Installation – Sterling QVSB User Manual

Page 15

15

INSTALLATION

(continued)

BLOWER SET UP

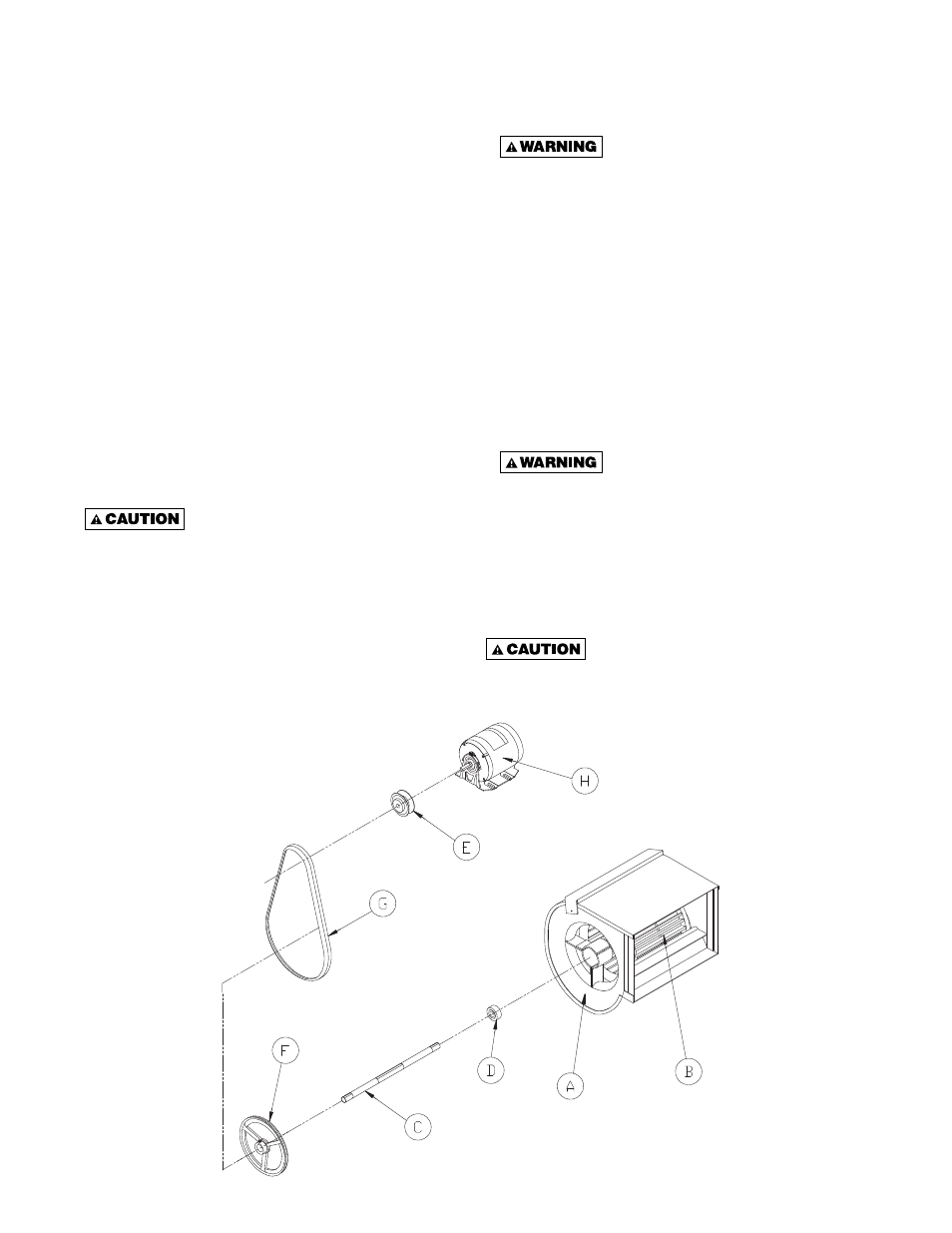

The drive ratio of the motor and blower sheaves has

been preset at the factory for a temperature rise of

65°F at 0 inch W.C. with no external duct work on sys-

tem. If the unit is to be operated under different air fl ow

or pressure requirements, the drive ratio must be altered

by means of the adjustable sheave on the blower motor,

Figure 15.

1. Ensure that all packing material, support blocks,

etc. have been removed from the unit.

2. Adjust the blower drive belt tension by means of

the two tension bolts on the blower motor base.

When proper tension has been achieved, the mid-

point defl ection of the belt will be 3/4 inch when

subjected to a 5 lb force.

3. Recheck all electrical connections.

4. When power is applied, ensure that the motor and

blower are rotating in a clockwise direction when

viewed from the drive side.

5. Measure the current draw of the motor.

The “at speed” current draw of the

motor must never exceed that specifi ed on the motor

rating plate or severe damage to the motor will

result!

BLOWER DRIVE ADJUSTMENT

Never attempt to adjust the drive

belt without fi rst disconnecting all electrical

power to the unit or severe personal injury may

result!

1. Remove the belt guard and loosen the belt tension

bolts on the blower motor base.

2. Loosen the set screw on the adjustable half of the

motor sheave. To increase the blower speed, turn

the adjustable half of the sheave clockwise, counter

clockwise to slow the blower. Retighten the set

screw.

3. Realign the blower and motor sheaves if necessary.

4. Adjust the belt tension as specifi ed in the BLOWER

SET UP section under step 2.

5. Replace the belt guard.

Never operate the unit without

the belt guard in place or severe personal injury

may result!

6. Check that the air fl ow of the unit, the rpm and

current draw of the blower motor and the temperature

rise are within the limits specifi ed in Table 1, the

blower motor rating plate and the rating plate on the

unit, respectively.

Never operate the unit beyond the

specified limits or severe damage to, and or

premature failure of, the unit will result!

NOTE: THE BLOWER ASSEMBLY FOR

THE 100/250 UNITS CONSISTS OF 1 WHEEL,

1 HOUSING, 1 SHAFT AND 1 BEARING SET.

FOR 300/400 UNITS THE BLOWER ASSEMBLY

CONSISTS OF 2 WHEELS, 2 HOUSINGS, 1 SHAFT

AND 1 BEARING SET.

* PART DESCRIPTION

A. Blower Housing

B. Blower Wheel

C. Blower Shaft

D. Bearings

E. Drive Pulley (standard)

F. Driven Pulley (standard)

G. V-Belt

H. Motor

Figure 15 - Motor & Blower Assembly*