Installation instructions - hydraulic models, Spreader operation - hydraulic models, Main components hydraulic plumbing diagram – SaltDogg 1400550SS / -H Self-Contained Hopper Spreader User Manual

Page 6

6

amount of material going into the spinner.

• Decreasing the engine RPM will decrease

the speed of the conveyor and therefore

amount of material going into the spinner.

• Opening or closing the feed gate door will

determine the amount of material dropping

onto the spinner for any conveyor speed.

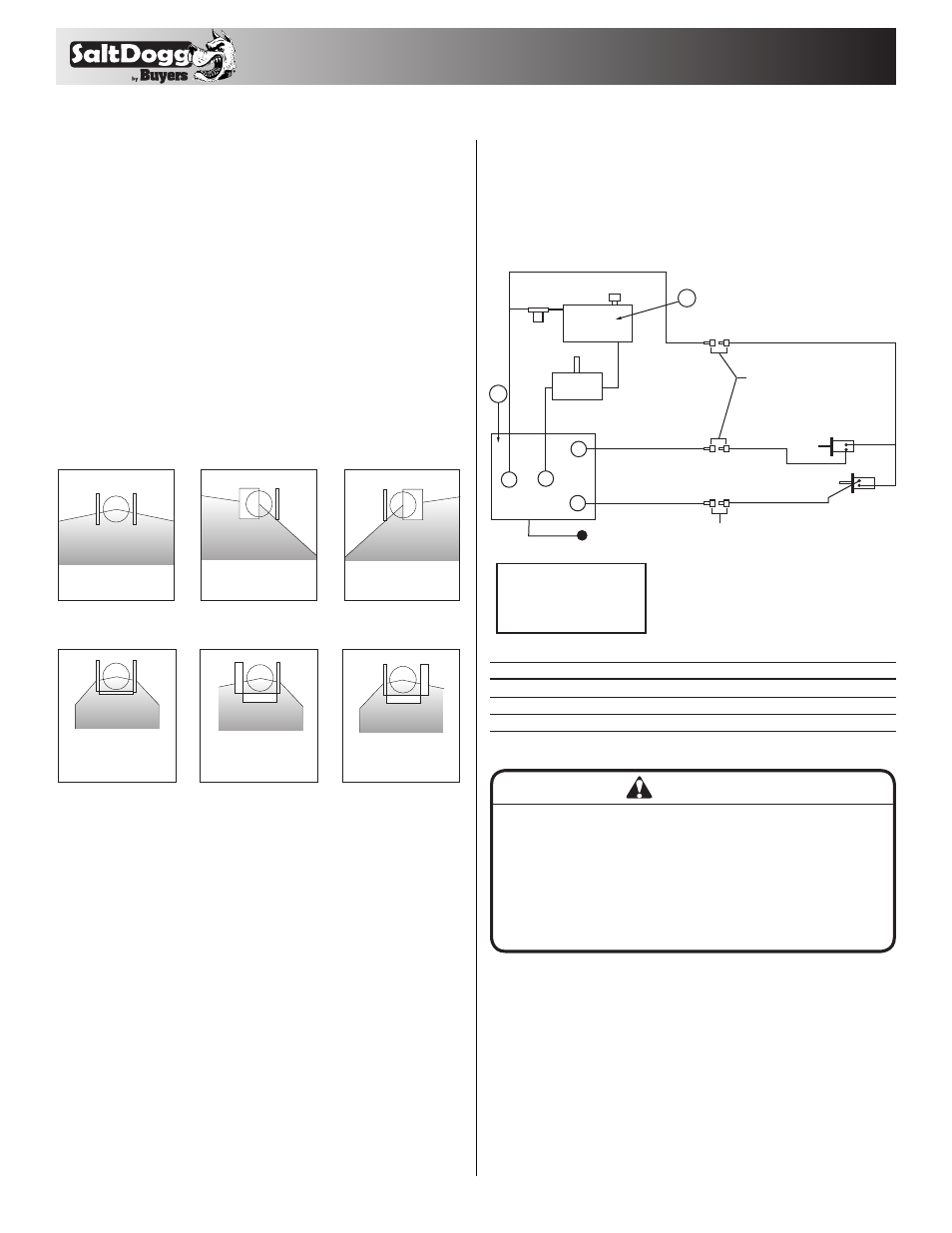

Below are illustrations that show the baffles effect on

the spread pattern as viewed from the top of the spin-

ner disk.

Installation Instructions - Hydraulic Models

1. During assembly take precautions to keep all hy-

draulic components as clean as possible.

2. Allow enough hose length to prevent kinking and

stretching of the hoses and to permit raising the dump

body. Support long hoses with wire ties or clamps.

3. Protect hoses from wear caused by sliding and/or

vibration.

4. For proper rotation of conveyor chain and spinner

motors, hoses may be reversed. The spinner rotates

clockwise when looking down from the top.

Note: Use of a pipe joint sealant compatible with

hydraulic oil is recommended for all screw fittings.

5. Use swivel type hose ends to connect hoses to

flow valve. Damage to valve body may occur if the

fittings in flow valve are over tightened.

6. A 10 micron return line filter is recommended to

protect the pump, valve, and motors from wear caus-

ing contamination.

1

HV715

1

Dual Flow Regulator Valve

2

–

1

Reservoir 25 Gal Min

N/S

HVC1

1

Dual Flow Regulator Console

ITEM

PART NO.

QTY.

DESCRIPTION

Main Components

Hydraulic Plumbing Diagram

ON/OFF Lever

1/2" Quick Disconnects

3/4" (1)

Wire Hose

3/4" (1) Wire Hose

1/2" (1) Wire Hose

1/2" (1) Wire Hose

1/2" (1) Wire Hose

Conveyer

Chain Motor

Spinner Motor

3/4" Quick

Disconnects

3/4" (2) Wire Hose

1-1/4" Spiral

Suction Hose

10 Mircon

Filter

3/4" (2) Wire Hose

1/2" (1) Wire Hose

Tank

Pump

Valve

2

T

A

P

S

Valve Key

T= Tank/Reservoir

P= Pump/Pressure In

A= Auger (Conveyer Chain)

S= Spinner

(1) Single braid wire hose

(2) Double braid wire hose

1

Spreader Operation - Hydraulic Models

Initial Priming and Inspecting of the System

1. Use high grade non-foaming hydraulic oil to fill res-

ervoir about 3/4 full.

2. Position valve on/off lever to off.

CAUTION

• Be sure everyone is standing clear of spreader.

• Be alert for anything that may require shutting

down the system.

• Before working in or around spreader equipment,

be sure all hydraulic controls are moved to off

position.

3. Move auger (conveyor chain) and spinner knobs on

the valve to the open position.

4. Engage PTO and circulate hydraulic oil for several

minutes to warm up.

5. Move valve on/off lever to on.

6. Inspect hydraulic system for leaks.

7. Check conveyor chain and spinner to see if they

are working properly and rotating the correct direc-

tion. To reverse rotation, switch the hydraulic lines at

the motor.

Both internal

baffles out

Left baffle in,

Right baffle out

Right baffle in,

Left baffle out

All baffles adjusted

down for a confined

spread pattern

Right baffle deflects

material down;

heavy on right side

Left baffle deflects

material down;

heavy on left side

Internal Baffle Adjustment

External Baffle Adjustment