Maintenance – Lincoln Electric IM10090 ARC TRACKER User Manual

Page 21

D-2

MAINTENANCE

D-2

CALIBRATION PROCEDURE

Allow a 5 minute “warm-up” period for all instruments

and power source before applying a load.

Prior to performing the Calibration Procedure, the

accuracy of the ARC TRACKER™ digital meters

should be determined. In Table D.1 Measurement

Results suggested nominal set points are listed. The

power source and resistive load should be set approx-

imately to these voltage and current set points, e.g. 28

V @ 200 A, 36 V @ 400 A, etc. The reference meter

readings should be compared to the ARC TRACK-

ER™ digital meters.

The reference meter readings should be entered into

Table D.1 in the reference meter value column. The

ARC TRACKER™ meter readings should be entered

into Table 1 in the ARC TRACKER™ as found col-

umn.

The % deviation can be determined by calculation

using the reference meter values and the as found

values (see % Dev Equations). The - limits and + lim-

its can be determined by multiplying the reference

meter values by the desired accuracy of the ARC

TRACKER™ meters (for example, +2% limit = 1.02 x

reference meter value).

If the ARC TRACKER™ digital meters are within the

desired limits, calibration adjustments are not neces-

sary. As left and % deviation values should be

entered into Table D.1. If calibration is required, then

continue with the Adjustment Procedure.

ARC TRACKER™

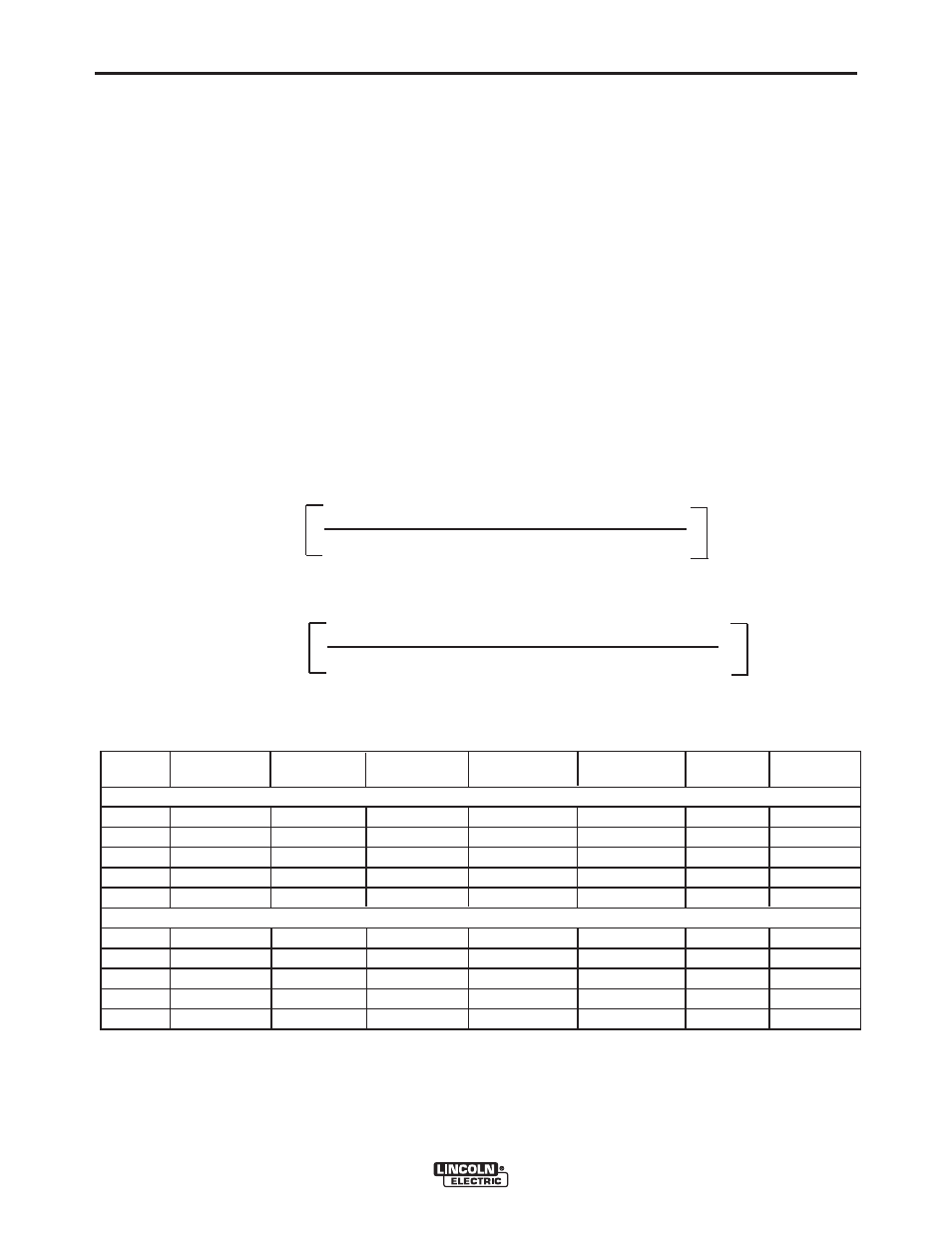

TABLE D.1 MEASUREMENT RESULTS

Nominal

Reference Arc Tracker

% Deviation

Arc Tracker

% Deviation (+) Limit

(-) Limit

Set Point Meter Value

As Found

As Found

As Left

As Left

DC Voltage

DC Amperes

28V

35V

44V

44V

44V

200A

400A

600A

800A

1000A

% Dev Equations:

% Dev

(As Found)

ARC TRACKER™ As Found - Reference Meter Value

Reference Meter Value

=

x100%

% Dev

(As Left)

ARC TRACKER™ As Left - ARC TRACKER™ As Found

Reference Meter Value

=

x100%