Warner Electric Gen 2 Spring-Set Brake Module EM-50 ERS, EM-180 ERS User Manual

Page 2

Mounting the Brake to a Motor

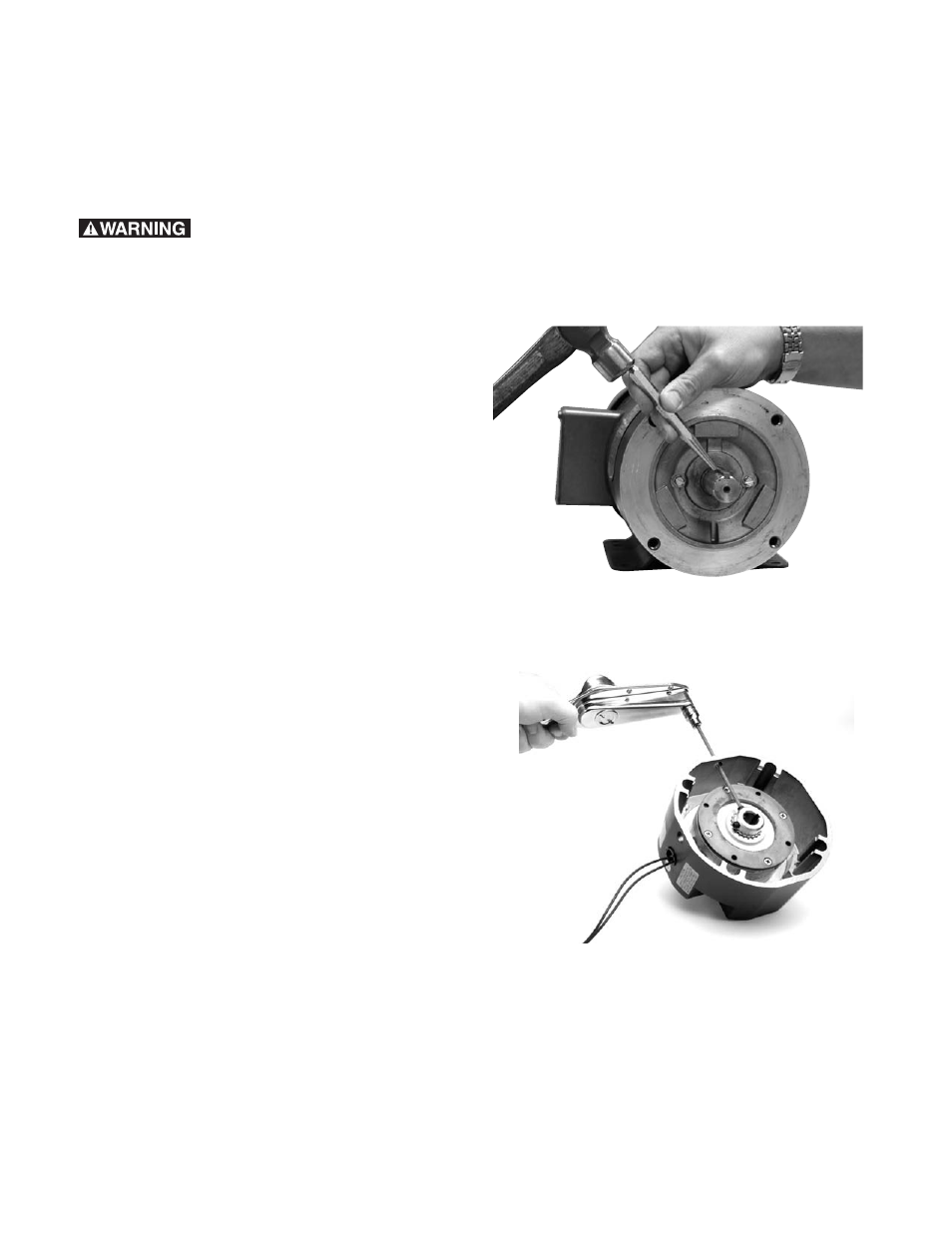

1. Inspect the motor shaft and keyway for

burrs or damage. Remove all burrs and

repair damage so the brake module can

freely slide onto the shaft.

2. Insert the provided input key into the motor

shaft keyway. If necessary, prick punch the

motor shaft keyway to prevent the key from

sliding back while installing the brake

module. (Figure 1)

3. Remove the two plastic plugs with a

screwdriver to gain access to the hub

setscrews. Save these plugs to reinstall

after assembly is complete. The input hub

setscrews and the access holes in the

housing must be aligned to provide hex

wrench access for tightening to the motor

shaft. If they are not already aligned, apply

the rated voltage to the brake coil to release

the brake, and then rotate the shaft until the

setscrews and holes are aligned. (Figure 2)

4. Align the motor shaft and key with the brake

module keyway and slide the module onto

the motor shaft until the housing is in full

contact with the motor face. Do not use

excessive force. If the module does not

freely slide on, remove it and repair any

burrs or damage on the shaft.

2

Warner Electric • 800-825-9050

P-273-11 • 819-0533

Figure 1

Figure 2

T

he Warner Electric Spring-Set Brake Module is designed to function as a holding brake for

NEMA C-face motors. The brake is self-engaging when the power is turned off or unintentionally

interrupted. It is to be mounted between a C-face motor and a C-face gear reducer. Do not apply

overhung or side loads to the output shaft of the Spring-Set Brake Module.

Failure to follow these instructions may result in product damage,

equipment damage, and serious or fatal injury to personnel.