Warner Electric AT Clutches User Manual

Page 4

4

Warner Electric • 800-825-9050

P-217-1 • 819-0372

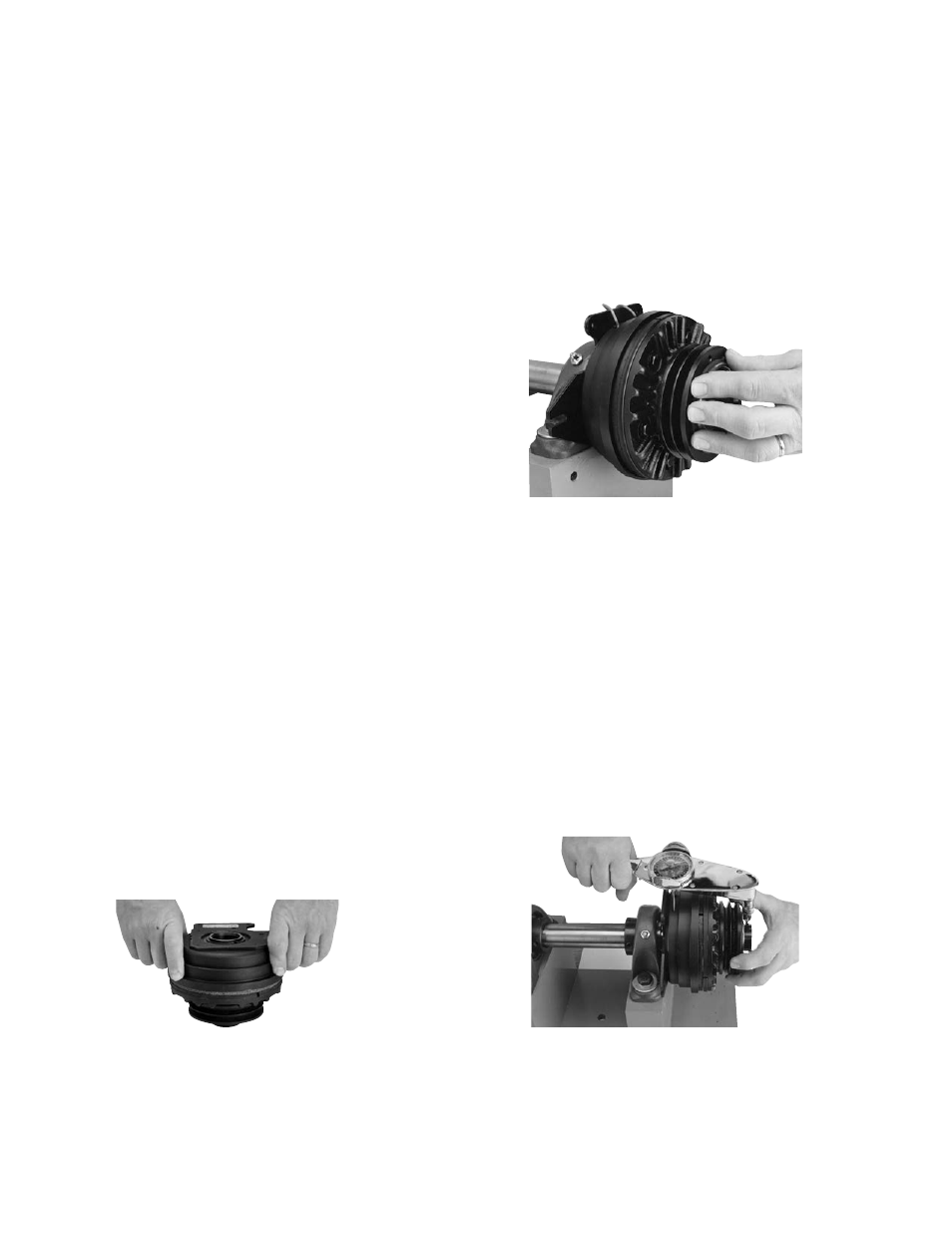

3. Through Bolt Mounting

Note: This method is suitable for pulleys and

sheaves with adequate radial wall thickness

to accommodate through holes.

a. Drill holes through the pulley or sheave

to match the tapped holes on the hub

shoulder of the clutch. The correct bolt

pattern can be found on page 7.

b. Align the through holes in the sheave or

pulley with the tapped holes on the hub

shoulder and gently tap until it seats

against the shoulder.

Note: Installing the keyway and snap ring

are not necessary if the sheave or pulley

is held in place by the through bolt

method.

c. Secure the pulley with capscrews, using

lockwashers or Loctite to assure thread

retention.

4. If used, install the Warner Electric conduit box

or conduit box/CBC-100 control combination in

accordance with instructions furnished with the

conduit box.

5. The Warner Electric patented Autogap™

automatically adjusts the proper operating gap

between the armature and friction face for the

life of these components. The proper gap is

approximately .050". If the armature and

friction face have moved during shipment,

reset the Autogap by pushing the friction face

against the armature. Release. The Armature

will spring back about .050" and the proper

gap is set.

6. Place the AT clutch onto its shaft, making

sure it is properly positioned over the shaft

key. If the clutch is to be mounted vertically,

it must be mounted with the armature fins

down, or improper operation will result.

Note: The Warner Electric special furnished

key must be used with ATC-25-7/8" bore

units.

7. Tighten the hub setscrews into the shaft to

the appropriate torque for your size unit:

Size

Torque

25

80 in.-lbs.

55

160 in.-lbs.

115

275 in.-lbs.

205

275 in.-lbs.

305

620 in.-lbs.

Assure proper alignment of driving and driven

sheave, pulley or sprocket before tightening

the set screws.