Yokogawa EJA530E User Manual

Page 49

<9. General Specifications>

9-9

IM 01C25F01-01E

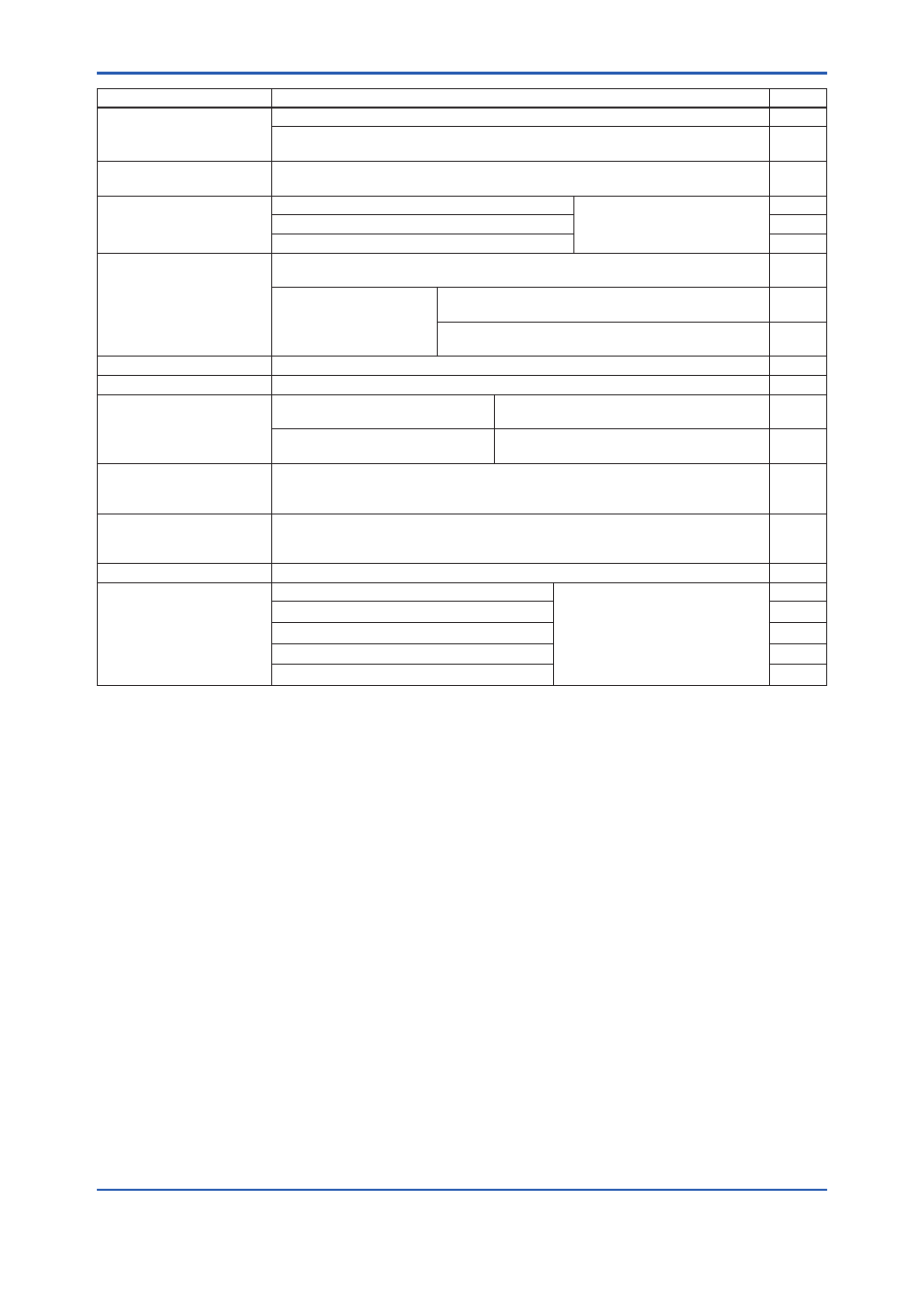

Item

Description

Code

Oil-prohibited use

Degrease cleansing treatment.

K1

Degrease cleansing treatment with fluorinated oilfilled capsule.

Operating temperature –20 to 80°C( –4 to 176°F)

K2

Capsule fill fluid

Fluorinated oil filled in capsule

Operating temperature –20 to 80°C( –4 to 176°F)

K3

Calibration units *

6

P calibration (psi unit)

(See Table for Span and

Range Limits.)

D1

bar calibration (bar unit)

D3

M calibration (kgf/cm

2

unit)

D4

Output limits and failure

operation *

7

Failure alarm down-scale: Output status at CPU failure and hardware error is

–5%, 3.2 mA DC or less.

C1

NAMUR NE43 Compliant

Output signal limits:

3.8 mA to 20.5 mA

Failure alarm down-scale: Output status at CPU

failure and hardware error is –5%, 3.2 mA DC or less.

C2

Failure alarm up-scale: Output status at CPU

failure and hardware error is 110%, 21.6 mA or more.

C3

Gold-plated diaphragm *

15

Surface of isolating diaphragm is gold plated, effective for hydrogen permeation.

A1

Wired tag plate

304 SST tag plate wired onto transmitter

N4

Data configuration at

factory *

8

Data configuration for HART

communication type

Software damping, Descriptor, Message

CA

Data configuration for BRAIN

communication type

Software damping

CB

Advanced diagnostics *

16

Multi-sensing process monitoring

• Impulse line blockage detection *

17

• Heat trace monitoring

DG6

European Pressure

Equipment Directive *

18

PED 97/23/EC

Category: III, Module: H, Type of Equipment; Pressure Accessory-Vessel,

Type of Fluid; Liquid and gas, Group of Fluid: 1 and 2

PE3

Material Certificate

*9

Process connector

M15

Pressure test/

Leak test certificate

Test Pressure: 200 kPa (2 kgf/cm

2

) *

10

Nitrogen(N

2

) Gas or Water *

14

Retention time: one minute

T05

Test Pressure: 2 MPa (20 kgf/cm

2

) *

11

T06

Test Pressure: 10 MPa (100 kgf/cm

2

) *

12

T07

Test Pressure: 50 MPa (500 kgf/cm

2

) *

13

T08

Test Pressure: 70 MPa (10150 psi) *

20

T15

Contact Yokogawa representative for the codes indicated as ‘-’.

*1:

Applicable for Electrical connection code 2, 4, 7, and 9.

*2:

Not applicable for option code /AL.

*3:

Not applicable with color change option.

*4:

This specification is included when amplifier case code 2 is specified.

*5:

Check/External indicator terminals cannot be used when this option code is specified. Not applicable for output signal code F.

*6:

The unit of MWP (Max. working pressure) on the name plate of a housing is the same unit as specified by option codes D1, D3, and

D4.

*7:

Applicable for output signal codes D, E and J. The hardware error indicates faulty amplifier or capsule.

*8:

Also see ‘Ordering Information’.

*9:

Material traceability certification, per EN 10204 3.1B.

*10: Applicable for capsule code A.

*11: Applicable for capsule code B.

*12: Applicable for capsule code C.

*13: Applicable for capsule code D of EJ510 and EJ530.

*14: Pure nitrogen gas or pure water is used for oil-prohibited use (option codes K1 and K2).

*15: Applicable for wetted parts material code S.

*16: Applicable only for output signal code -E and -J.

*17: The change of pressure fluctuation is monitored and then detects the impulse line blockage. See TI 01C25A31-01E for detailed

technical information required for using this function.

*18: Applicable for measurement span code D. If compliance with category III is needed, specify this option code.

*19: Applicable for EJX630A, EJA510E and EJA530E.

Not applicable for the combination of measurement span code A and wetted parts material code H.

Not applicable for option code K2, K3 or A1.

When specified range value includes minus value for A capsule, the accuracy shall be the standard accuracy even if high accuracy

option (/HAC) is specified.

*20: Applicable for capsule code D of EJX610A and EJX630A.