Warner Electric Electrical Evaluation User Manual

Electrical evaluation, Warner electric commercial magstop clutch/brake

Warner Electric LLC

31 Industrial Park Road • New Hartford, CT 06057

815-389-3771

•

Fax: 815-389-2582

www.warnerelectric.com

Electrical Evaluation

Warner Electric Commercial MagStop Clutch/Brake

Torque

Resistance

Model

(ft-lb) Nom.

Nm

(ohms)

CMS-175

175

237

2.45 - 2.71

CMS-200

200

271

1.74 - 1.93

Note: If bench tested with 12 volts applied, armature

may not pull away from brakepoles. Rotational motion

is required to engage clutch

Step 2 Measure the supply voltage at the clutch

(Figure 2)

1. Turn engine off.

2. Connect meter leads at the clutch connector.

3. Select meter setting for voltage reading.

4. Make sure wires will not become entangled in rotating

components of clutch.

5. Start engine and engage PTO switch.

6. Measure voltage across the leads at the connectors.

7. Voltage should be 12-14 volts DC. If clutch still

fails to operate, replace the clutch.

8. If voltage is not within 12-14 volt range consult OEMs

service manual.

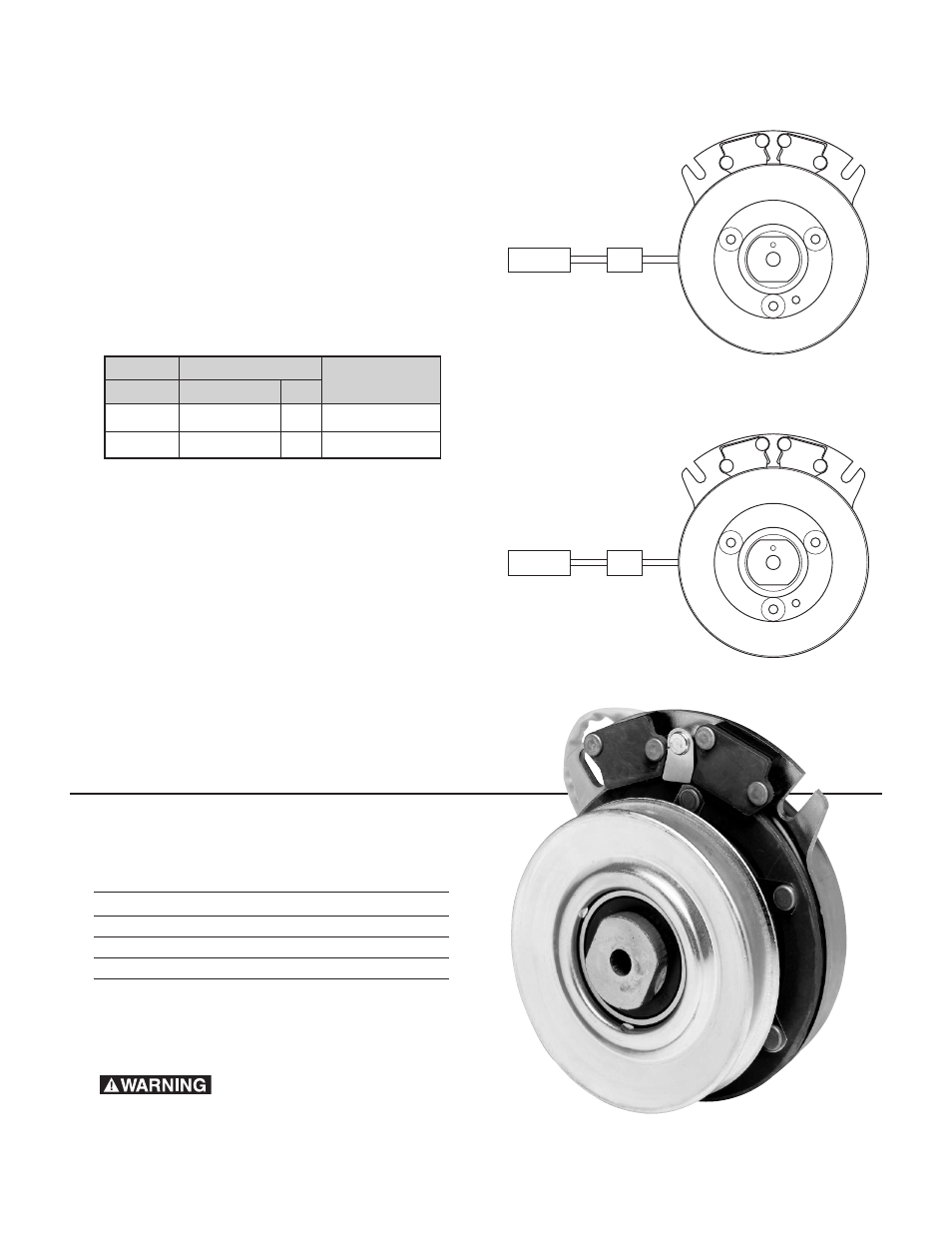

Meter

Connector

Figure 1

Resistance Measurement

Meter

Connector

Figure 2

Voltage Measurement

Installation and operating notes

Clutch mounting bolt torque is critical. Failure to torque mounting bolt to

prescribed values will lead to premature failure of the clutch.

Grade 5 Mounting Bolt

Thread Size

Torque Required

N-m

3/8-24” UNF*

40-45 lb.ft.

54-61

7/16-20” UNF**

50-55 lb.ft.

67-75

M 10 X 1.50

55-60 N-m

55-60

* 3/8 -24 UNF Grade 5 bolt is unacceptable

** 7/16-20 UNF Grade 5 or 8 bolt is acceptable

Note: All values are for dry (unlubricated) plated bolts, please consult

fastener manufacturer if any type of locking element (thread lock

compound, patch etc.) is to be used.

Failure to torque bolt to requirements will

degrade clamping and can allow the clutch to separate from

the shaft, causing risk of personal injury.

Engage deck at less than full engine RPM to increase clutch life. Once

clutch is engaged engine RPM can be increased to full RPM.

819-0459 P-1177-2 8/11

Printed in U.S.A.

Step 1 How to Measure Clutch Coil resistance

(Figure 1)

1. Turn engine and PTO switch off.

2. Disconnect clutch at clutch connector.

3. Select meter setting for ohm reading.

4. Connect meter leads to clutch.

5. Check meter reading and refer to the chart

below for correct clutch resistance reading.

(values are @68° F)

If reading falls in acceptable range proceed to

step 2, if not replace clutch.

Table