Installation, Caution, Caution warning – Lincoln Electric IM10057 POWER WAVE STT MODULE (CE) User Manual

Page 12: Connection between power source and stt, Module (arclink, And differential i/o pigtails), Electrode and work connections

A-3

INSTALLATION

POWER WAVE

®

STT

®

MODULE (CE)

A-3

Regarding cable placement, best results will be

obtained when control cables are routed separate

from the weld cables. This minimizes the possibili-

ty of interference between the high currents flow-

ing through the weld cables, and the low level sig-

nals in the control cables. These recommenda-

tions apply to all communication cables including

ArcLink

®

connections.

------------------------------------------------------------------------

CONNECTION BETWEEN POWER

SOURCE AND STT

®

MODULE (ARCLINK

®

AND DIFFERENTIAL I/O PIGTAILS)

The pigtail connections on the STT

®

Module include all

signal and power lines required for proper operation.

With the STT

®

Module securely fastened to the power

source, connect the pigtails to their respective recep-

tacles on the back of the power source per the con-

nection diagram located in the “Installation Section”.

Special Instructions:

K2921-1

A special ArcLink

®

and Differential I/O receptacle kit

is provided with the STT

®

Module for installation into

the host power source. Follow the instructions pro-

vided with the kit. (reference instruction sheet

M22499).

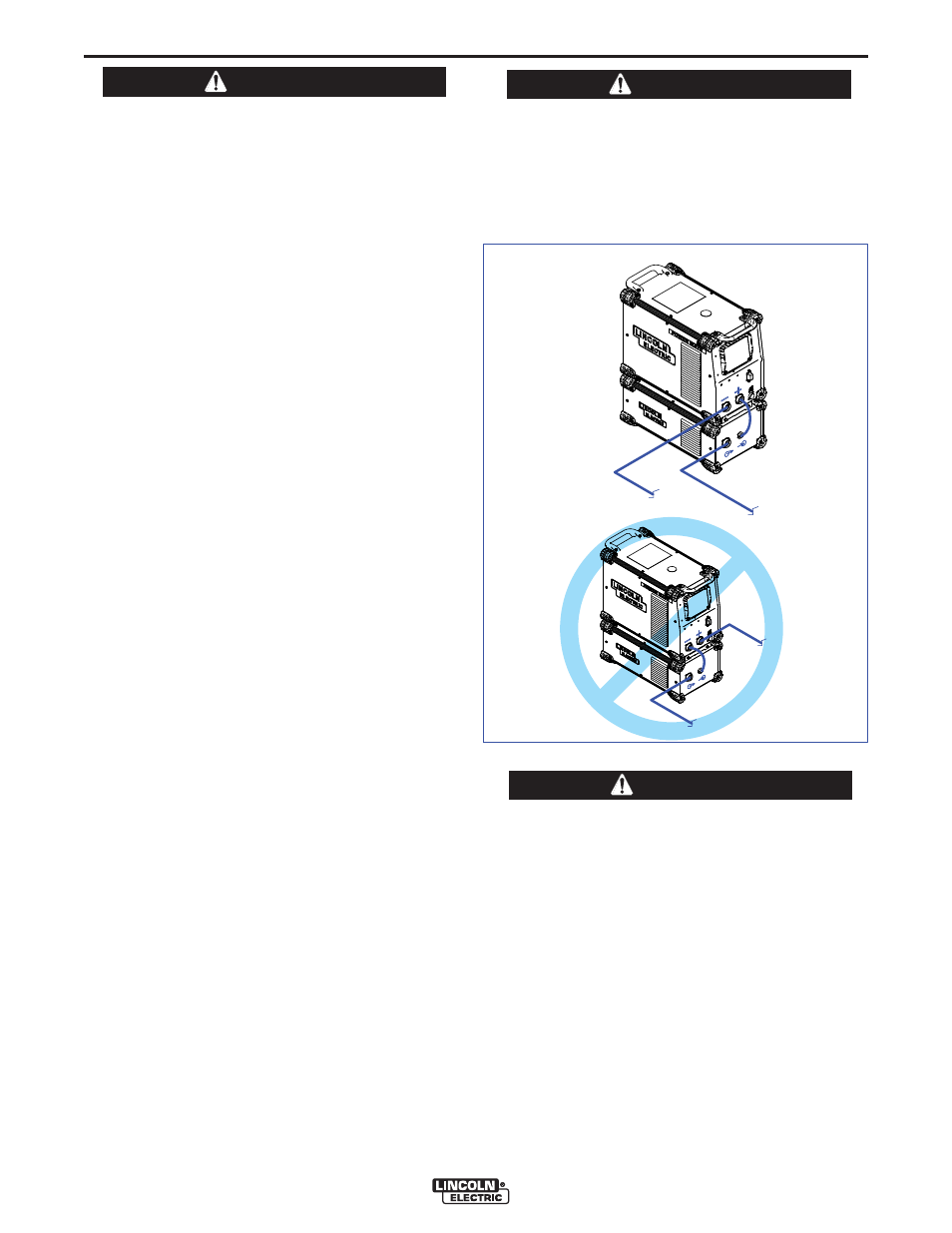

ELECTRODE AND WORK CONNECTIONS

Connect the electrode and work cables per the con-

nection diagrams included in this document. Size and

route the cables per the following:

• Positive Electrode Polarity: Most welding appli-

cations run with the electrode being positive (+).

For those applications, connect the electrode cable

between the wire drive feed plate and the output

stud on the STT Module. Connect a work lead from

the negative (-) power source output stud to the

work piece per the Connection Diagram.

(See Figure A.5)

• Negative Electrode Polarity: The STT process

CANNOT be run using negative electrode polarity.

However, for processes other than STT requiring

negative polarity, such as some Innershield appli-

cations, the electrode and work connections

should be reversed at the load, NOT at the input to

the STT Module. Connect the electrode cable to

the negative (-) stud of the power source, and work

cable to the output stud of the STT Module per the

Negative Polarity Connection Diagram.

(See Figure A.2)

Negative electrode polarity operation may require

reconfiguration of the power source voltage sense

leads. See the Remote Sense Lead section in the

power source instruction manual for further

details.

------------------------------------------------------------------------

For additional Safety information regarding the elec-

trode and work cable set-up, See the standard

“SAFETY INFORMATION” located in the front of the

Instruction Manuals.

Never reverse the polarity at the input of the STT

Module (DO NOT connect the negative stud of the

power source to input stud of the STT Module).

This may result in damage to the STT Module!

------------------------------------------------------------------------

CAUTION

CAUTION

WARNING

TO ELECTRODE

(FEEDER)

TO WORK

TO WORK

TO ELECTRODE

(FEEDER)

NEGATIVE POLARITY

CONNECTION

(

NOT TO BE USED FOR

STT PROCESS)

FIGURE A.2