Winch angle mounting, Cable installation / tensioner operation, Hydraulic system requirements – Ramsey Winch RPH-25000 (JERR-DAN) User Manual

Page 4

WINCH ANGLE MOUNTING

Use (8) 5/8" diameter grade 5 or better bolts to attach mounting angles to the wrecker.

CABLE INSTALLATION / TENSIONER OPERATION

CAUTION: THE CABLE TENSIONER IS NOT INTENDED TO BE ENERGIZED ON A BARE DRUM. Before

applying air to the cable tensioner, engage the clutch and run the winch in the reel in direction winding one

full wrap of cable on the drum. This prevents damage to the cable tensioner.

1.

Unwind cable by rolling it out along the ground to prevent kinking. Securely wrap end of wire rope,

opposite hook, with plastic or similar tape to prevent fraying.

CAUTION: WINCH IS DESIGNED FOR UNDERWIND CABLE USE ONLY.

2.

Insert the end of cable, opposite hook end, under drum barrel and into the cable anchor hole in drum

barrel. Secure cable to drum barrel, using set screw furnished with winch. TIGHTEN SETSCREW

SECURELY.

3.

Engage the clutch and carefully run the winch in the "reel-in" direction. Keeping tension on end of

cable, spool about five wraps of cable onto the drum and stop. Using a hammer, tap these five

wraps tightly over against the cable anchor flange side of the cable drum. Finish winding all the

cable onto the cable drum. As cable winds onto the drum, watch the tensioner. Tensioner must be

free to move without obstruction to function properly. If tensioner touches any surrounding struc-

ture, correct the problem.

Adjust the free-spool effort of the cable tensioner. Disengage the winch clutch and free spool some

cable off the drum. Adjust the air pressure to the cable tensioner to achieve the desired free spool

effort that also prevents "bird nesting" of the cable.

CAUTION: DO NOT EXCEED 80 PSI AIR PRESSURE TO THE AIR TENSIONER ACTUATORS.

Once you have adjusted the air pressure to the desired level, only minor adjustment may be required if

your pressure regulator setting drifts.

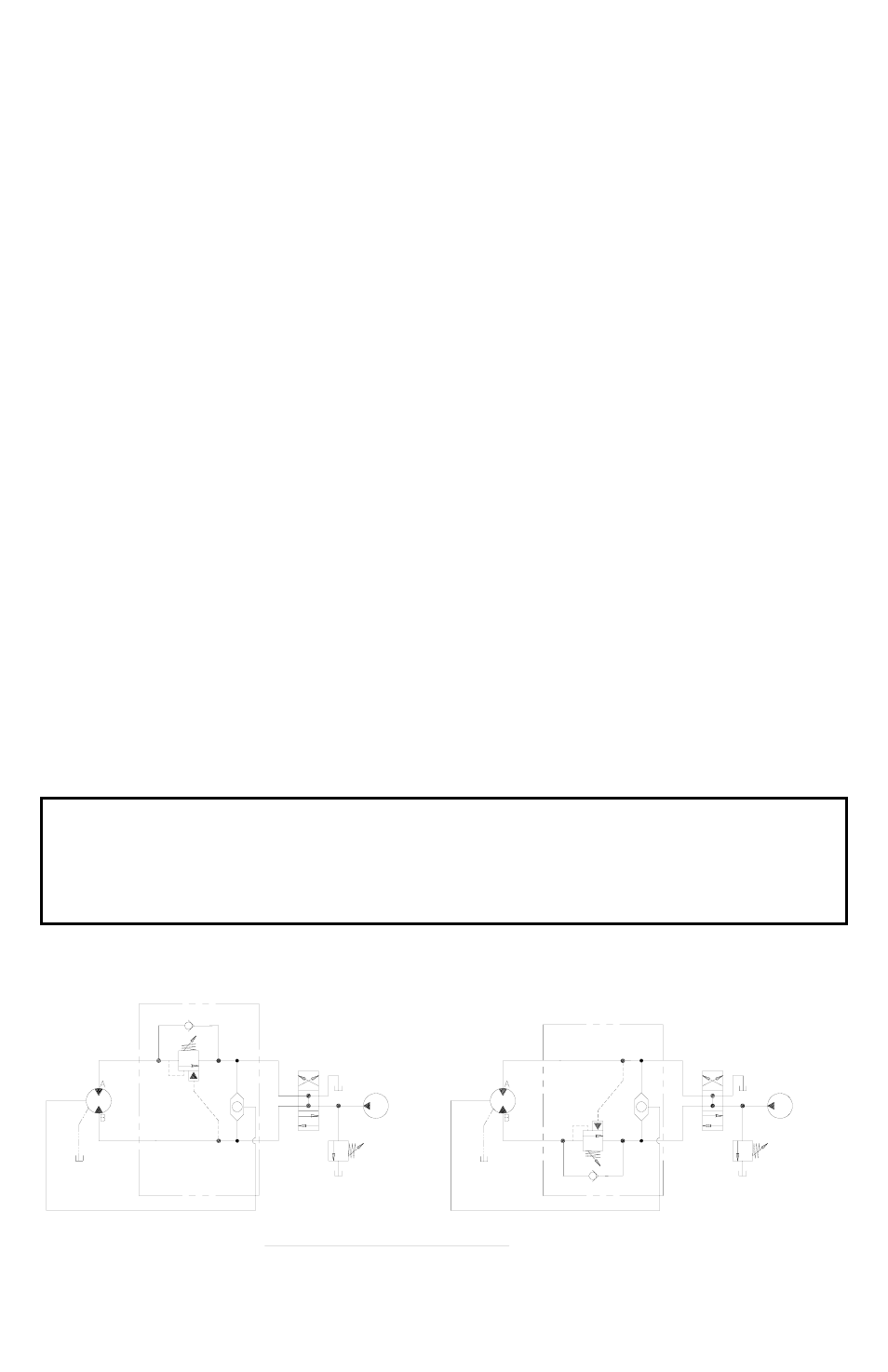

HYDRAULIC SYSTEM REQUIREMENTS

OPTIONAL

EXTERNAL

CASE DRAIN

LINE

OPTIONAL

EXTERNAL

CASE DRAIN

LINE

BRAKE

PORT

MOTOR

3 POSITION

4 WAY VALVE

(MOTOR SPOOL)

B PORT

MOTOR CONTROL VALVE

WITH BRAKE RELEASE

PUMP

SYSTEM

RELIEF

MOTOR

BRAKE

PORT

SYSTEM

RELIEF

MAX FLOW &

PRESSURE AT

RATED LOAD

15 GPM

3000 PSI

PUMP

3 POSITION

4 WAY VALVE

(MOTOR SPOOL)

A PORT

MOTOR CONTROL VALVE

WITH BRAKE RELEASE

TYPICAL HYDRAULIC SYSTEM SCHEMATIC

MAX FLOW &

PRESSURE AT

RATED LOAD

15 GPM

2500 PSI

CAUTION: SYSTEM BACK PRESSURE MUST NOT EXCEED 50 PSI OR BRAKE SHAFT SEAL FAILURE

CAN OCCUR. IF BACK PRESSURE EXCEEDS 50 PSI, AND CANNOT BE REDUCED, AN EXTERNAL CASE

DRAIN LINE SHOULD BE RUN FROM THE MOTOR CASE DRAIN PORT (SEE PAGES 15-16) TO TANK OR

A LINE/CONNECTION THAT HAS A PRESSURE BELOW 50 PSI. THE DRAIN LINE MUST BE ROUTED SO

THAT SOMEWHERE ALONG ITS PATH, THE LINE IS HIGHER THAN THE MOTOR SHAFT CENTERLINE.

2