Warner Electric AT Brakes & Clutches Complete Brake Repair – On the Shaft, Sizes 25, 55, 115 User Manual

Page 2

2

Warner Electric •

800-825-9050

P-1406 • 819-0335

Contents

Brake Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Warranty. . . . . . . . . . . . . . . . . . . . . . . back cover

Failure to follow these

instructions may result in product damage,

equipment damage, and serious or fatal

injury to personnel.

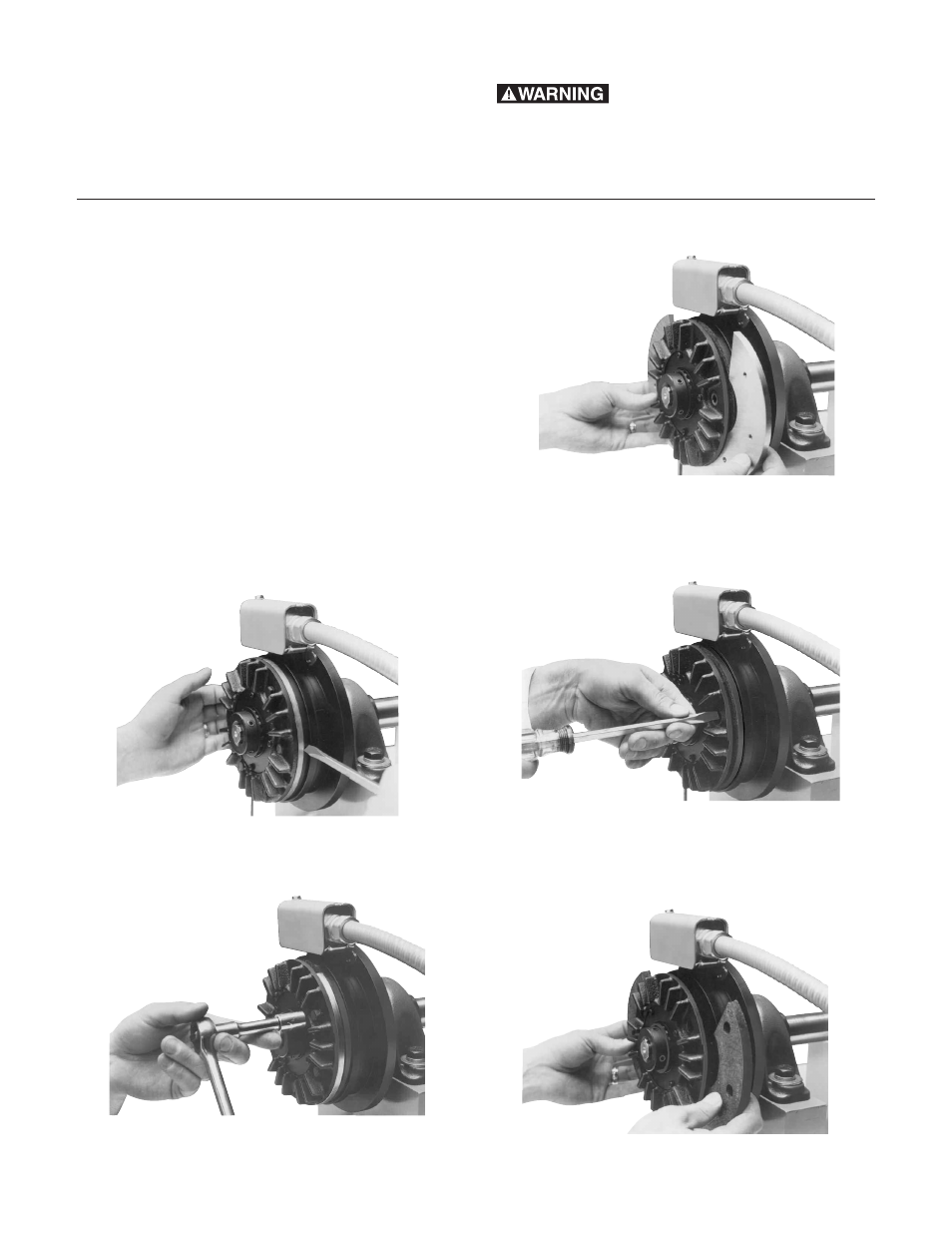

Complete Brake Repair - On the Shaft

The new AT design incorporates the latest in

advanced technology providing a rugged,

durable, patented design for long life, high cycle

rates and maximum heat dissipation. Patented,

easy to replace, friction surfaces extend the

design life for continued like-new performance.

The AT offers complete repair on the shaft

following ten easy steps. The repair can be

completed utilizing the parts in the friction face

replacement kit. The unit shown is a brake, but

steps apply equally to clutch repair.

1.

Move the brake or clutch armature away

from the magnet or field for disassembly

and reassembly.

2.

Remove hex head capscrews, washers

and lock washers to loosen the armature

segments from the cast iron carrier.

3.

Lift out the two worn armature segments.

4.

Remove the screws that attach the friction

material segments to the brake magnet or

clutch rotor through the appropriate access

holes.

5.

Lift out the worn friction material segments.

Assure that the autogap plate, detent ring

and spring remain in place on the clutch

units during this step.