Vestil ACH-100 User Manual

Page 10

LOAD CHAIN

Chain should feed smoothly into and away from the hoist

or hook block (500, 600 and 1000#, 226, 272 and 453 Kg.

units). If chain binds, jumps or is noisy, first clean and

lubricate it (see below). If trouble persists, inspect chain

and mating parts for wear, distortion or other damage.

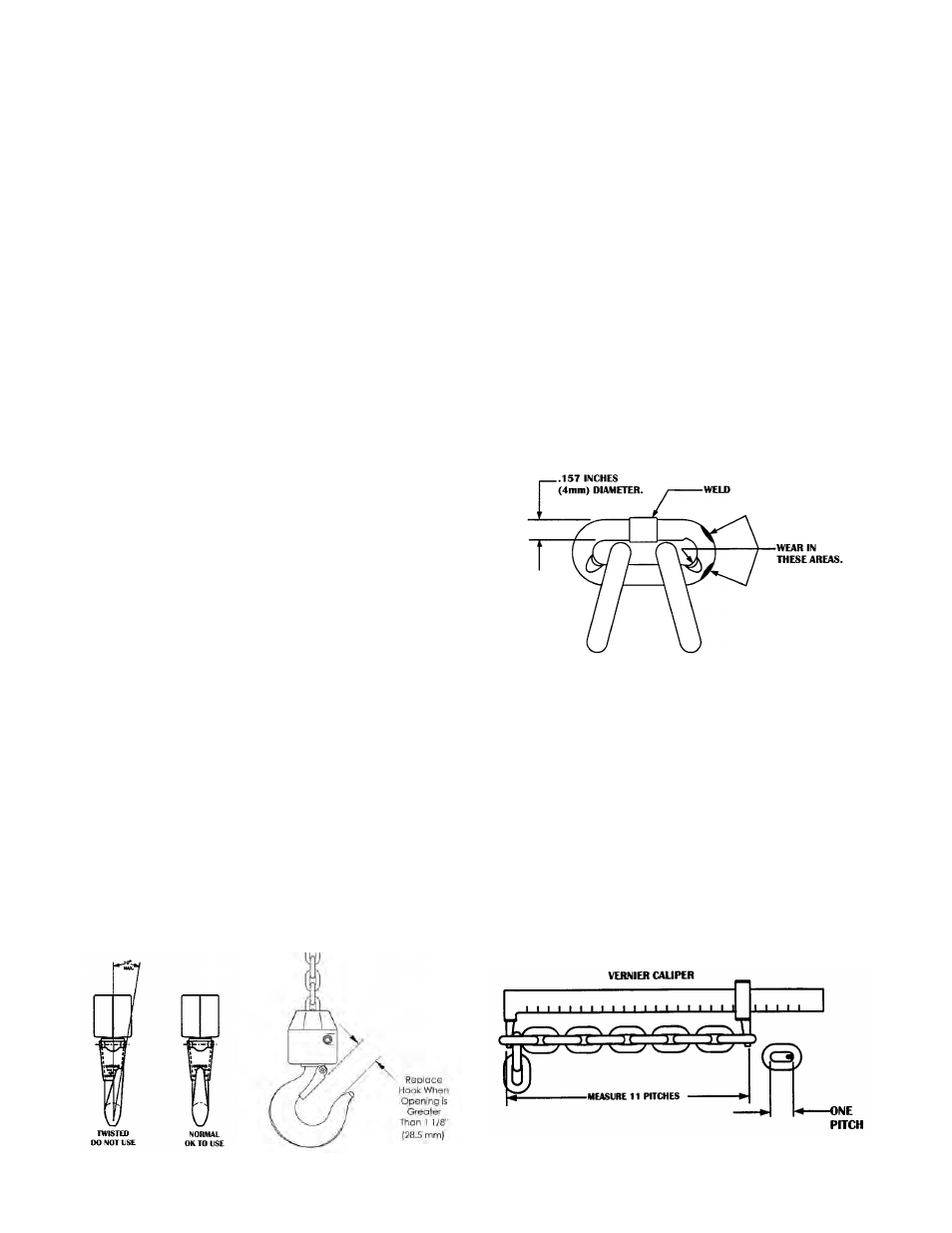

Chain Inspection

First clean chain with a non-caustic/non-acid type solvent

and make a link by link inspection for nicks, gouges,

twisted links, weld spatter, corrosion pits, sitriations

(minute parallel lines), cracks in weld areas, wear and

stretching. Chain with any one of these defects must be

replaced.

Slack the portion of the chain that normally passes over

the liftwheel. Examine the interlink area for the point of

maximum wear (polishing, see figure 5). Measure and

record the stock diameter at this point of the link. Then

measure stock diameter in the same area on a link that

does not pass over the liftwheel (use the link adjacent to

the loose end link for this purpose). Compare these two

measurements. If the stock diameter of the worn link is

0.010 inches (0.254 mm.), or more, less than the stock

diameter of the unworn link, the chain must be replaced.

On the 500, 600 and 1000# (226, 272 and 453 Kg.) units,

repeat this examination of the chain that passes through the

hook block.

Also check chain for stretch using a vernier caliper as

shown in figure 6. Select an unused, unstretched section

of chain (usually at the loose end) and measure and

record the length over 11 chain links (pitches). Measure

and record the same length on a worn section of chain.

Obtain the amount of stretch and wear by subtracting the

measurement of the unworn section from the measurement

of the worn section. If the result (amount of stretch and

wear) is greater than 0.145 inch (3.7 mm.), the chain must

be replaced.

Use only a “Knife-edge” caliper to eliminate possibility of

false reading by not measuring full pitch length.

5

e. External evidence of excessive wear of brake parts -

see page 7.

f.

Check the control station levers to make sure they

operate freely and spring back when released.

g. Check air supply hose and control hose for kinks, cuts,

leaks and damage.

h. Check the chain pin or dead end pin and chain stop

for wear and cracks.

i.

Check for lubricant leaks at gasket between main

frame and gear housing. Tighten gear housing screws

to stop leak. If leak persists, replace gasket.

j.

Inspect splines on first pinion shaft and motor coupling

for signs of wear or deterioration. Replace splined

parts if worn or damaged.

k. Check for air leaks at brake end cap. Replace piston

seals to stop leaks.

l.

Check for air leaks at the joints of the motor. Tighten

screws to stop leaks. If leaks persist, disassemble

motor, see page 8, and replace seals.

m. Check for air leaks at joint between the supply block

and valve body. Tighten screws or replace gasket to

stop leaks.

n. Check for air leaks at o-rings on top and under valve

body. Tighten valve bolt or replace o-ring to stop leaks.

N

NO

OT

TE

E:: T

To

o p

pe

errffo

orrm

m s

so

om

me

e o

off tth

he

e p

pe

erriio

od

diic

c iin

ns

sp

pe

ec

cttiio

on

ns

s,, iitt iis

s

n

ne

ec

ce

es

ss

sa

arry

y tto

o p

pa

arrttiia

alllly

y d

diis

sa

as

ss

se

em

mb

blle

e tth

he

e h

ho

oiis

stt.. R

Re

effe

err tto

o

D

Diis

sa

as

ss

se

em

mb

blly

y--A

As

ss

se

em

mb

blly

y s

stta

arrttiin

ng

g o

on

n p

pa

ag

ge

e 8

8..

Any deficiencies noted must be corrected before the hoist

is returned to service. Also, the external conditions may

show the need for more detailed inspection which, in turn,

may require the use of nondestructive-type testing.

Any parts that are deemed unserviceable are to be

replaced with new parts before the unit is returned to

service. It is very important that the unserviceable parts

be destroyed to prevent possible future use as a repair

item and properly disposed of.

Hook Inspection

Hook damage from chemicals, deformations or cracks or

that have more than a 10

0

twist from the plane of the

unbent hook or excessive opening must be replaced.

Any hook that is twisted or has excessive throat opening

indicates abuse or overloading of the unit. Other load-

sustaining components of the hoist should be inspected

for damage.

On latch type hooks, check to make sure that the latch is

not damaged or bent and that it operates properly with

sufficient spring pressure to keep the latch tightly against

the tip of the hook and allow the latch to spring back to

the tip when released. See below to determine when the

hook must be replaced.

F

Fiig

gu

urre

e 4

4.. H

Ho

oo

ok

k IIn

ns

sp

pe

ec

cttiio

on

n

F

Fiig

gu

urre

e 5

5.. C

Ch

ha

aiin

n W

We

ea

arr A

Arre

ea

as

s

F

Fiig

gu

urre

e 6

6.. C

Ch

ha

aiin

n IIn

ns

sp

pe

ec

cttiio

on

n