Troubleshooting, Caution – Lincoln Electric IM10090 ARC TRACKER User Manual

Page 25

E-2

TROUBLESHOOTING

E-2

ARC TRACKER™

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your

Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

CAUTION

Observe all Safety Guidelines detailed throughout this manual

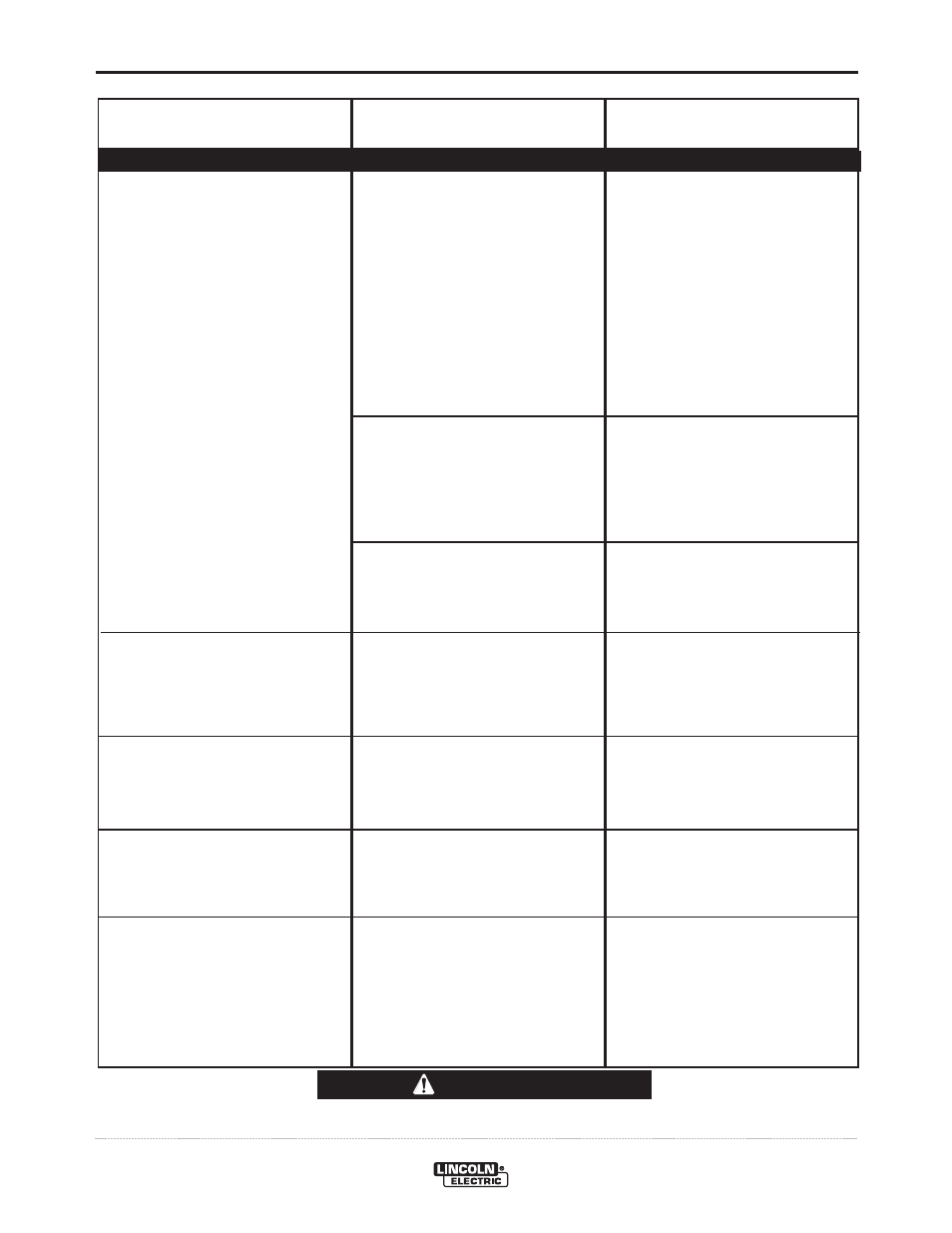

PROBLEMS

(SYMPTOMS)

POSSIBLE

CAUSE

RECOMMENDED

COURSE OF ACTION

Cannot Connect.

Connection Drops while welding.

Does not display amps, volts, or

energy while welding.

Displays amps and energy, but not

volts.

1. Physical connection.

2. IP address information.

3. Ethernet Speed.

1. Cable Location.

1. Weld circuit current flowing in

wrong direction.

2. Sense leads not connected prop-

erly or broken.

1. Verify that the correct patch cable

or cross over cable is being used

(refer to local IT department for

assistance).

1a. Verify the cables are fully insert-

ed into the bulk head connector.

1b. The LED under the PC board

ethernet connector will be lit

when the machine is connected

to another network device.

2. Use the appropriate PC utility to

verify the correct IP address infor-

mation has been entered.

2a. Verify no duplicate IP addresses

exist on the network.

3. Verify that the network device

connected to the Power Wave is

either a 10-baseT device or a

10/100-baseT device.

1. Verify Network cable is not locat-

ed next to current carrying con-

ductors. This would include input

power cables and welding output

cables.

1. Weld cables must be connected

so current flows into the left weld

terminals and out the right weld

terminals (viewed from rear).

1. Confirm continuity.

2. Red clip lead must be attached to

“+” and black clip lead must be

attached to “-”.

Ethernet