Installation – Lincoln Electric IM10057 POWER WAVE STT MODULE (CE) User Manual

Page 13

A-4

INSTALLATION

POWER WAVE

®

STT

®

MODULE (CE)

A-4

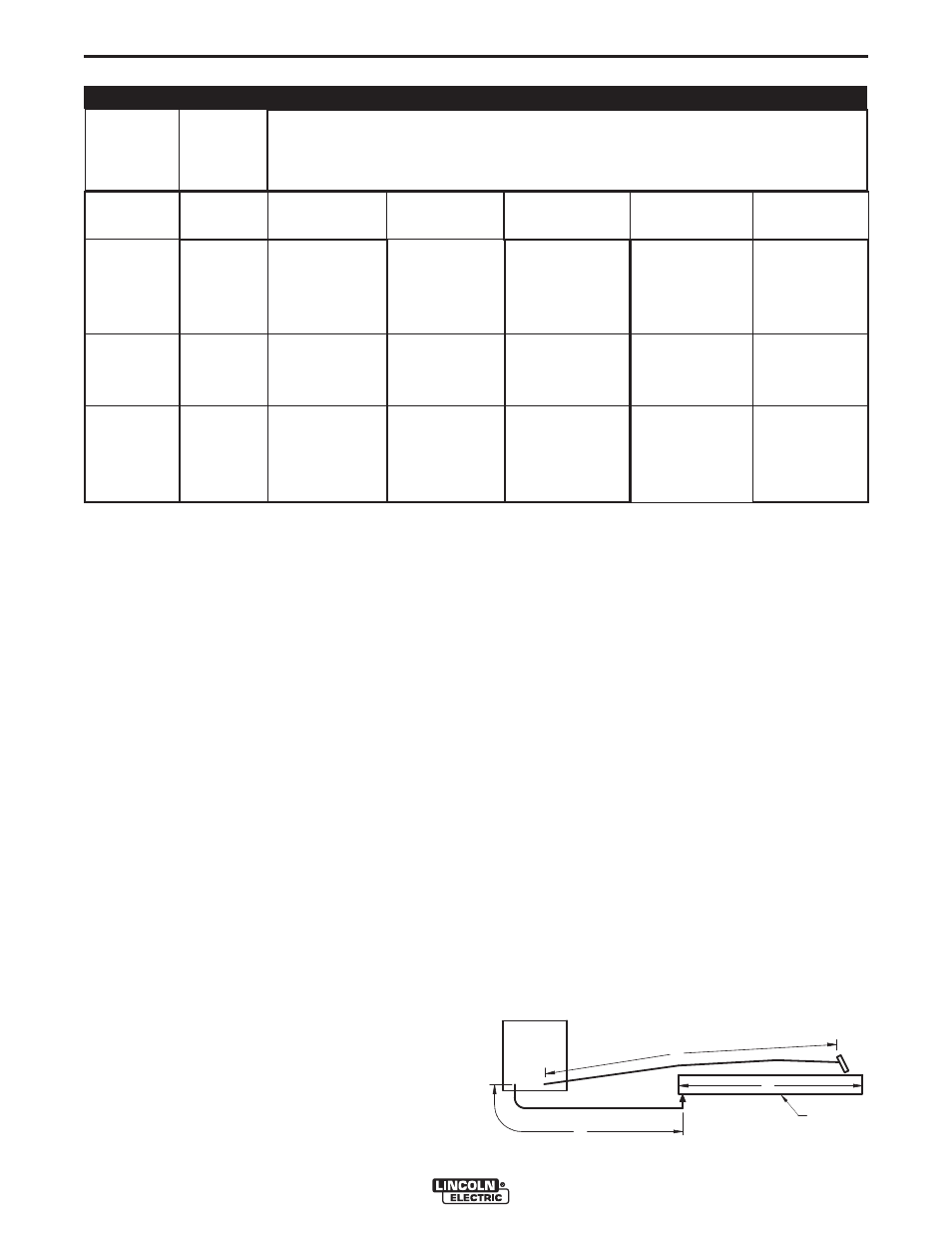

CABLE INDUCTANCE AND ITS EFFECTS

ON WELDING

Excessive cable inductance will cause the welding

performance to degrade. There are several factors

that contribute to the overall inductance of the cabling

system including cable size, and loop area. The loop

area is defined by the separation distance between

the electrode and work cables, and the overall welding

loop length. The welding loop length is defined as the

total of length of the electrode cable (A) + work cable

(B) + work path (C) (see Figure A.3 below). To mini-

mize inductance always use the appropriate size

cables, and whenever possible, run the electrode and

work cables in close proximity to one another to mini-

mize the loop area. Since the most significant factor in

cable inductance is the welding loop length, avoid

excessive lengths and do not coil excess cable. For

long work piece lengths, a sliding ground should be

considered to keep the total welding loop length as

short as possible.

GENERAL GUIDELINES

• Select the appropriate size cables per the “Output

Cable Guidelines” (See Table A.1. Excessive

voltage drops caused by undersized welding

cables and poor connections often result in unsat-

isfactory welding performance. Always use the

largest welding cables (electrode and work) that

are practical, and be sure all connections are clean

and tight.

Note: Excessive heat in the weld circuit indicates

undersized cables and/or bad connections.

• Route all cables directly to the work and wire feed-

er, avoid excessive lengths and do not coil excess

cable. Route the electrode and work cables in

close proximity to one another to minimize the loop

area and therefore the inductance of the weld cir-

cuit.

• Always weld in a direction away from the work

(ground) connection.

See Table A.1 for copper cable sizes recommended

for different currents and duty cycles. Lengths stipulat-

ed are the distance from the welder to work and back

to the welder again. Cable sizes are increased for

greater lengths primarily for the purpose of minimizing

cable drop.

OUTPUT CABLE GUIDELINES

TABLE A.1

CABLE SIZES FOR COMBINED LENGTHS OF ELECTRODE AND WORK CABLES

(RUBBER COVERED COPPER - RATED 75°C)**

Percent

Duty

Cycle

60

100

20

40 & 30

30

40

60

100

60

100

60

60

100

60

2

2

4 or 5

3

3

2

1

1

1

2/0

1/0

2/0

3/0

2/0

2

2

3

3

3

2

1

1

1

2/0

1/0

2/0

3/0

2/0

2

2

2

2

2

1

1

1

1

2/0

2/0

2/0

3/0

3/0

1

1

1

1

1

1

1

1

1/0

2/0

2/0

3/0

3/0

3/0

1/0

1/0

1/0

1/0

1/0

1/0

1/0

1/0

2/0

3/0

3/0

4/0

4/0

4/0

200

200

225

225

250

250

250

250

300

325

350

400

400

500

Amperes

0 to 50 Ft.

50 to 100 Ft. 100 to 150 Ft. 150 to 200 Ft. 200 to 250 Ft.

** Tabled values are for operation at ambient temperatures of 40°C and below. Applications above 40°C may require cables larger than

recommended, or cables rated higher than 75°C.

B

A

C

POWER

WAVE

FIGURE A.3

WORK