Installation, General description, Design features – Lincoln Electric IM10046 VRTEX 360 User Manual

Page 14

A-4

INSTALLATION

A-4

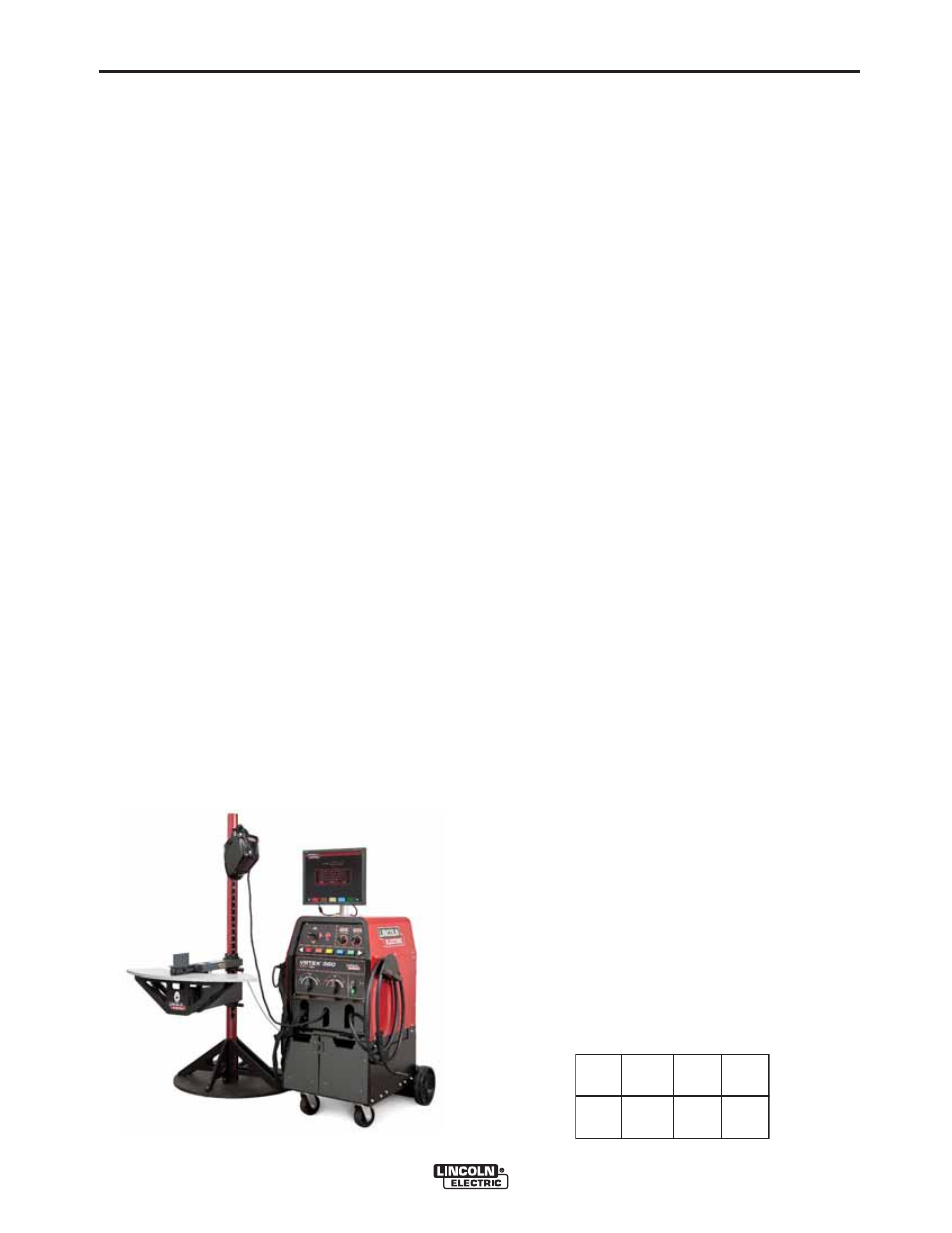

GENERAL DESCRIPTION

The VRTEX

®

360 is a

Virtual Welding Training System

and VRAW

®

(Virtual Reality Arc Welding) Solution.

This computer controlled interactive system simulates

arc welding through the use of realistic puddle graph-

ics and sounds. This training system simulates multi-

ple arc welding processes on a wide variety of weld

joint configurations. The VRTEX

®

360

represents the

next generation of Virtual Reality (VR) welding train-

ing.

DESIGN FEATURES

HARDWARE OVERVIEW:

• Virtual Welding Machine, including:

- Monitor

- Coupon Drawer (back drawer)

- VR GMAW/FCAW Gun

- VR SMAW Device

- VR GMAW/FCAW Gun Holder

- VR SMAW Device Holder

- VR Helmet w/Face Mounted Display (FMD)

- Arm

- Speakers

- Five VR Coupons - Flat Plate

T-Joint

Groove Joint

2” Pipe XXS

6” Pipe Schedule 40

• Stand, including:

- Post

- Table

- Pins

- Base

- Weights

HARDWARE UNCRATING:

TOOLS NEEDED

3/8” (9.5 mm) Wrench

3/16” (4.8 mm) Allen Wrench

Phillips Screwdriver

1. Decide on a location for your unit.

NOTE: The system requires approximately 8ʼ L x 8ʼ

D x 8ʼ H (2.4 m L x 2.4 m D x 2.4 m H) of

space. Keep at least 3 feet in all directions of

both the stand and VR weld machine free from

obstruction. In addition, be conscious of where

you are placing the unit to avoid magnetic fields,

conductive, and high frequency objects and

processes.

NOTE: Avoid setting up the VRTEX

®

360 near high

frequency TIG machines and power sources.

Having these types of objects in the area can

cause interference and result in increased jitter

and/or distortion in the motion tracking.

For best results, do not install VRTEX

®

360

machine in the welding lab. Electrical interfer-

ence from power lines, though generally small,

can be present. Therefore all electrical power or

lighting wiring within 50 feet of the welding area

shall be enclosed in grounded rigid metallic con-

duit. In the event the VRTEX

®

360

is affected by

interference, it is the user's responsibility to take

steps to isolate and/or eliminate the interfer-

ence.

An uninterruptible power supply (UPS) may be

required for the protection of the system from

power irregularities or disruption.

It is strongly recommended that a single or

Multi-Outlet surge protector be used to protect

the machine from any unwanted voltages

above a safe threshold.

MULTIPLE SYSTEM INSTALLATIONS

If multiple systems are required to operate together in

one location, a unique frequency transmitter can be

installed during the manufacturing process at Lincoln

Electric to reduce potential interference between sys-

tems. AD1332-1, -4 systems have a standard frequency

source installed. AD1332-2, -5 systems have an alter-

nate frequency source installed. For multiple system

installations, alternate the -1, -4 and -2, -5 systems for

best operation:

For Example: If 8 systems are to be installed in the VR

welding lab, the standard and alternate frequencies

should be positioned as seen below.

VRTEX

®

360

-1/-4

-1/-4

-1/-4

-1/-4

-2/-5

-2/-5

-2/-5

-2/-5