Installation – Vestil ACH-100 User Manual

Page 8

3

UNPACKING

After opening the carton, carefully inspect the hoist frame,

control tube, hooks and pendant throttle control for damage

that may have occurred during shipment. If there is

damage, refer to the packing slip envelope.

All hoists are completely assembled, lubricated and load

tested prior to shipment. To place the hoist in service,

attach the upper hook to a support or trolley that has

sufficient strength to support the hoist and several times

the rated capacity of the hoist. If in doubt, consult a

registered engineer and local building code.

Be certain that the upper hook is attached to the support

so that the support is firmly seated in the center of hook

bowl, the latch closes and contacts the tip of the hook, and

that the latch does not bear against the support.

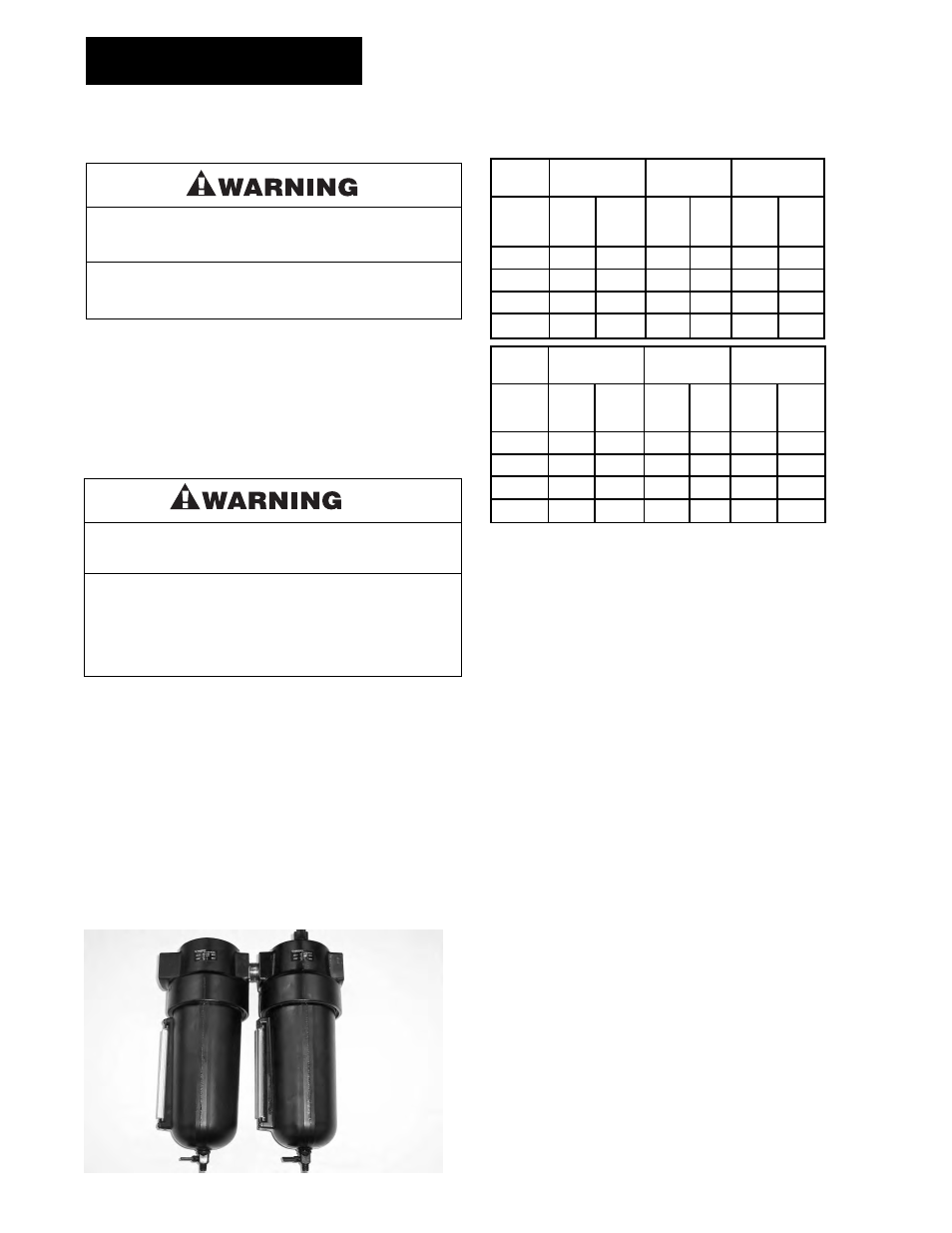

AIR SUPPLY SYSTEM

Connect hoist to a filtered and lubricated air source using a

1/2” (12.7 mm.) I.D. hose (see Figure 3). Do not use

smaller diameter hose, since it will restrict air flow and

reduce hoist performance. If the hoist is suspended from a

trolley, provide sufficient hose to reach from the source to

the farthest point of trolley travel. CM

®

Hose Trolleys are

recommended to keep the hose up and out of the way.

A filter and lubricator (see Figure 3) m

mu

us

stt be installed

between the air source and the air hose leading to the hoist.

These keep the air flowing free from dirt and add lubricant

to the air so internal parts of the motor are constantly

lubricated. Use a good grade of oil with a viscosity of 180

SSU at 100

0

F., air powered tool oil or SAE 0W machine oil.

The recommended operating air pressure for the hoist is 90

psig. When line pressure exceeds 100 psig (at the hoist

when it is lifting rated load), it is recommended that a

pressure regulator be provided in the air supply line to keep

the pressure at 90 psig. Although there is a wide range of

pressures within which the hoist will operate, motor efficiency

decreases as the air pressure drops (refer to the following

Chart).

On the (500, 600 and 1000, (226, 272 and 453 Kg.), Double

Reeved units), cut and discard the ties used to hold the two

strands of chain together. With no load on the lower hook,

depress the UP ( ) lever in the pendant throttle control and

raise the lower hook until it is about 2 feet (0.61 M) below the

bottom of the hoist. Check both strands of chains for twists.

Twists occur if the lower hook block has been capsized

between the strands of chain during packing, shipment

and/or handling. Reverse the capsize to remove twists.

CHAIN CONTAINER

If the chain container is to be used, attach it to the hoist

per the instructions provided.

OPERATING INSTRUCTIONS

The hoist is equipped with a Protector™ that is designed to

allow the first gear to slip when it is attempted to lift an

excessive overload. An overload is indicated when the

hoist speed slows down, it raises the load in a jerky

manner or if it will not lift the load at all. In addition, some

clutching noise may be heard. Should this occur,

immediately release the UP ( ) lever to stop the operation

of the hoist and reduce the load to the rated capacity of

the hoist. When the excessive load is removed, normal

operation of the hoist is automatically restored.

C

CA

AU

UT

TIIO

ON

N:: T

Th

he

e P

Prro

otte

ec

ctto

orr™

™ iis

s s

su

us

sc

ce

ep

pttiib

blle

e tto

o o

ov

ve

errh

he

ea

attiin

ng

g

a

an

nd

d w

we

ea

arr w

wh

he

en

n s

slliip

pp

pe

ed

d ffo

orr e

ex

xtte

en

nd

de

ed

d p

pe

erriio

od

ds

s.. U

Un

nd

de

err n

no

o

c

ciirrc

cu

um

ms

stta

an

nc

ce

es

s s

sh

ho

ou

ulld

d tth

he

e P

Prro

otte

ec

ctto

orr™

™ b

be

e a

allllo

ow

we

ed

d tto

o s

slliip

p ffo

orr

m

mo

orre

e tth

ha

an

n a

a ffe

ew

w s

se

ec

co

on

nd

ds

s..

Due to the above, the hoist is not recommended for use in

any application where there is a possibility of adding to an

already suspended load to the point of overload. This

includes dumbwaiter installations, containers that are loaded

in mid-air, etc. Also, if the hoist is used at unusual extremes

of ambient temperatures (above 150

0

F., 65

0

C., or below

15

0

F., -9

0

C.), changes in lubricant properties may permit

the hoist to raise larger loads than under operating

temperatures and could present possibility of property

damage or injury. Hoist operation is controlled by

depressing the pendant throttle control levers. Depressing

the UP ( ) lever will move the lower hook towards the hoist

and depressing the DOWN ( ) lever will move the lower

hook away from the hoist. The speed of lifting and lowering

can be varied by the distance the lever is depressed. To

stop lifting and lowering, release the lever. The up and down

levers are momentary type and the hoist will operate in the

selected direction as long as the lever is held in the

depressed direction. Release the lever and the hoist will

stop.

Operating the hoist with obvious external damage may

cause load to drop and that may result in personal injury

and/or property damage.

TO AVOID INJURY:

Carefully check hoist for external damage prior to

installation.

Suspending the hoist from an inadequate support may

allow the hoist and load to fall and cause injury and/or

property damage.

TO AVOID INJURY:

Make sure the structure has sufficient strength to hold

several times the hoist and its rated load. Using the

upper hook, hang the hoist from the support. B

Be

e s

su

urre

e tth

he

e

h

ho

oiis

stt iis

s s

so

olliid

dlly

y h

he

elld

d iin

n tth

he

e u

up

pp

pe

errm

mo

os

stt p

pa

arrtt o

off tth

he

e h

ho

oo

ok

k a

arrc

c

a

an

nd

d tth

he

e lla

attc

ch

h iis

s ttiig

gh

httlly

y a

ag

ga

aiin

ns

stt tth

he

e ttiip

p o

off tth

he

e h

ho

oo

ok

k..

INSTALLATION

Figure 3 Air Filter and Lubricator Unit

H

Ho

oiis

stt

C

Ca

ap

pa

ac

ciitty

y

2

25

50

0 llb

bs

s..

((1

11

13

3 K

Kg

g..))

((S

Siin

ng

glle

e R

Re

ee

ev

ve

ed

d))

3

30

00

0 llb

bs

s..

((1

13

36

6 K

Kg

g..))

((S

Siin

ng

glle

e R

Re

ee

ev

ve

ed

d))

5

50

00

0 llb

bs

s..

((2

22

26

6 K

Kg

g..))

((S

Siin

ng

glle

e R

Re

ee

ev

ve

ed

d))

Air

Pressure

(PSIG)

Up

FPM

(MPM)

Down

FPM

(MPM)

Max.

Up

FPM

(MPM)

Down

FPM

(MPM)

Max.

Up

FPM

(MPM)

Down

FPM

(MPM)

Max.

60

22

(6.7)

46.2

(14.1)

19.1

(5.8)

40.1

(12.2)

11.1

(3.4)

41.6

(12.7)

70

27.2

(8.3)

57.1

(17.4)

23.9

(7.3)

50.2

(15.3)

14.8

(4.5)

53.7

(16.4)

80

29.6

(9.0)

62.2

(19.0)

26.7

(8.1)

56.1

(17.1)

17.3

(5.3)

57.1

(17.4)

90

32.5

(9.9)

68.3

(20.8)

29.6

(9.0)

62.2

(19.0)

19.5

(5.9)

56.6

(17.3)

H

Ho

oiis

stt

C

Ca

ap

pa

ac

ciitty

y

5

50

00

0 llb

bs

s..

((2

22

26

6 K

Kg

g..))

((D

Do

ou

ub

blle

e R

Re

ee

ev

ve

ed

d))

6

60

00

0 llb

bs

s..

((2

27

72

2 K

Kg

g..))

((D

Do

ou

ub

blle

e R

Re

ee

ev

ve

ed

d))

1

10

00

00

0 llb

bs

s..

((4

45

53

3 K

Kg

g..))

((D

Do

ou

ub

blle

e R

Re

ee

ev

ve

ed

d))

Air

Pressure

(PSIG)

Up

FPM

(MPM)

Down

FPM

(MPM)

Max.

Up

FPM

(MPM)

Down

FPM

(MPM)

Max.

Up

FPM

(MPM)

Down

FPM

(MPM)

Max.

60

11

(3.4)

35.2

(10.7)

9.6

(3.0)

30.7

(9.4)

5.6

(1.7)

20.8

(6.3)

70

13.6

(4.1)

43.5

(13.3)

12

(3.7)

38.4

(11.7)

7.4

(2.3)

26.9

(8.2)

80

14.8

(4.5)

47.4

(14.4)

13.4

(4.1)

42.9

(13.1)

8.7

(2.7)

28.6

(8.7)

90

16.3

(5.0)

52.2

(15.9)

14.8

(4.5)

47.4

(14.4)

9.8

(3.0)

28.3

(8.6)