2 zero point adjustment, Zero point adjustment -2, Important – Yokogawa EJA530E User Manual

Page 30

<7. Operation>

7-2

IM 01C25F01-01E

Using the integral indicator

• If the wiring system is faulty, the display stays

blank.

• If the transmitter is faulty, an error code is

displayed.

Self-diagnostic error on the integral indicator

(Faulty transmitter)

F0703.ai

Figure 7.3

Integral Indicator with Error Code

NOTE

If any of the above errors are indicated on

the display of the integral indicator or the

communicator, refer to subsection 8.5.3 for the

corrective action.

■ Verify and Change Transmitter Parameter

Setting and Values

The parameters related to the following items are

set at factory as specified in order.

• Calibration range

• Integral indicator display

• Software damping (optional)

Other parameters like following are shipped with the

default setting.

• Low-cut

• Process alarm setting

• Signal characterizer

• Write protection

To confirm or change the values, see IM 01C25T01-

06EN or 01C25T03-01E.

7.2 Zero Point Adjustment

After completing preparations for operating the

transmitter, adjust the zero point.

Zero point adjustment can be done by turning the

transmitter’s zero-adjustment screw or by using

the communicator. This section describes the

procedure for the zero-adjustment screw. For the

communicator procedure, see the communication

manual.

IMPORTANT

Do not turn off the power to the transmitter

immediately after performing a zero point

adjustment. Powering off within 30 seconds of

performing this procedure will return the zero

point to its previous setting.

NOTE

Before performing this adjustment, make sure

that the external zero adjustment function has

NOT been disabled by a parameter setting.

To check the output signal, use a digital multimeter,

calibrator, or communicator.

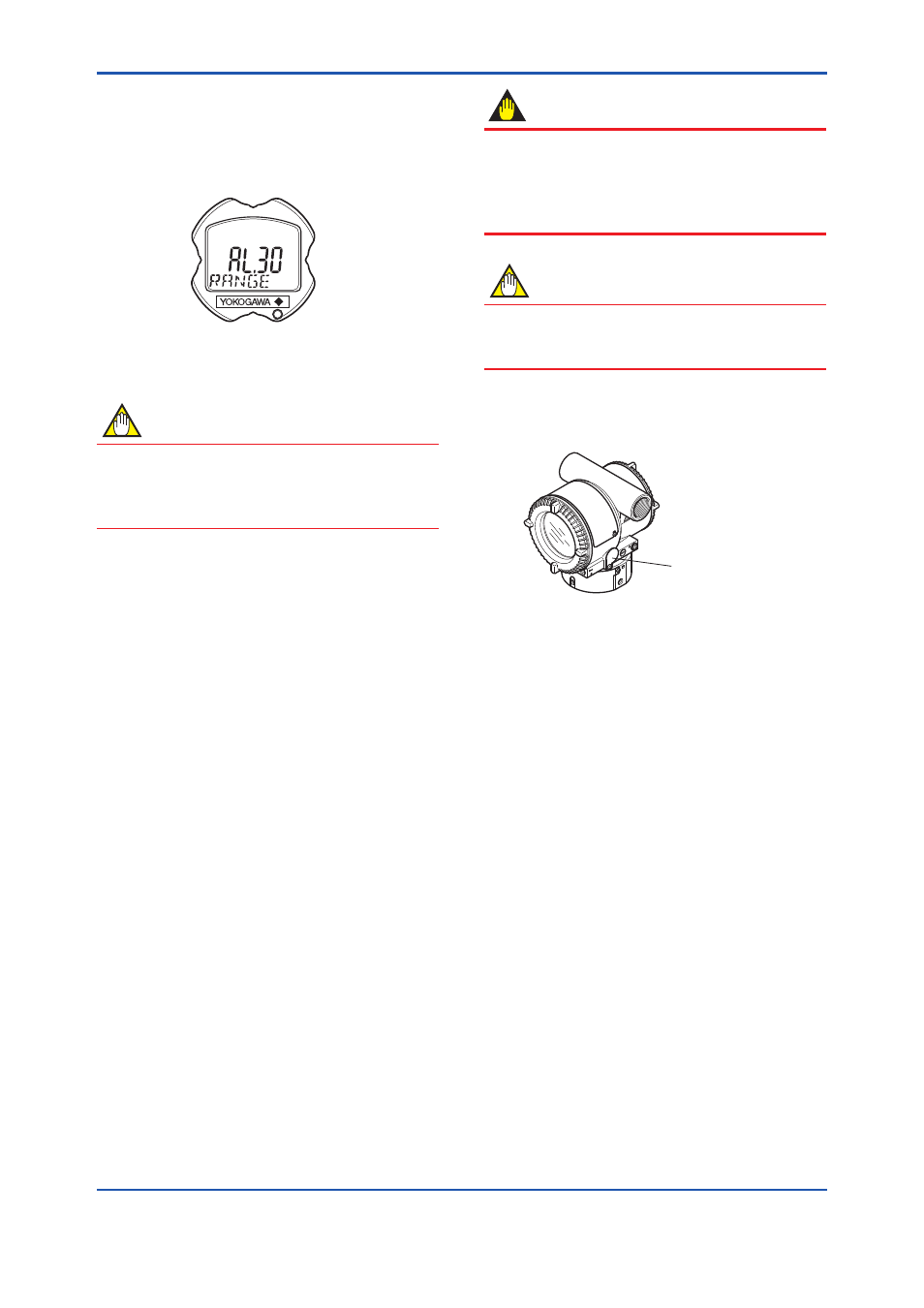

Zero-adjustment

screw cover

F0704.ai

Figure 7.4

External Zero-adjustment Screw

The zero-adjustment screw is located inside the

cover.

(1) When you can obtain the Low Range Value

from the actual measured value of 0% (0

kPa, atmospheric pressure);

For pressure measurement using gauge pressure

transmitters, follow the steps below before

performing zero point adjustment.

1) Close the tap valve (main valve).

2) Loosen the fill plug so that the pressure applied

to the transmitter is only the head of the seal

liquid.

3) Adjust the zero point at this status.

4) After the adjustment, close the fill plug and then

gradually open the tap valve.