Sterling QVSB User Manual

Page 29

29

Digit #1, 2 - Unit Type [UT]

Digit #13 - Motor Type [MT]

B3 - Separated Combustion Blower

1 - Open Drip Proof

2 - Totally Enclosed

Digit #3, 4, 5 - Capacity [CA]

3 - Premium Efficiency, Open Drip Proof

100 - 100,000 BTU/HR

4 - Premium Efficiency, Totally Enclosed

125 - 125,000 BTU/HR

150 - 150,000 BTU/HR

Digit #14 - Blower Motor Sizes [MS]*

175 - 175,000 BTU/HR

A - 1/4 HP w/Contactor

M - 3/4 HP

200 - 200,000 BTU/HR

B - 1/3 HP w/Contactor

N - 1 HP

225 - 225,000 BTU/HR

C - 1/2 HP w/Contactor

P - 1/2 HP w/Magnetic Starter

250 - 250,000 BTU/HR

D - 3/4 HP w/Contactor

R - 3/4 HP w/Magnetic Starter

300 - 300,000 BTU/HR

F - 1 HP w/Contactor

S - 1 HP w/Magnetic Starter

350 - 350,000 BTU/HR

G - 1-1/2 HP w/Contactor

T - 1-1/2 HP w/Magnetic Starter

400 - 400,000 BTU/HR

H - 2 HP w/Contactor

U - 2 HP w/Magnetic Starter

J - 1/4 HP

W - 1/4 HP w/Magnetic Starter

Digit #6 - Furnace Type [FT]

K - 1/3 HP

Y - 1/3 HP w/Magnetic Starter

B - Left Side Access

L - 1/2 HP

*Notes: 1. All 3-phase units [SV = 4, 5, 6, 7] include a contactor as standard.

Digit #7 - Heat Exchanger Construction Material [FM]

2. All single phase units [SV = 1, 2, 3] include a contactor for units equipped with

1 - Aluminized Steel

1-1/2 HP. motor or higher [MS = G, H]

2 - 409 Stainless Steel

3. [MS] options J, K, L, M, N only available with single phase supply voltage [SV = 1, 2, 3].

3 - 321 Stainless Steel

Digit #15 - Accessories [AS]

Digit #8 - Gas Type [GT]

N - Natural Gas

FACTORY INSTALLED

P - Propane Gas (LP)

A8 - Input Derate

S1 - 409 Stainless Steel Burners

K - Natural Gas w/100% Shutoff

S3 - 409 Stainless Steel Flue Collector

M8 - Discharge Duct Flange

Digit #9 - Ignition Control [IC]

2 - Spark Ignition

P4 - Terminal Block Wiring

P6 - Summer/Winter Switch

Digit #10 - Altitude [AL]

A - 0-1,999 ft.

J - 8,000-8,999 ft.

† FIELD INSTALLED (AS-____ )

B - 2,000-2,999 ft.

K - 9,000-9,999 ft.

! Field Installed Accessories are not included in the Unit Number. All Field Installed

C - 3,000-3,999 ft.

L - 10,000-10,999 ft.

Accessories are entered as a separate line item using the catalog number which utilizes

D - 4,000-4,999 ft.

M - 11,000-11,999 ft.

“AS” as a prefix. i.e: A7 becomes AS-A7.

F - 5,000-5,999 ft.

N - Local Gas Supplier Derate

G - 6,000-6,999 ft.

P - Canadian High Altitude 2,000-4,500 ft.

A7 - Pressure Regulator 1/2-2 psi

H5 - Low Ambient Control

H - 7,000-7,999 ft.

F1 - 1-Stage T675A Ductstat

M2-1 - Vent Caps (4") (Unit Capacity 100-175)

Digit #11 - Gas Control [GC]

F2 - 2-Stage T678A Ductstat

M2-2 - Vent Caps (5") (Unit Capacity 200-250)

A - Single Stage

M2-3 - Vent Caps (6") (Unit Capacity 300-400)

B - Two Stage

G1 - 1-Stage T87K Mercury Free Thermostat

M3-1 - Adaptors (5"-4") (Unit Capacity 100-175)

H - Electronic Modulation w/Room Sensing

w/Subbase Kit

M4 - Vertical Concentric Flue Kit

J - Electronic Modulation w/Duct Sensing

G2 - 1-Stage T87K Mercury Free Thermostat

M5 - Horizontal Concentric Flue Kit

K - Electronic Modulation w/Duct Sensing & Room Override Stat

w/TG511A Guard Kit

M7 - 2 to 4 Point Suspension Kit

L - Electronic Modulation w/External 4-20 mA Input

G3 - 1-Stage T834N Mercury Free

N - Electronic Modulation w/External 0-10 VDC Input

Thermostat w/Fan Switch

P5 - 24V SPST Relay-Specify Purpose

G5 - 2-Stage TH5220D Mercury Free

Digit #12 - Supply Voltage [SV]

Thermostat w/Subbase

Q1 - "Y" Splitter Nozzle

1 - 115/1/60

5 - 230/3/60

G6 - Locking Thermostat Cover

Q2 - 30 Degree Nozzle

2 - 208/1/60

6 - 460/3/60

G8 - 1-Stage T6169C Line Voltage Stat

Q3 - 60 Degree Nozzle

3 - 230/1/60

7 - 575/3/60

w/Subbase

Q4 - 90 Degree Nozzle

4 - 208/3/60

Z - Special

G9 - 1-Stage T822K Mercury Free

Q5 - Poly Tube Adaptor (Unit Capacity 150-400)

Note: Supply Voltages [SV] 2-7 include field mounted step down transformer.

Thermostat

Q6 - Vertical Louvers

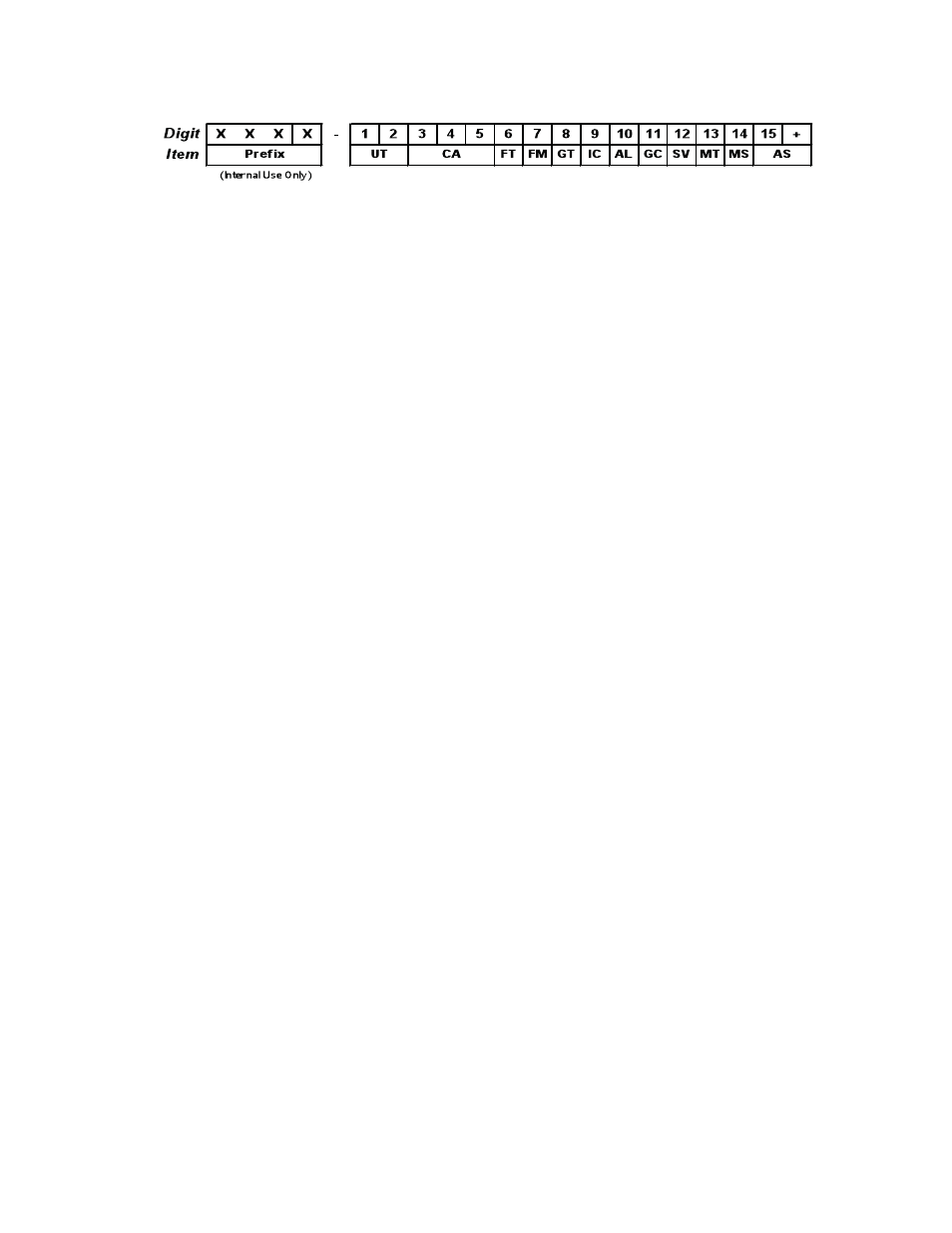

SEPARATED COMBUSTION BLOWER

UNIT NUMBER DESCRIPTION

SEPARATED COMBUSTION BLOWER

UNIT NUMBER DESCRIPTION