Oil fill hole – Ramsey Winch RPH-25000 (JERR-DAN) User Manual

Page 15

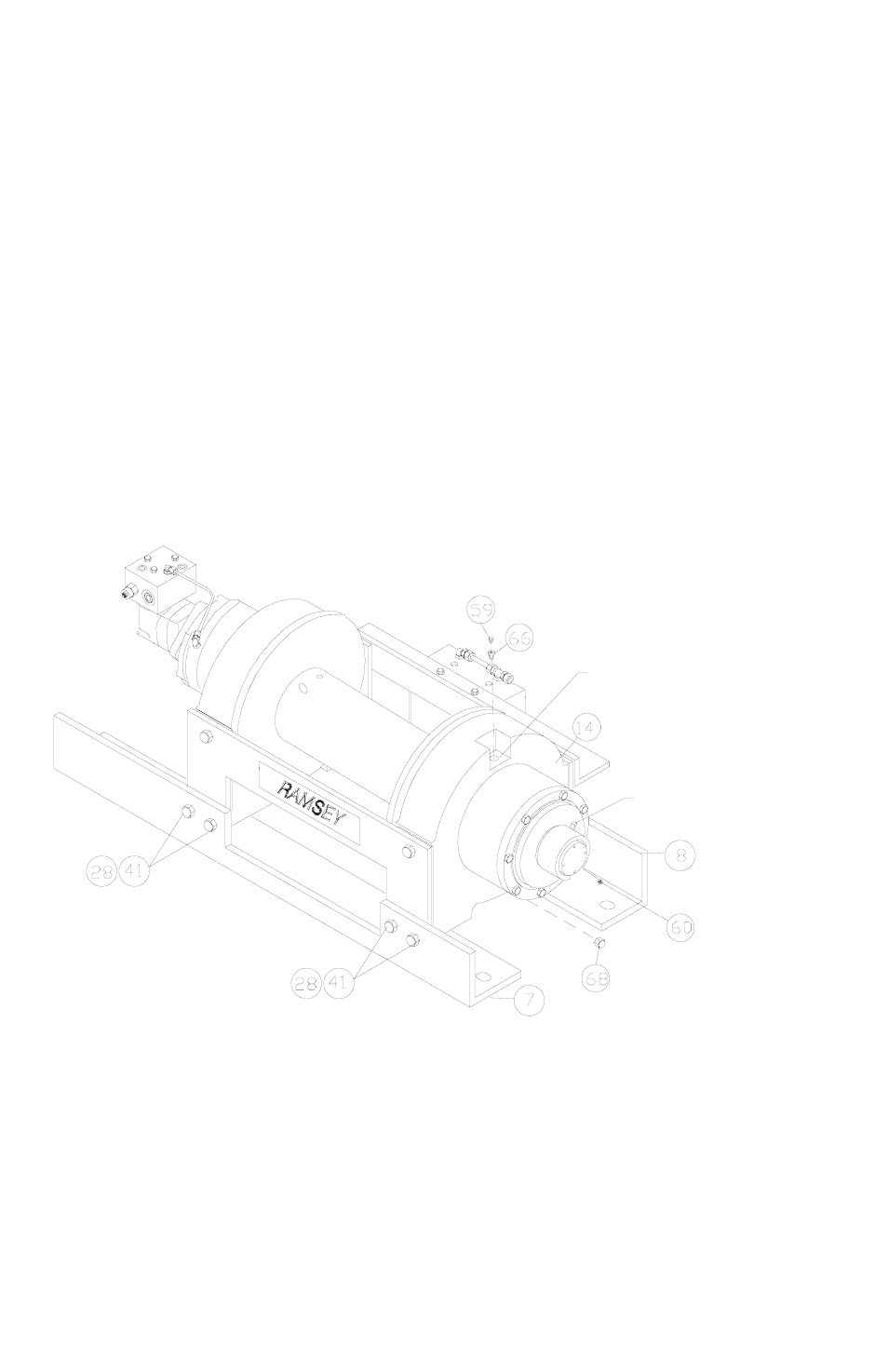

15. Apply Permatex to threads of pipe cap (item #68). Thread pipe cap onto pipe nipple in

bottom of gear housing end bearing (item #13). Pour approx. 1.75 pints of SAE 80W-140

oil into end bearing. Check oil level by removing oil plug noted below. Insert relief fitting

(item #59) and thread reducer (item #66) into end bearing at oil fill hole.

Install winch and connect pressure lines. Apply at least 230 PSI pressure to release brake

and verify that brake releases, by observing that the winch drum rotates.

16. Check proper operation of clutch by applying air pressure to clutch air cylinder to disen-

gage clutch. Verify that winch freespools. Re-engage clutch. A loud noise should be heard

when clutch engages. Winch drum should not freespool.

17. Operate winch forward and reverse to verify that drum rotates.

18. Place winch and frame into angles (Item #7 & #8) and attach using capscrews and lock-

washers shown below. Tighten (4) upper-most capscrews securely, check rotation of

cable drum. Tighten (8) lower-most capscrews securely, check rotation of cable drum.

Torque the (4) upper-most capscrews to 85 ft.lbs. each, then the (8) lower-most capscrew

to 85 ft.lbs. each. Make sure cable drum assembly rotates freely at this point.

OIL FILL HOLE

OIL LEVER HOLE

13