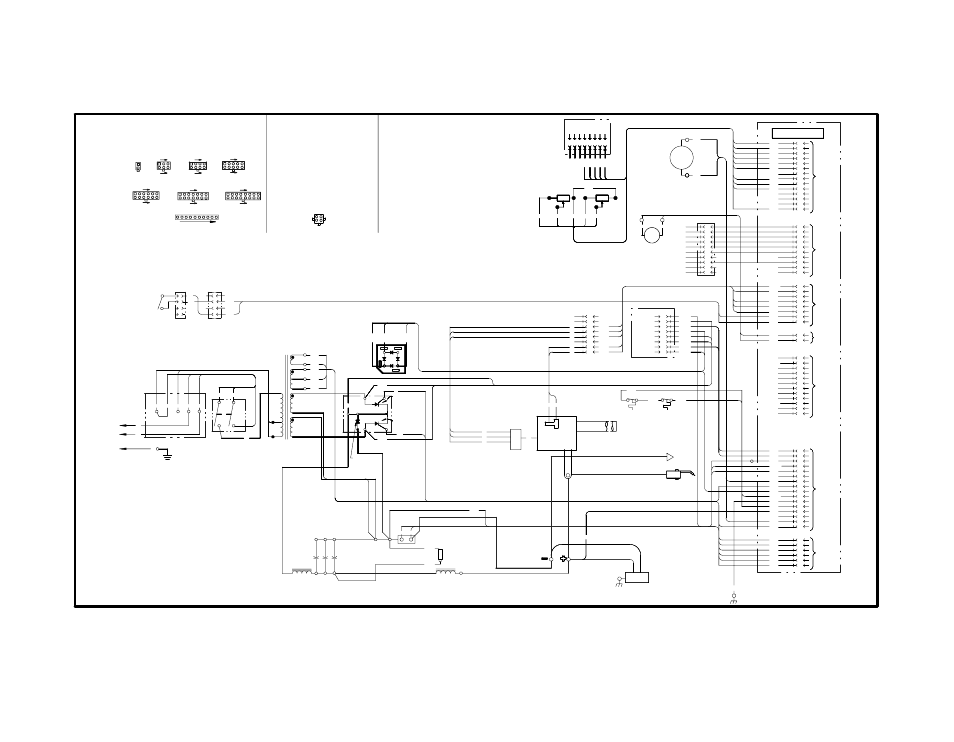

Lincoln Electric IMT636 POWER MIG 255 User Manual

Page 47

F-3

L11979

A.01

COLOR CODE:

ELECTRICAL SYMBOLS PER E1537

GENERAL INFORMATION

4

5

J7

9

8

7

6

265

263

260

261

U - BLUE

R - RED

W - WHITE

B - BLACK

INDICATES CONNECTOR CAVITY NO.

262

267

264

OUTPUT

CHOKE

POWER FACTOR

ENHANCEMENT

CHOKE

204B

FO

R

SP

O

O

L

G

UN

O

PT

IO

N

SECONDARY VOLTAGES SHOWN

ARE NO LOAD RMS VALUES

WIRE

DRIVE

MOTOR/

GEARBOX

1

2

3

10

C3

C1

205

206S

206B

R1

SCR HEATSINK

ASSEMBLY

THERMOSTAT

116.6V

14.2V

14.2V

28.4V

C2

+

+

+

C1 THRU C3

31,000 MFD

50V

15 OHMS

100 W

B

+

-

320B

1

J10

J10

390

392

J1

J4

J6

J8

J9

J7

10

J2

J5

1

3

J3

CAVITY NUMBERING SEQUENCE

(COMPONENT SIDE OF P.C. BOARD)

251

206

FOR TIMER

OPTION

28.4V

J9

W

T

A

C

H

R.F. FILTER

SCR HEATSINK

ASBLY

SCR 2

G1

208S

204S

G2

SCR 1

209S

1

2

3

208S

208

208R

209S

204S

8

7

6

5

4

209R

209

252

WIRE FEED

SPEED

R3

256

8

6

5

1

ARC

VOLTAGE

252

254

253

256

R4

254A

55

0

55

1

4

2

7

WIRE FEED

SPEED

3

R3

DISPLAY

BOARD

51

5

55

2

50

0

8

4

7

6

3

5

2

1

ARC

VOLTAGE

WIRE FEED

SPEED

252

254

253

256

R4

254A

DISPLAY

BOARD

50

0

51

5

55

1

55

2

55

0

R3

POWER

TRANSFORMER

LINE

SWITCH

S1

SCR 1

G1

208S

G2

204S

L2

L1

H4

H2

H3

L1

208V

230V

H1

H4

H1

RECONNECT

PANEL

TO GROUND PER

NATIONAL ELECTRICAL

CODE

W

SCR 2

ASBLY

SCR HEATSINK

209S

L2

B

WIRE FEED

SPEED

253

R4

ARC

VOLTAGE

252

254

256

R3

254A

G2

SCR 1

SCR HEATSINK

ASBLY

SCR 2

204S

209S

G1

208S

SCR 2

ASBLY

SCR HEATSINK

SCR 1

G2

G1

208S

204S

209S

-

+

208R

209R

-

+

254A

R3

252

254

256

WIRE FEED

SPEED

8

7

6

5

4

3

2

1

ARC

VOLTAGE

DISPLAY

BOARD

253

R4

50

0

51

5

55

0

55

1

55

2

209R

+

-

208R

354

J11

1

2

3

4

325

324

325

4

2

GUN

TRIGGER

324

5

2

3

2

4

1

2

3

2

5

5

2

3

4

7

11

6

3

8

9

2

5

4

J8

252

550

254

500

J4

4

7

6

14

11

1

J5

J6

1

1

11

10

9

8

6

GND

X6

X5

515

206B

B

392

2

3

4

7

8

9

10

3

5

206

205

320

326

541A

543

SCI

SCI

515

206A

8

6

14

15

16

6

325A

5

W

206S

207

353

X8

325B

X9

352

4

10

12

13

7

12

354

G2

204

G1

X7

390

325

555

1

J2

6

7

8

9

J1

10

1

515B

324

208

CONTROL BOARD

12

13

1

J3

253

251

552

551

256

209

GND

352

353

252

R4

254A

256

253

254

DISPLAY

BOARD

WIRE FEED

SPEED

R3

8

7

6

5

4

3

1

ARC

VOLTAGE

51

5

2

55

1

55

2

55

0

50

0

209R

+

354

208R

-

515B

555

206B

253

R4

254

256

254A

ARC

VOLTAGE

B

W

L2

H4

H3

H2

L1

230V 208V

RECONNECT

PANEL

254A

H4

H2

L1

208V

RECONNECT

PANEL

H3

230V

L1

H1

L2

H4

H1

W

B

LINE

SWITCH

S1

L2

POWER

TRANSFORMER

204S

208S

G1

SCR HEATSINK

ASBLY

SCR 2

G2

209S

L2

L1

H4

H1

H1

H3

230V

H2

H4

208V

L1

RECONNECT

PANEL

W

LINE

SWITCH

S1

L2

B

SNUBBER

BOARD

X2

H1

ASBLY

SCR HEATSINK

D1

R.F. FILTER

209S

X8

D2

BAFFLE

MOUNTED

RECTIFIER

DIODE

BRIDGE

354

+

G1

208S

204S

SCR 2

H1

X3

H2

X4

H3

POWER

TRANSFORMER

H3

H2

L1

230V 208V

L2

RECONNECT

PANEL

G

207

LINE

SWITCH

S1

H4

H1

L2

L1

H4

TO SINGLE PHASE

SUPPLY LINE

B

W

X9

X5

X5

X6

X6

X7

X7

X1

X9

X8

208R

-

209R

TO

WORK

SCR 1

G2

352

353

FAN

MOTOR

TO

WORK

J3

252

254

253

256

TO

WORK

207

R.F. FILTER

50

0

51

5

55

0

55

1

ARC

VOLTAGE

252

254

253

256

R3

R4

DISPLAY

BOARD

254A

55

2

WIRE FEED

SPEED

8

7

6

5

4

3

2

1

254A

252

254

253

256

R3

R4

ARC

VOLTAGE

WIRE FEED

SPEED

325B

OUTPUT CHOKE

THERMOSTAT

320

B

R

U

J11

**

N.A. WELDING CABLE MUST BE OF PROPER CAPACITY FOR THE

FUTURE APPLICATIONS.

NOTES:

CONDUCTOR STRAP AND WORK STUD.

OFF AND REVERSE LEAD CONNECTIONS AT CABLE

"POSITIVE". TO CHANGE POLARITY, TURN THE UNIT

CURRENT AND DUTY CYCLE OF IMMEDIATE AND

N.B. THIS DIAGRAM SHOWS THE "ELECTRODE" POLARITY

GAS

SOLENOID

CONTROL BOARD

PO

POWER

WER MIG

MIG 255 (20

255 (2088//230

230 V

V CODE 10990 AND ABOVE)

CODE 10990 AND ABOVE)

2

1

5

8

4

1

8

1

9

16

1

3

4

6

8

1

14

7

1

12

7

6

10

6

5

1

CAVITY

1

**

(NON-LEAD SIDE OF CONNECTOR)

2

3 4

NUMBERING SEQUENCE

J11

1

2

3

8

7

6

5

4

W

B

B

R

U

W

B

J12

J12

NOTE: This diagram is for reference only.

It may not be accurate for all machines covered by this manual. The specific diagram for a particular code is pasted

inside the machine on one of the enclosure panels. If the diagram is illegible, write to the Service Department for a replacement. Give the equipment code number..