b) Manual “B” valve

(c) Solenoid valve (d) Pilot safety (e) Pressure

regulator

Pipe directly in to combination valve (see Figure 7).

6. A 1/8 inch N.P.T. plugged tapping, accessible

for test gauge connection, must be installed

immediately upstream of the gas supply connection

to the appliance.

7. Provide a drip leg in the gas piping near the gas

unit heater. A ground joint union and a manual gas

shutoff valve should be installed ahead of the

unit heater controls to per mit ser vicing. The

manual main shutoff valve must be located

external to the jacket. See Figure 7.

8. Make certain that all connections have been

adequately doped and tightened.

Do not overtighten the inlet gas

piping into the valve. This may cause stresses

that would crack the valve!

NOTICE: Use pipe joint sealant resistant to the

action of liquefi ed petroleum gases regardless of

gas conducted.

Gas Type

Manifold

Pressure

Supply Inlet

Pressure

Natural Gas

3.5 in. W.C.

(0.9 kPa)

14 in. W.C. Max.

(3.5 kPa)

5.5 in W.C. Min.

(1.4 kPa)

Propane (LP) Gas

10.5 in. W.C.

(2.6 kPa)

14 in. W.C. Max.

(3.5 kPa)

13.0 in W.C. Min.

(3.2 kPa)

*For single stage applications only, at normal altitudes.

D3631C