Ramsey Winch H-800 DOW-LOK W/25000 LB RATING User Manual

Page 5

5

CABLE INSTALLATION

The Ramsey Model H-800 "Dow-Lok

®

” winch has two tapered pockets cast into the drum.

One pocket is for installations with the wire rope wound over the drum. The other pocket is

for an underwound wire rope.

1. Slide the wire rope through narrow end of the pocket against the drum flange.

2. Wrap the wire rope around the anchor "puck" and pull the wire rope and anchor back into

the wide end of the pocket.

3. Use a soft hammer to drive the back side of the wire rope, firmly seating the wire rope

and anchor, into the pocket.

The wire rope can easily be removed from the drum by driving the anchor out the wide end

of the pocket.

Insert the end of cable, opposite hook end, into the 11/16" dia. hole in drum barrel. Secure

cable to drum barrel, using setscrew furnished with winch. TIGHTEN SETSCREW SECURELY.

Carefully run the winch in the "reel-in" direction, keeping tension on end of cable, spool all

the cable onto the cable drum, taking care to form neatly wrapped layers.

ADJUSTING THE OIL COOLED WORM BRAKE

The oil cooled, fully adjustable, automatic worm brake operates in the worm housing lubri-

cant, all parts being submerged in oil. When the brake wears to the point that the load

begins to drift, the brake can be adjusted as follows:

1. Loosen the adjusting screw lock nut.

2. Tighten the brake by turning the adjusting screw clockwise. CAUTION: Only 1/4 turn is

usually required to adjust the brake. Over-tightening can cause over-heating, and damage

to the brake parts. Tighten the lock nut after adjustment is completed.

If the brake does not respond to adjustment then a new leaf spring and brake disc is needed.

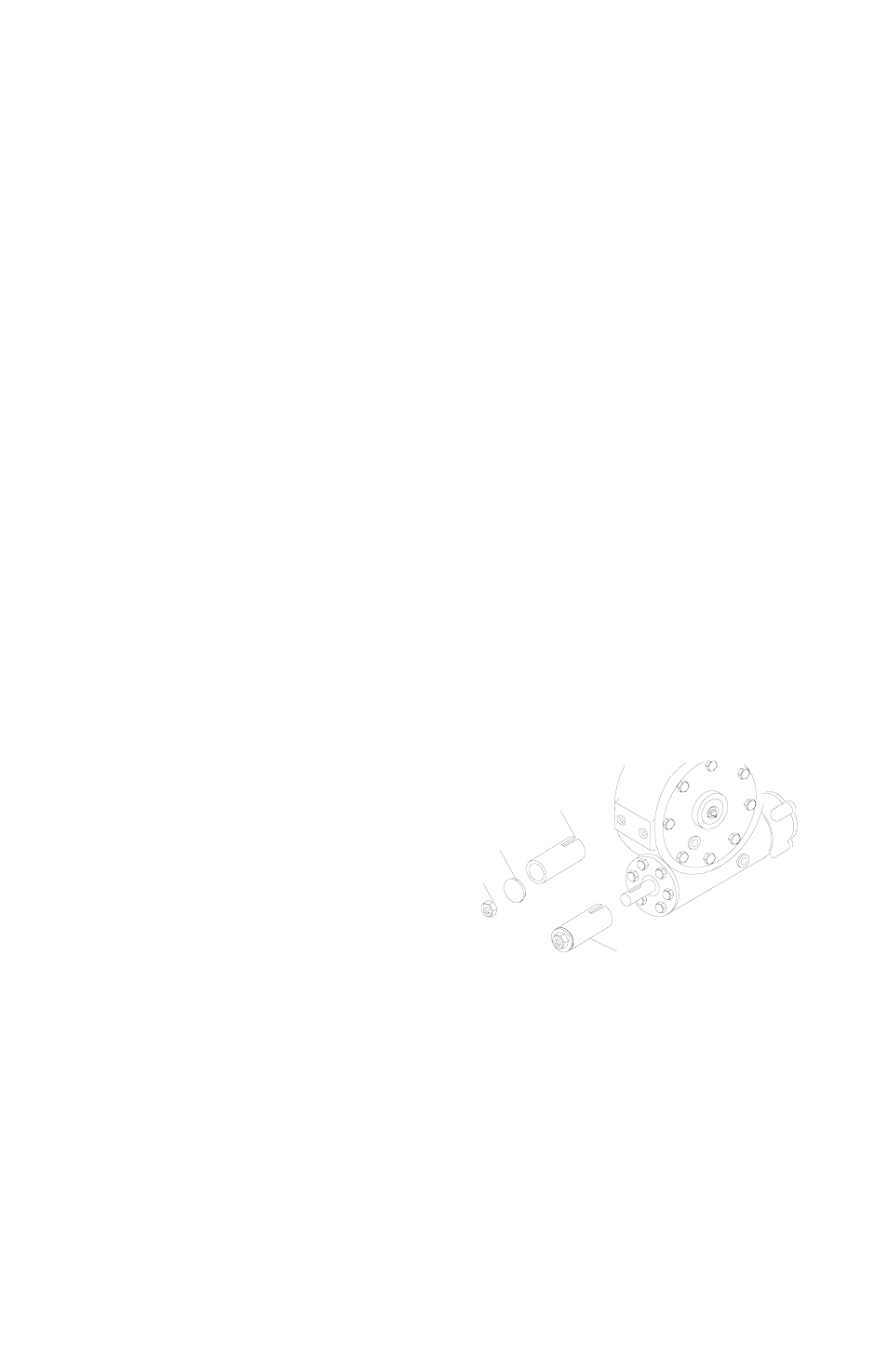

A torque wrench can be equipped with a spe-

cial adapter to fit the input shaft (worm) of

the winch. The adapter can be made by

welding a nut to the end of a piece of tubing

as shown in the following figure.

After welding the cap and nut to the tubing,

slot the tubing, as shown. This will allow the

special adapter to slide over the keyway and

will then act as a large socket. A torque

wrench can the be used to apply the proper torque. Turn the torque wrench so that the drum

turns in the spool out direction or lowering direction. The torque rating for the brake on the

Model H-800 Dow-Lok® should be 50 to 55 ft-lbs. If torque wrench does not show the

proper value as it turns, then the worm brake adjusting bolt should be turned clockwise 1/4

turn. Each time the adjusting bolt is turned, check the torque reading. Continue this proce-

dure until the proper torque reading is achieved. Then tighten the lock nut.

ADAPTER

CAP

NUT

TUBING

SOCKET