Warner Electric AT Brakes User Manual

Page 4

4

Warner Electric • 800-825-9050

819-0334

10. Your AT brake may not achieve its full

torque until after a short “break-in” period.

To break in the brake, cycle it on and off

under full load at operating speed a mini-

mum of ten times in quick succession.

Your AT brake is now ready to run.

Note: Depending on application break in peri-

od may be longer due to load and RPM, and

require more cycles.

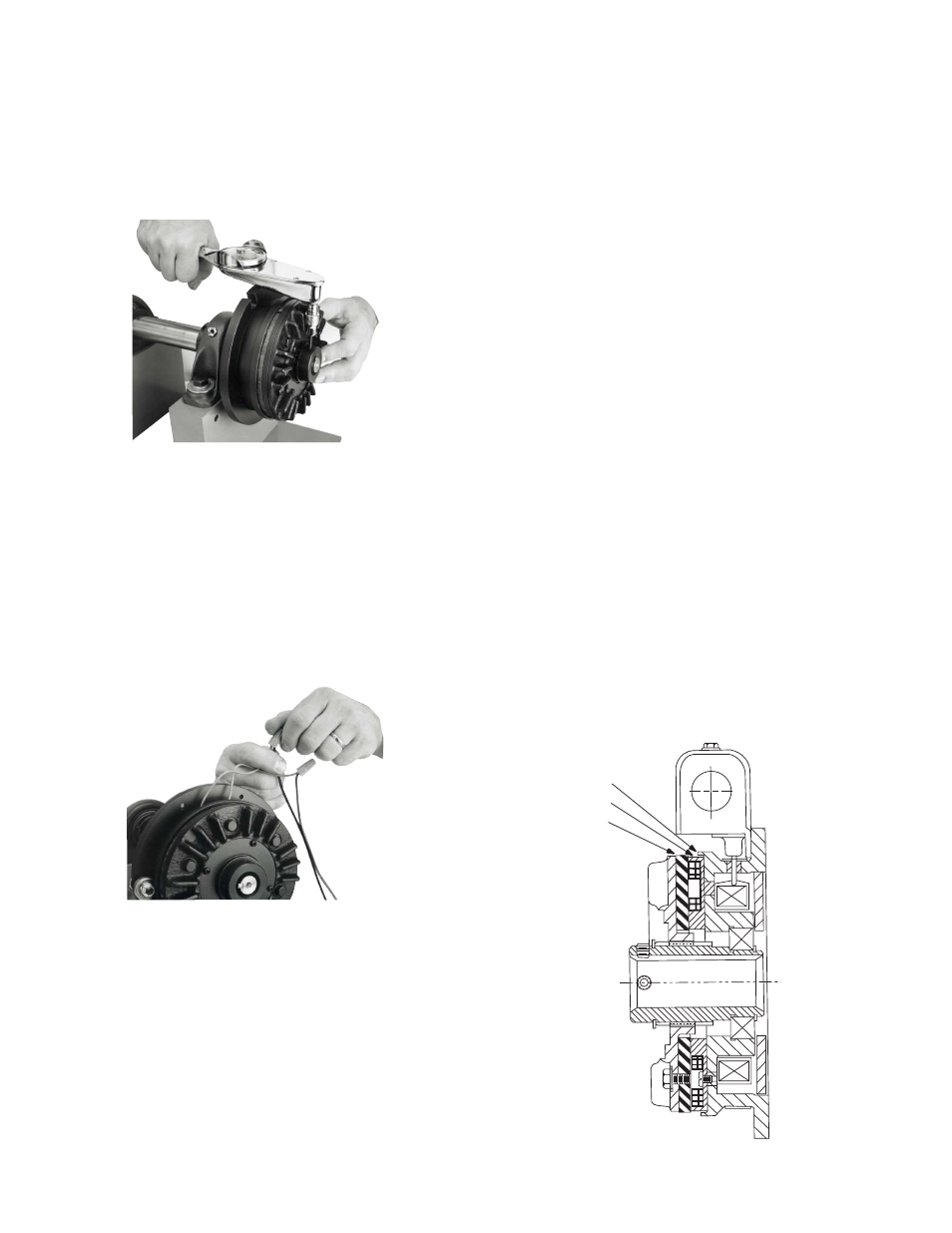

Wear Indication

Your AT brake should be visually inspected on a

periodic basis to determine if the wearing sur-

faces warrant replacement. The friction face and

armature should be replaced when the armature

reaches the wear indicator on the magnet shell.

If replacement is not made at this time, further

use will wear into the screw heads, making

removal and replacement of the friction facing

difficult. The drawing below illustrates the area

to be inspected.

When the friction surfaces are worn to this

point, replace with the appropriate friction face

replacement kit. All of the components needed

to refurbish the wearing surfaces of your brake

are provided in the replacement kit.

6. Tighten the set screws located in the hub to

the appropriate torque for your size unit:

Size

Torque

25

80 in.-lbs.

55

160 in.-lbs.

115

275 in.-lbs.

7. Attach the wires to the DC power source,

using wire nuts or other approved connecting

devices. Either wire can be connected to the

+ or - of the voltage source. If a Warner

Electric CBC-100 or other Warner Electric

control is used as the power source, follow

the connection diagram supplied with the

control. Assure that the voltage rating of the

brake is the same as the output rating of the

power source.

8. Your AT brake is now ready for its static test.

Apply DC voltage to the coil through the

brake control. The armature should pull

against the friction material face with an audi-

ble click.

9. Run the brake under its operating load.

Friction Face

Wear Indicator

Armature