Operating instructions – SaltDogg 92426SSA Under Tailgate Spreader User Manual

Page 5

5

TM

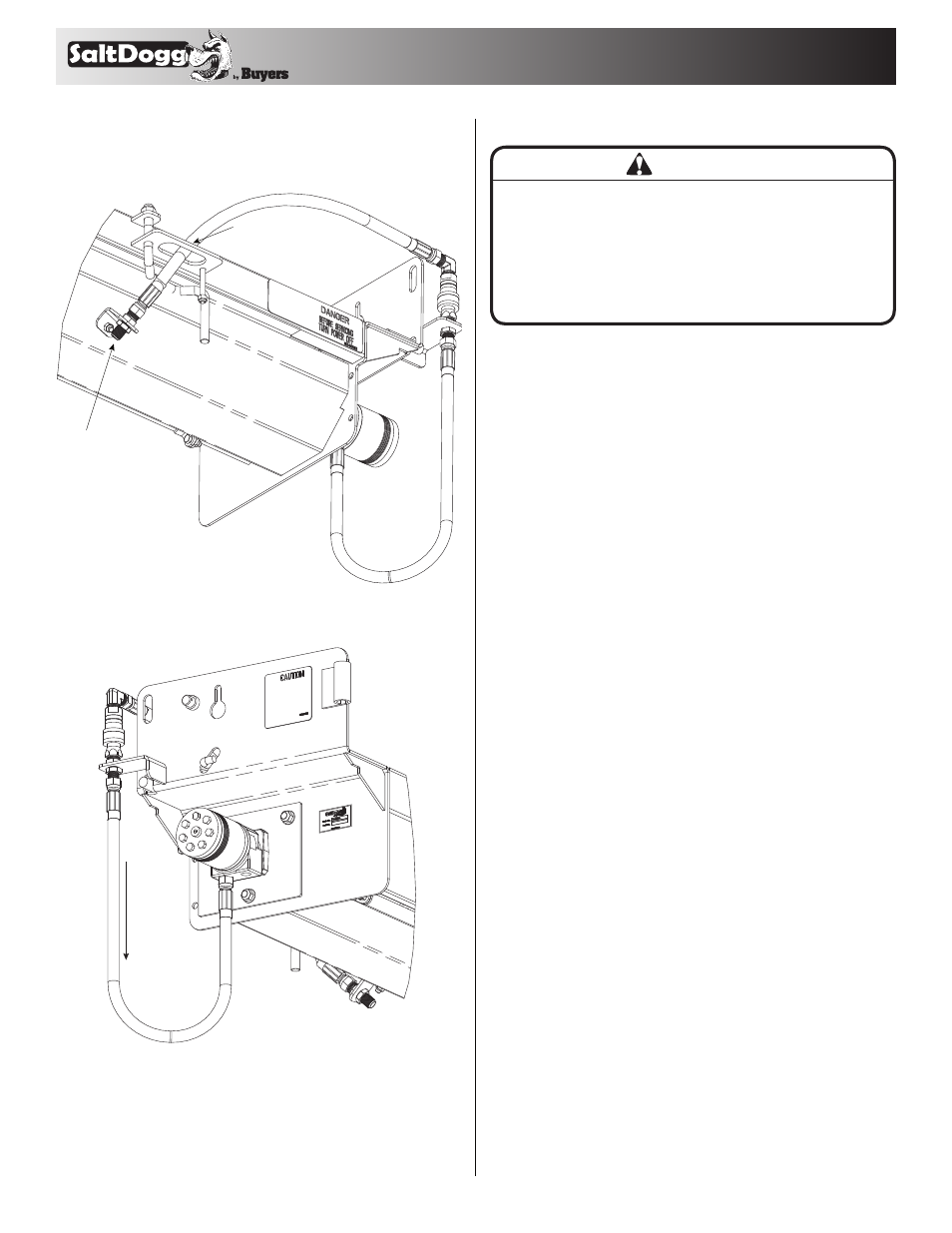

Auger Quick Disconnect Installation

Operating Instructions

1. Pre-start up.

A. Use high grade non foaming hydraulic oil to fill

reservoir about 3/4 full.

B. Position valve on/off lever to off.

C. Move auger and spinner knobs on the valve to

the open position.

D. Engage PTO and circulate hydraulic oil for sev-

eral minutes to warm up.

E. Move valve on/off lever to on.

F. Inspect hydraulic system for leaks.

G. Check auger and spinner to see if they are work-

ing properly.

H. Refill reservoir to 3/4 full.

I. Hydraulic system should now be ready for use.

2. Initial use of spreader

A. Shut off spinner and auger knobs and position

the on/off lever to on. Engage the PTO and allow

the hydraulic system to warm up.

B. Open the cover plate and secure vertically with

locking brackets.

C. Open dump body tailgate as wide as possible

from bottom without bearing against cover plate.

Set stop chains.

D. Position spinner assembly to the far left (drivers

side), tighten clamp. Determine placement of mate-

rial at various spinner and auger speeds by spread-

ing a small amount of material (Far left position

used to spread (3) three or (4) four lane highway

from right lane).

E. Position spinner assembly to the far right (pas-

senger side), tighten clamp. Determine placement

of material at various spinner and auger speeds

by spreading a small amount of material (Far right

position used to spread (4) four lane highway from

left lane).

F. Changing auger and spinner speeds on the valve

and placing spinner at various positions from left to

right will produce various spread patterns.

CAUTION

A. Be sure everyone is standing clear.

B. Be alert for anything that may require shutting

down the system.

C. Before working in or around spreader equip-

ment, be sure all hydraulic controls are moved to

off position.

Attach Inlet

Flow Here

Hose must pass

through bracket

Flow to

Motor