4 disassembly and reassembly, 1 replacing the integral indicator, Disassembly and reassembly -3 8.4.1 – Yokogawa EJA530E User Manual

Page 35: Replacing the integral indicator -3, Caution

<8. Maintenance>

8-3

IM 01C25F01-01E

8.4 Disassembly and

Reassembly

This section describes procedures for disassembly

and reassembly for maintenance and component

replacement.

Always turn OFF power and shut off and release

pressures before disassembly. Use proper tools for

all operations. Table 8.2 shows the tools required.

Table 8.2

Tools for Disassembly and Reassembly

Tool

Quantity

Remarks

Phillips

screwdriver

1

JIS B4633, No. 2

Slotted

screwdriver

1

Allen wrenches

3

JIS B4648

One each, nominal 3, 4 and

2.5 mm Allen wrenches

Wrench

1

Width across flats, 17 mm

Torque wrench

1

Adjustable

wrench

1

Socket wrench

1

Width across flats, 16 mm

Socket driver

1

Width across flats, 5.5 mm

Tweezers

1

CAUTION

Precautions for ATEX Flameproof Type

Transmitters

• Flameproof type transmitters must be, as

a rule, removed to a non-hazardous area

for maintenance and be disassembled and

reassembled to the original state.

• On the flameproof type transmitters the two

covers are locked, each by an Allen head bolt

(shrouding bolt). When a shrouding bolt is

driven clockwise by an Allen wrench, it is going

in and cover lock is released, and then the

cover can be opened.

When a cover is closed it should be locked

by a shrouding bolt without fail. Tighten the

shrouding bolt to a torque of 0.7 N·m.

Shrouding Bolt

Shrouding Bolt

F0802.ai

Figure 8.2

Shrouding Bolts

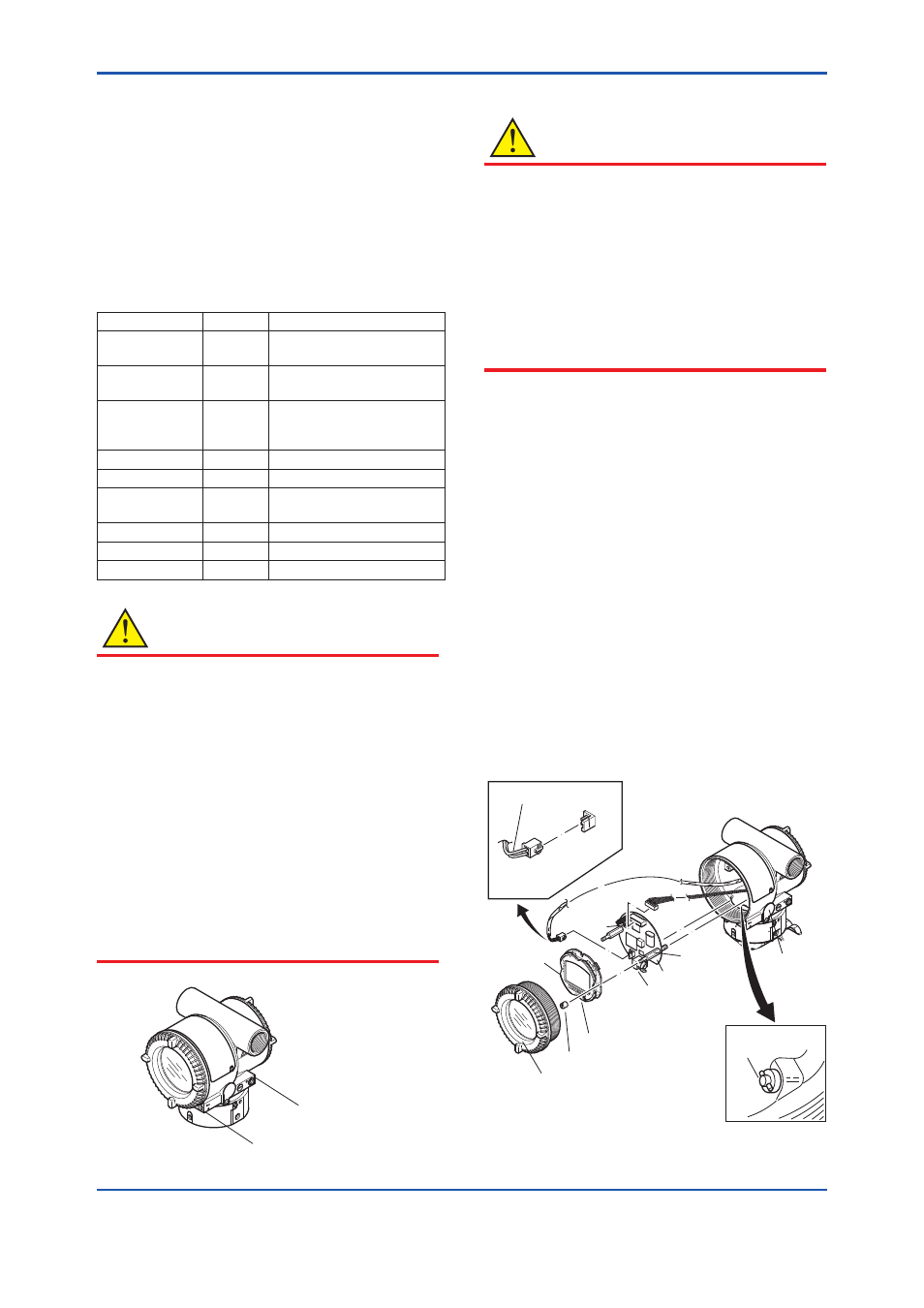

8.4.1 Replacing the Integral Indicator

CAUTION

Cautions for Flameproof Type Transmitters

Users are prohibited by law from modifying the

construction of a flameproof type transmitter.

This would invalidate the agency approval for the

use of the transmitter in a rated area.

It follows that the user is prohibited from using

a flameproof type transmitter with its integral

indicator removed, or from adding an integral

indicator to a transmitter. If such modification is

absolutely required, contact Yokogawa.

This subsection describes the procedure for

replacing an integral indicator. (See figure 8.3)

■ Removing the Integral Indicator

1) Remove the cover.

2) While supporting the integral indicator with one

hand, loosen its two mounting screws.

3) Dismount the LCD board assembly from the

CPU assembly.

When doing this, carefully pull the LCD board

assembly straight forward so as not to damage

the connector pins between it and the CPU

assembly.

■ Attaching the Integral Indicator

1) Align both the LCD board assembly and CPU

assembly connectors and engage them.

2) Insert and tighten the two mounting screws.

3) Replace the cover.

F0803.ai

Press

forward

Output terminal cable

Zero-adjustment

screw pin

Slide

switch

Boss

Zero-

adjustment

screw

Integral

indicator

Mounting screw

Amplifier Cover

CPU assembly

Bracket

(for zero-adjustment

screw pin)

LCD board assembly

Figure 8.3

Removing and Attaching LCD Board

Assembly and CPU Assembly