Warner Electric Pump Clutch Installation User Manual

Page 2

2

Warner Electric • 800-825-9050

P-1423 • 819-0388

Positive

Clutch Switch

Clutch

Negative

Figure 1

Failure to follow these

instructions may result in product damage,

equipment damage, and serious or fatal

injury to personnel.

General

This pump clutch has been developed specifically

for use in pump applications. Properly installed, it

will provide maintenance-free service. The clutch

uses a stationary field that does not require slip

rings or brushes.

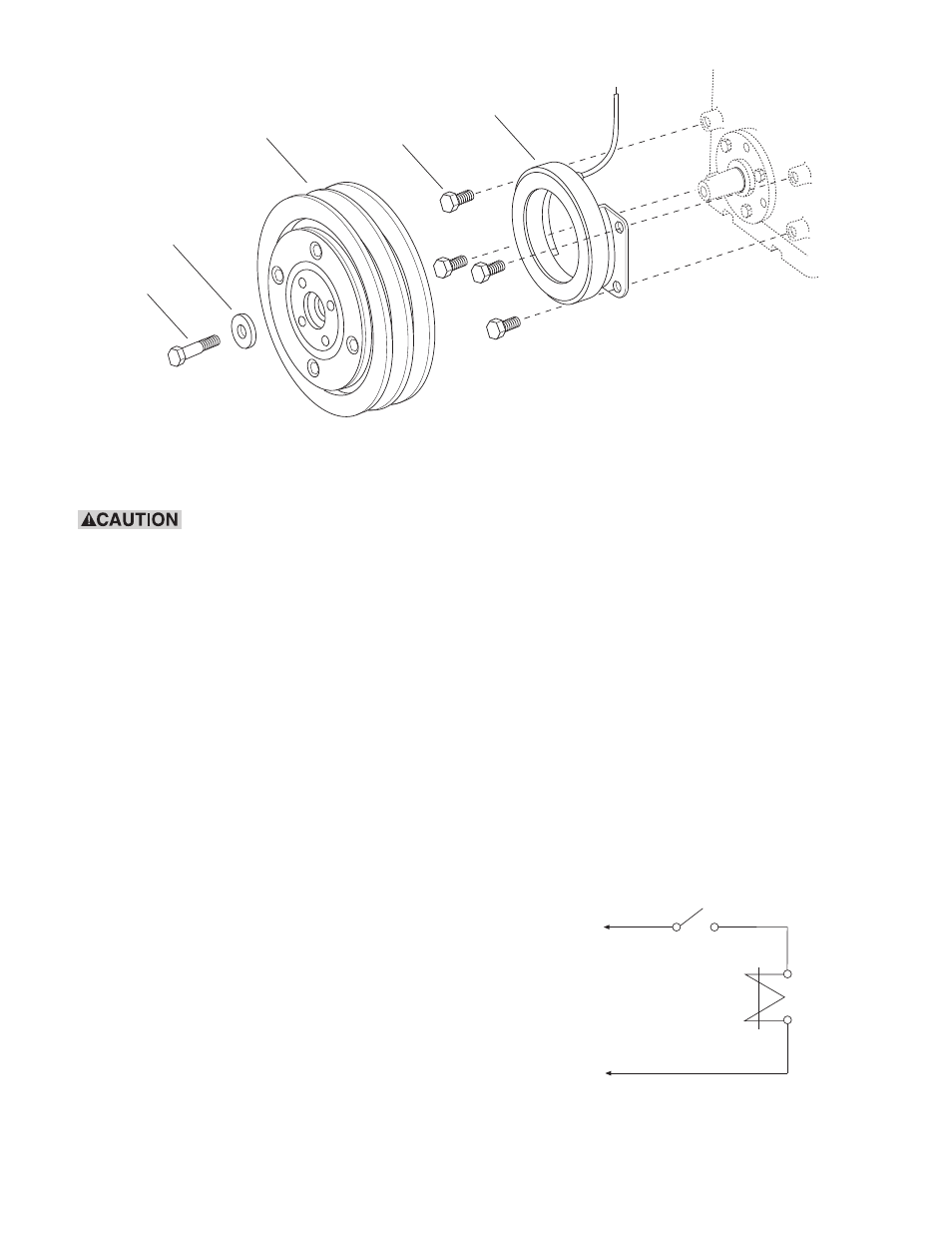

The clutch consists of two major components;

a stationary magnetic field assembly and a

rotor-pulley assembly. The field assembly is

mounted on the pump face. The rotor-pulley is

mounted to the pump shaft and driven by v-belts.

Electricity energizes the clutch field to couple the

clutch magnetically, thus driving the pump

mechanism. De-energizing the field releases

the clutch and uncouples the pump.

Wiring

The coil in the field assembly has a single leadwire

(hot) and is grounded through the field shell. It will

only be necessary to connect this leadwire to the

electrical system as the pump should already be

negatively grounded. Figure 1 shows an example

of a typical system.

Service

The clutch automatically compensates for wear

requiring no adjustments throughout the life of the

clutch.

Do not lubricate the unit. If the clutch

should fail to operate, check the electrical circuit to

be sure the proper voltage is being supplied to the

clutch.

Do not attempt to make any mechanical

adjustments to the clutch.

Cap Screw (5)

Washer (4)

Rotor-Pulley

Assembly (3)

Capscrews &

Lockwashers (2)

Field Assembly (1)

Rotor-Pulley

Assembly

Field

Assembly

Pump

(Not Included)