Sterling QVSB User Manual

Page 26

26

INSTALLATION INSTRUCTIONS

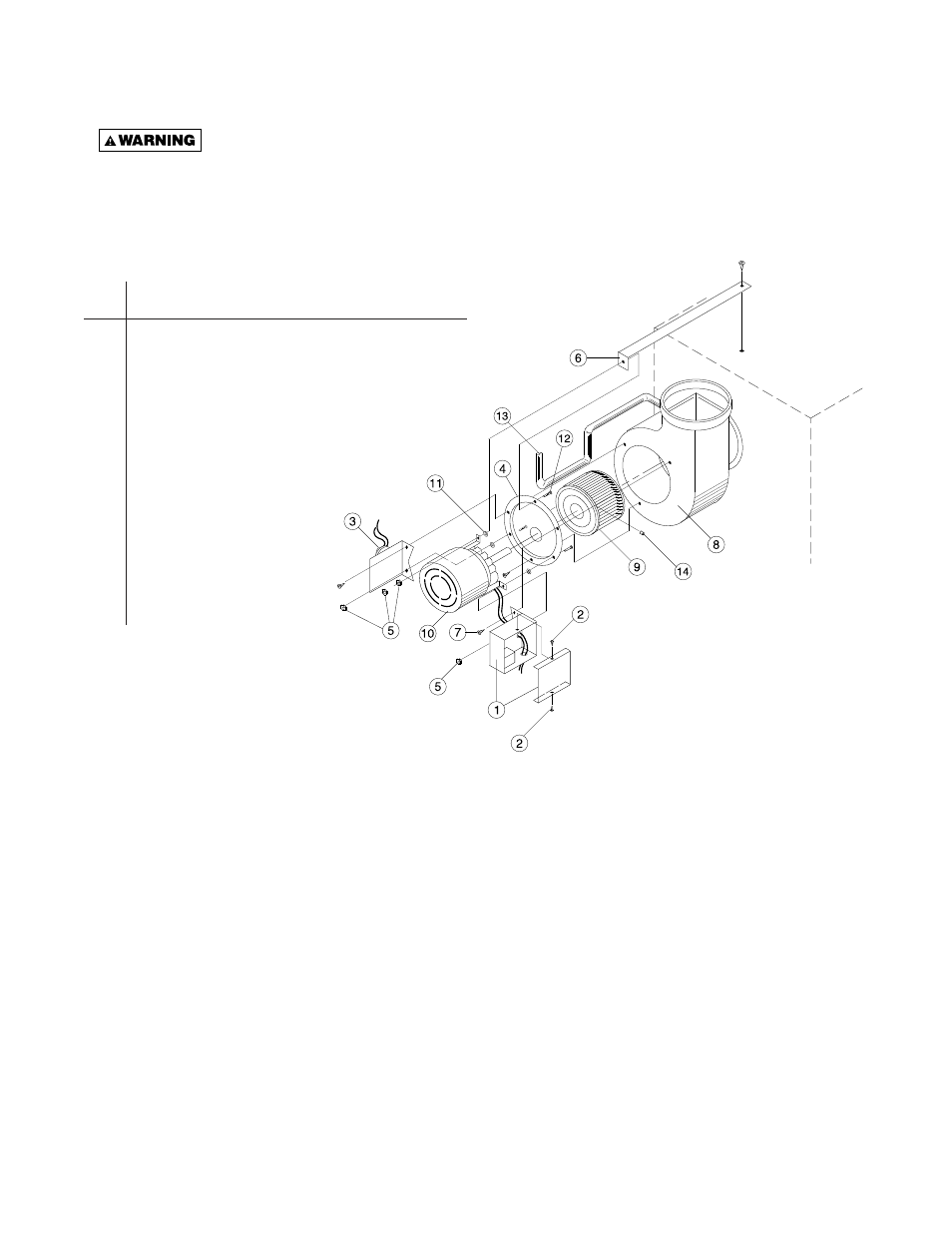

FOR FIELD REPLACEMENT OF POWER VENTER MOTOR

TOOLS AND PARTS NEEDED:

Wire Stripper and Crimper; Slotted Head and #2 Phillips

Head Screwdriver; 3/8" Wrench; 1/8" Allen Wrench (long

handle); marker; (1) 1/4" push on terminal for Wire.

NOTES:

1) Remove the cover from the Relay Junction Box

(Item 1) by removing two screws (Item 2) top and

bottom. Disconnect both wires from the motor lead

ends. One is connected to terminal #4 on the venter

relay, and the other is connected with a wire nut to a

black wire.

2) Remove the sensing tube (Item 3) from the Pressure

Switch/Mounting Bracket (Item 3) at motor end only.

Separated Combustion Units: Remove both tubes at

motor end only - note location.

3) Mark locations of the Relay Junction Box and

Pressure Switching Mounting Brackets along with

the Motor (Item 10) mounts on the Mounting

Adapter Plate (Item 4) - using a marker.

4) Remove nut (Item 5) that secures the Motor Support

Shipping Bracket (Item 6) to the Mounting Adapter

Plate. Pull this bracket away from the Motor

Mounting Adapter Plate.

5) Remove three phillips head screws (Item 7) on the

Motor mounting Adapter Plate. Remove the Motor/

Blower Wheel/Adapter Plate assembly from the

Power Venter Blower Housing (Item 8).

6) Remove the Blower Wheel (Item 9) from the motor

shaft - by removing the set screw (Item 14) using a

1/8" Allen Wrench.

7) Remove the three Motor Mounting Nuts (Item 5),

Space Washers (Item 11), and Screws (Item 12). Do

not lose these parts! Using caution - the motor will

disengage from the Mounting Adapter Plate, along

with the Relay Junction Box and Pressure Switch

Mounting Brackets will also disengage.

8) Reverse order to install the new Power Venter Motor.

9) TEST FIRE THE UNIT FOR A FEW CYCLES,

MAKING SURE THAT THE UNIT IS OPERATING

SATISFACTORY.

Never service any compartment

without fi rst disconnecting all electrical and gas

supplies. Refer to unit’s wiring diagram. This

replacement must be performed only by a

qualifi ed technician.

NOTICE: All hardware (screws, nuts, washers) that

will be removed from the unit will be reused for this

motor replacement. DO NOT LOSE ANY OF THESE

PARTS.

Figure 22 - Identifi cation of Parts

REF.

NO. DESCRIPTION

1

Relay Junction Box/Mounting Bracket Assembly

2

#8 Drill Screws (2 required)

3

Pressure/Mounting Bracket Assembly

4

Mounting Plate Adapter

5

Keps Nut w/External Tooth Lockwasher

(4

required)

6

Motor Support Shipping Bracket

7

Phillips Head Screws (3 required)

8

Power Venter Blower Housing

9

Blower Wheel

10 Motor

11 Space

Washers

(3

required)

12 Machine

Screw

(3

required)

13 Sensing

Tube

14 Set

Screw