Warning, Disassembly-assembly – Vestil ACH-100 User Manual

Page 13

8

When disassembling and assembling the ShopAir Hoist,

refer to the exploded view and the parts list on pages 10

thru 14. These show the proper relationship of the parts,

the names of the parts and the required quantities of the

parts. In addition, please observe the following:

1.

Needle bearings are pressed into the gear housing

(620-113), main frame (620-107), liftwheel (620-127)

and lower sheave wheel (620-162). Unless they are to

be replaced, do not attempt to remove these bearings.

2.

A liftwheel seal (620-108) is pressed into the main frame

(620-107) and a seal (620-130) is pressed into the end

of the liftwheel shaft (620-148). Be careful that these

seals are not cut or damaged during disassembly and

reassembly.

3.

Refer to page 7 for disassembly, inspection and

reassembly of the brake.

4.

Do not attempt to disassemble the Protector™ - refer to

page 7.

5.

Refer to page 6 for lubrication instructions.

6.

See next section for load chain removal and installation.

7.

Tighten the various screws as follows:

KEY-NO.

PART NAME

SEATING TORQUE

LB. IN.

NM

620-126

Pin Retainer Plate Screw

25

2.8

620-154

Motor Cover Screw

25

2.8

620-134

Gear Housing Screw

25

2.8

620-133

Brake End Cover Screw

25

2.8

620-168

Dead End Plate Screw

125

14.1

620-140

Hook Retainer Screw

10

1.1

620-157

Hook Block Screw

500, 600 and 1000 lbs.

(226, 272 and 453 Kg.)

(Double Reeved) units

125

14.1

250, 300 and 500 lbs.

(113, 136 and 226 Kg.)

(Single Reeved) units

50

5.6

620-510

Motor Screws

25

2.8

620-517

Valve Block Screws

25

2.8

620-518

Supply Bolt

50

5.6

8.

To remove the air motor (620-538), remove the motor

end cover (620-502) and motor end spacer (620-528).

Loose the valve bolts (620-518) enough to remove the

valve block assembly from the bottom of the motor.

Remove the two screws used to attach the motor to the

main frame (620-107) and carefully slide the motor shaft

out of the coupling (620-508). If necessary, refer to

page 9 for instructions for disassembling the motor.

9.

To install the air motor (620-538), slide the coupling (650-

508) onto the end of the motor shaft. Align splines on the

first pinion and shaft (620-131) and coupling and then

slide the motor into position. Secure the motor to the main

frame (620-107) using two screws. Attach the valve

assembly to the bottom of the motor using the two valve

bolts (620-518), making sure the O-rings are on the valve

bolts. Assemble the motor end spacer (620-528) and

motor end cover (620-502) to the main frame using three

screws.

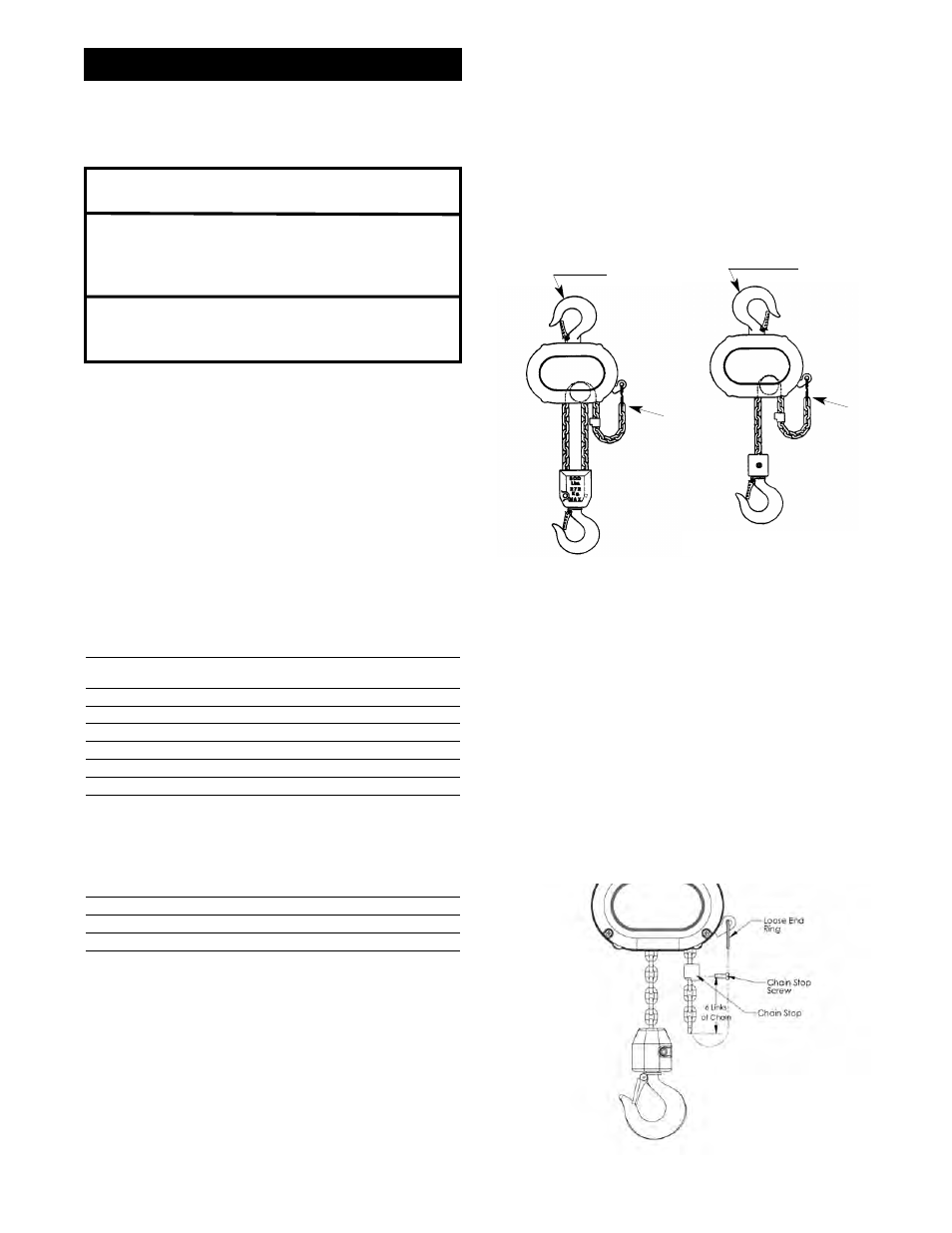

10. Properly install the upper hook as shown in Figure 11A,

then slide the hook retainer (620-139) into the cavity on

top of the hoist and secure it using hook retainer screw

(620-140). Tighten screw to a seating torque of 10 in. lbs.

(1.1 NM).

11. After reassembly, test the unit per instructions on page 9.

LOAD CHAIN REMOVAL/INSTALLATION

1.

If unit has a chain container, remove it from the chain

guide.

2.

Remove the chain stop (620-146), Depress “DOWN” ( )

lever and run chain out of hoist.

3.

Feed a short length of soft wire through the opening

between the chain guide (620-141), and stripper (620-143)

until it comes out of the hoist. Remove the wire and attach

the chain stop as shown below. On units with chain

container, place the chain stop and loose end of chain in

chain container. Attach chain container to chain guide.

4.

Jog the “UP” ( ) lever while pulling on the free end of wire

until the chain comes out of the hoist. Remove the wire

and attach the chain stop as shown below. On units with

chain container, place chain stop and loose end of chain

in chain container. Attach chain container to chain guide.

DISASSEMBLY-ASSEMBLY

F

Fiig

gu

urre

e 1

12

2.. A

Atttta

ac

ch

hiin

ng

g L

Lo

oo

os

se

e E

En

nd

d o

off C

Ch

ha

aiin

n

ShopAir

ShopAir

Hook Opening

Away From

Loose End

Hook

Opening

Towards

Loose End

Loose

End

Loose

End

F

Fiig

gu

urre

e 1

11

1.. H

Ho

oo

ok

k P

Po

os

siittiio

on

n

L

!

WARNING

Components such as motors, valves, lines,

filter/lubricators located after a closed shut-

off valve can contain pressurized air.

Disassembly in this state can cause injury.

Bleed the stored air by repeatedly

depressing the pendant paddles.