General – Warner Electric Electric Compressor Clutch Installation User Manual

Page 2

2

Warner Electric • 800-825-9050

P-1426 • 819-0392

Failure to follow these

instructions may result in product damage,

equipment damage, and serious or fatal

injury to personnel.

General

This compressor clutch has been developed

specifically for automobile air conditioning

applications. Properly installed, it will provide

maintenance free service. The clutch, using a

stationary field principle, does not require slip

rings or brushes.

The clutch consists of two major components,

a stationary magnetic field assembly and a

rotor-pulley assembly. The field assembly is

mounted on bosses on the compressor. The

rotor-pulley assembly is mounted to the

compressor crankshaft and driven by V-belts

from the engine crankshaft pulley. Electricity

energizes the clutch field to couple the clutch

magnetically, thus driving the compressor.

De-energization of the field releases the clutch

and uncouples the compressor.

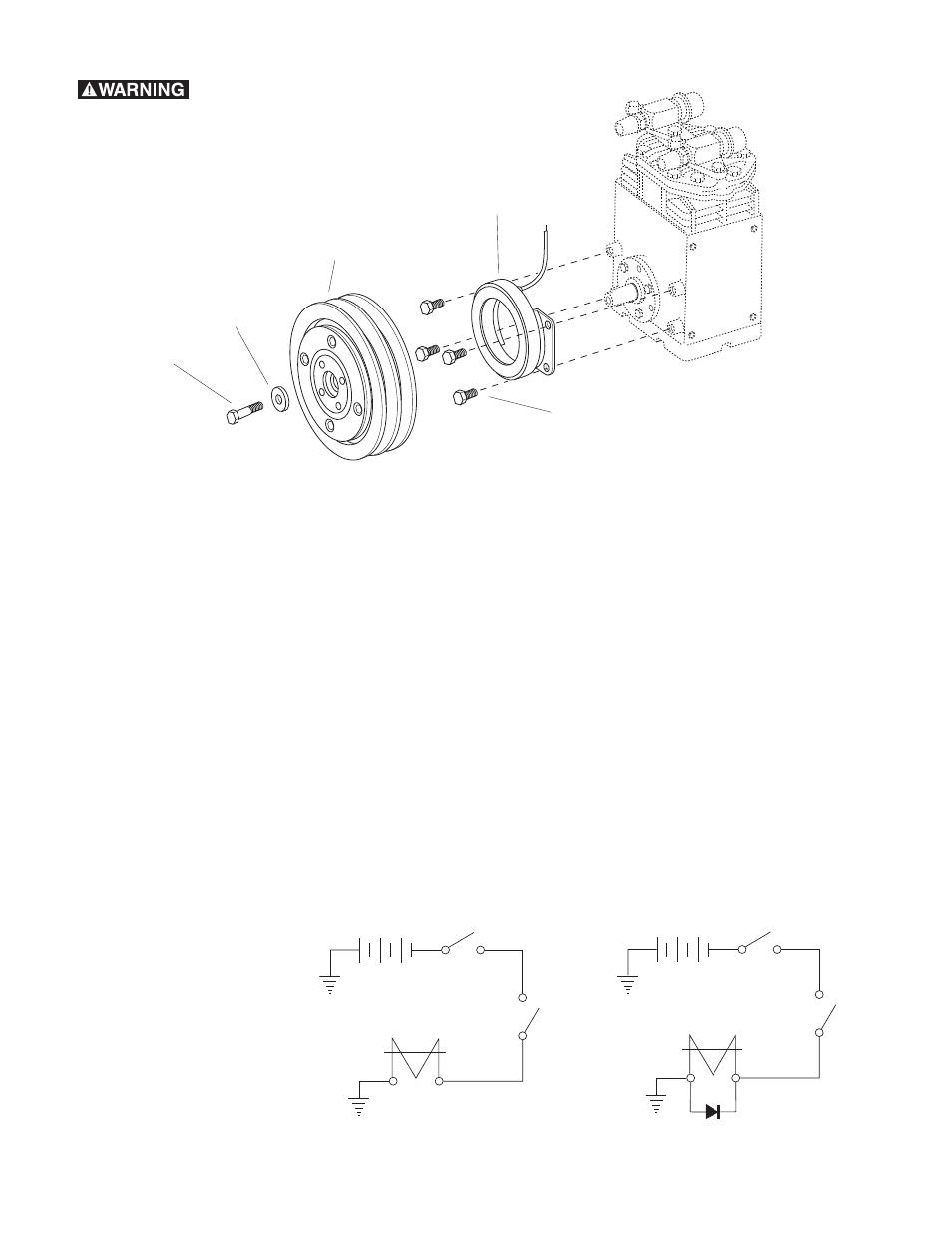

Compressor

Field Assembly

Capscrews

and

Lockwashers

Rotor Pulley

Assembly

Capscrew

Washer

1

2

4

5

3

Installation

Wiring

In most cases, the coil in the field assembly

has a single leadwire (hot) and is grounded to

the field shell. (See Figure 1)

Some newer applications however require the

use of a rectifier diode to protect delicate

electrical components. It is up to the installer

to determine if a diode is necessary.

If a diode is necessaary, one has been

provided with this clutch and must be

connected as directed on enclosed diode

installation instructions. (See Figure 2)

Note: If you are unsure a diode is needed for

your application, install it anyway.

Ignition

Switch

Battery

Clutch

Clutch

Switch

Coil Ground

Figure 1

Ignition

Switch

Battery

Clutch

Clutch

Switch

Coil Ground

Diode

Figure 2