Maintenance, 1. overall dissolved-oxygen metering system – Yokogawa DO202 2-Wire Dissolved Oxygen Analyzer User Manual

Page 58

IM 12J05C01-01E

It is important for maintaining the measurement

accuracy of the EXA DO series of wire dissolved-

oxygen metering system to perform inspection and

maintenance at fixed intervals. It also serves to pre-

vent problems from arising.

This chapter describes daily inspection and main-

tenance for the purpose of maintaining system per-

formance.

7-1. Overall dissolved-oxygen metering system

Tables 7-1 and 7-2 show the inspection and main-

tenance items for equipment composing dissolved-

oxygen metering system. The procedure of inspec-

tion and maintenance for the dissolved-oxygen

transmitter is described in Section 7-2. For inspec-

tion and maintenance of the sensors and holders,

see each instruction manual respectively.

7-1-1. Inspection and maintenance to be imple-

mented periodically

Table 7-1. shows the items which are recommended

to be inspected and maintained periodically.

7-1-2. Inspection and maintenance to be imple-

mented on occasion

Occasionally implement the maintenance that is not

directly related to measurement functions and main-

tenance associated with errors.

Maintenance 7-1

7. MAINTENANCE

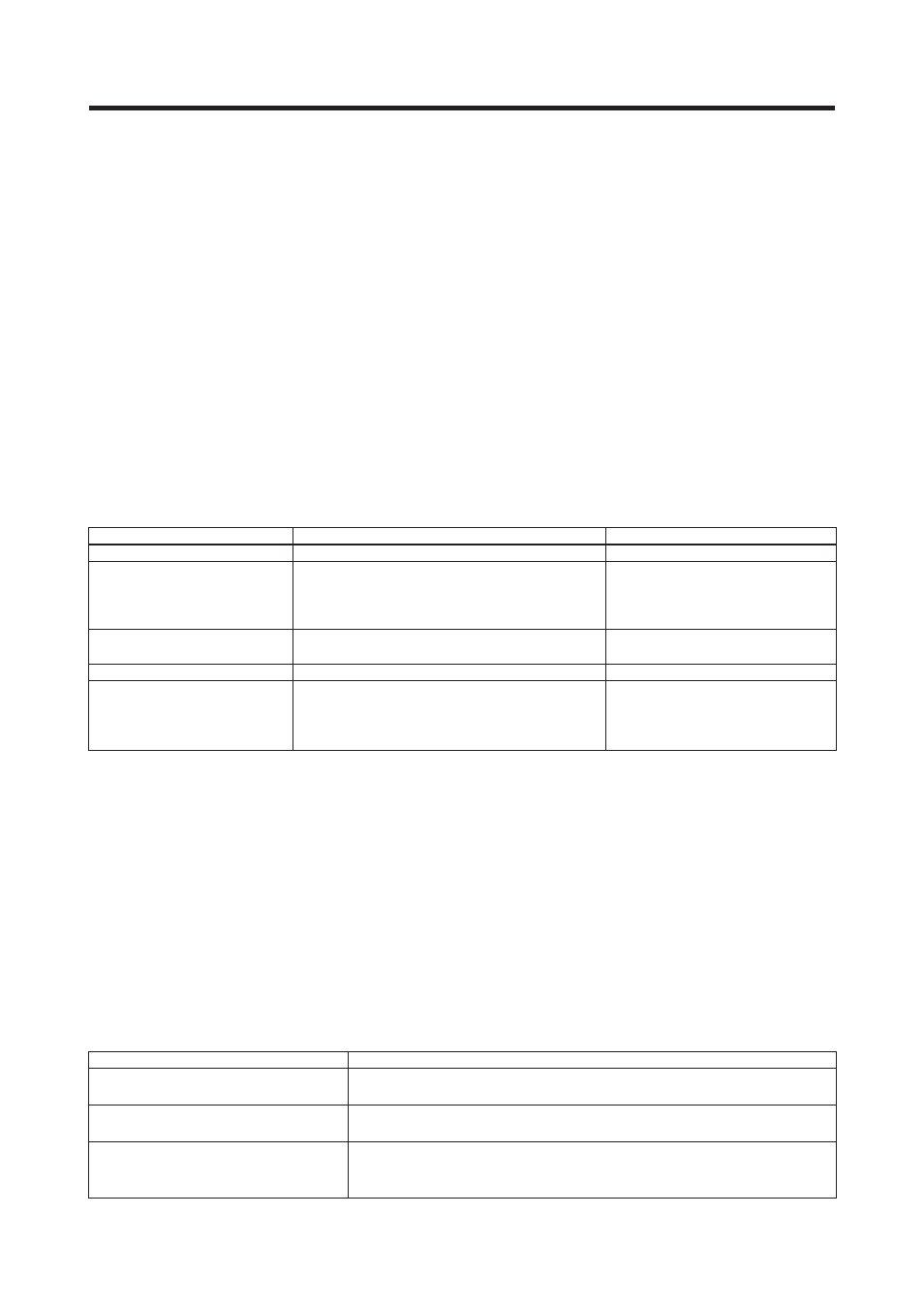

Table 7-1. Items for periodic inspection and maintenance of dissolved-oxygen metering system

Instrument or apparatus

Item

Recommended Interval

All equipment

a. Calibration

a. 1 to 2 months

Dissolved oxygen sensor

a. Cleaning of membrane

a. 1 to 2 months

b.

Polishing of silver electrode

b. 6 to 8 months

surface and replacement of electrolyte

c. Replacement of membrane assembly

c. 6 to 8 months

Dissolved oxygen transmitter

a. Inspection of temperature indication

a. 6 months

(error check)

Float holder

a. Sweeping of winch mechanism

a. (depends on installation environment)

Immersion holder

a. Inspection of sensor holding O-ring

a. 6 months

b. Sweeping of cleaner nozzle

b. 1 to 2 months

c.

Inspection for leakage from the solenoid

c. 6 months

valve for cleaning utility

7-2. Periodic maintenance for the EXA DO202

transmitter

The DO202 transmitter requires very little periodic main-

tenance. The housing is sealed to IP65

(NEMA 4X) standards, and remains closed in normal

operation. Users are required only to make sure the

front window is kept clean in order to permit a clear

view of the display and allow proper operation of the

pushbuttons. If the window becomes soiled, clean it

using a soft damp cloth or soft tissue. To deal with more

stubborn stains, a neutral detergent may be used.

Note:

Never used harsh chemicals or solvents. In

the event that the window becomes heavily

stained or scratched, refer to the parts list

(Chapter 9) for replacement part numbers.

When you must open the front cover and/or glands,

make sure that the seals are clean and correctly fit-

ted when the unit is reassembled in order to maintain

the housing’s weatherproof integrity against water and

water vapor. The DO measurement uses small signal

currents and may otherwise be prone to problems

caused by exposure of the circuitry to condensation.

Table 7-2. Items for occasional inspection and maintenance of dissolved-oxygen metering

Faulty phenomenon

System content of inspection

Error E2 occurrence

Check whether the dissolved oxygen sensor membrane is contaminated or not.

Check whether the nozzle is clogged or not.

Error E3 occurrence

Polish the silver electrode surface of the dissolved oxygen sensor and replace the

electrolyte.

It is difficult to see the inside of the transmitter Wipe off the dirt on the transparent window using tissue paper or

through the window

the like. (Use detergent for hard-to-clean dirt.)