Vestil ACH-100 User Manual

Page 11

Note that worn chain can be an indication of worn hoist

components. For this reason, the hoist’s chain guide, hook

block and liftwheel should be examined for wear and

replaced as necessary when replacing worn chain.

Also, these chains are specially heat treated and hardened

and should never be repaired.

IIM

MP

PO

OR

RT

TA

AN

NT

T:: D

Do

o n

no

ott u

us

se

e rre

ep

plla

ac

ce

ed

d c

ch

ha

aiin

n ffo

orr o

otth

he

err p

pu

urrp

po

os

se

es

s

s

su

uc

ch

h a

as

s lliiffttiin

ng

g o

orr p

pu

ulllliin

ng

g.. L

Lo

oa

ad

d c

ch

ha

aiin

n m

ma

ay

y b

brre

ea

ak

k s

su

ud

dd

de

en

nlly

y

w

wiitth

ho

ou

utt v

viis

su

ua

all d

de

effo

orrm

mttiio

on

n.. F

Fo

orr tth

hiis

s rre

ea

as

so

on

n,, c

cu

utt rre

ep

plla

ac

ce

ed

d

c

ch

ha

aiin

n iin

ntto

o s

sh

ho

orrtt lle

en

ng

gtth

hs

s tto

o p

prre

ev

ve

en

ntt u

us

se

e a

afftte

err d

diis

sp

po

os

sa

all..

Chain Lubrication

A small amount of lubricant will greatly increase the life of

load chain. Do not allow the chain to run dry. keep it clean

and lubricate at regular intervals with Lubriplate

®

Bar and

Chain Oil 10-R (Fiske Bros, Refining Co.) or equal lubricant.

Normally, weekly lubrication and cleaning is satisfactory, but

under hot and dirty conditions, it may be necessary to clean

the chain at least once a day and lubricate it several times

between cleanings.

When lubricating the chain, apply sufficient lubricant to

obtain natural run-off and full coverage, especially in the

interlink area.

LUBRICATION

Refer to Exploded View and Parts List on pages 10 thru 14.

N

NO

OT

TE

E:: T

To

o a

as

ss

su

urre

e e

ex

xttrra

a llo

on

ng

g lliiffe

e a

an

nd

d tto

op

p p

pe

errffo

orrm

ma

an

nc

ce

e,, b

be

e

s

su

urre

e tto

o llu

ub

brriic

ca

atte

e tth

he

e v

va

arriio

ou

us

s p

pa

arrtts

s o

off tth

he

e S

Sh

ho

op

pA

Aiirr H

Ho

oiis

stt

u

us

siin

ng

g tth

he

e llu

ub

brriic

ca

an

ntts

s s

sp

pe

ec

ciiffiie

ed

d b

be

ello

ow

w.. IIff d

de

es

siirre

ed

d,, tth

he

es

se

e

llu

ub

brriic

ca

an

ntts

s m

ma

ay

y b

be

e p

pu

urrc

ch

ha

as

se

ed

d ffrro

om

m C

CM

M

®

®

.. R

Re

effe

err tto

o p

pa

ag

ge

e 1

11

1

ffo

orr iin

nffo

orrm

ma

attiio

on

n o

on

n o

orrd

de

erriin

ng

g tth

he

e llu

ub

brriic

ca

an

ntts

s..

6

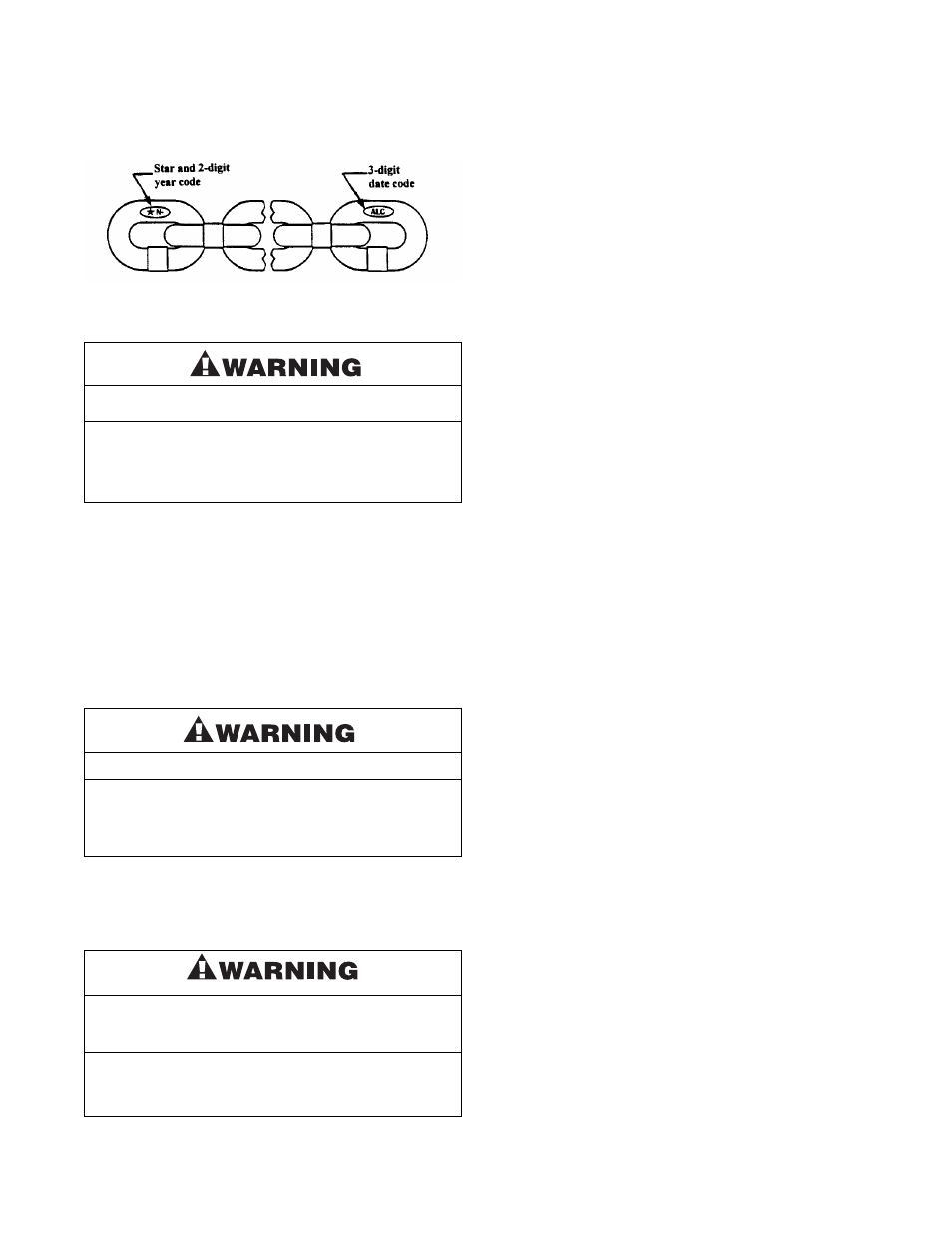

Use of commercial or other manufactures’ chain and parts

to repair ShopAir Hoists may cause load loss.

TO AVOID INJURY:

Use only factory supplied replacement load chain and

parts. Chain and parts may look alike, but factory original

chain and parts are made of specific materials or processed

to achieve specific properties. See Figure 7.

Used motor oils contain known carcinogenic materials.

TO AVOID HEALTH PROBLEMS:

Never use used motor oils as a chain lubricant. Only use

Lubriplate

®

Bar and Chain Oil 10-R as a lubricant for the

load chain.

The lubricants used in and recommended for the ShopAir

Hoist may contain hazardous materials that mandate

specific handling and disposal procedures.

TO AVOID CONTACT AND CONTAMINATION:

Handle and dispose of lubricants only as directed in

applicable material safety data sheets and in accordance

with applicable local, state and federal regulations.

Gears

The Protector™ (620-111) should operate for the normal life of

the hoist without service. The device has been lubricated and

calibrated by CM

®

and should not be adjusted.

C

CA

AU

UT

TIIO

ON

N:: T

Th

he

e P

Prro

otte

ec

ctto

orr™

™ iis

s tto

o b

be

e u

us

se

ed

d w

wiitth

h ““C

Ce

en

nttu

urry

y

L

Lu

ub

brriic

ca

an

ntts

s H

HB

B--1

11

1,, #

#3

3”” g

grre

ea

as

se

e.. D

Do

o n

no

ott u

us

se

e a

an

ny

y o

otth

he

err g

grre

ea

as

se

e o

orr

tth

he

e P

Prro

otte

ec

ctto

orr™

™ w

wiillll n

no

ott o

op

pe

erra

atte

e p

prro

op

pe

errlly

y a

an

nd

d p

pa

arrtts

s c

co

ou

ulld

d b

be

e

d

da

am

ma

ag

ge

ed

d..

The gears and Protector™ are packed at assembly with

grease and should not need to be renewed unless the gears

have been removed from the housing and degreased.

C

CA

AU

UT

TIIO

ON

N:: N

Ne

ev

ve

err d

de

eg

grre

ea

as

se

e tth

he

e P

Prro

otte

ec

ctto

orr™

™ o

orr a

atttte

em

mp

ptt tto

o

d

diis

sa

as

ss

se

em

mb

blle

e tth

hiis

s d

de

ev

viic

ce

e.. D

De

eg

grre

ea

as

siin

ng

g tth

he

e P

Prro

otte

ec

ctto

orr™

™ m

ma

ay

y

d

da

am

ma

ag

ge

e p

pa

arrtts

s a

an

nd

d u

us

siin

ng

g a

a d

de

ev

viic

ce

e tth

ha

att h

ha

as

s b

be

ee

en

n d

de

eg

grre

ea

as

se

ed

d

m

ma

ay

y c

ca

au

us

se

e e

errrra

attiic

c,, iin

nc

co

on

ns

siis

stte

en

ntt o

op

pe

erra

attiio

on

n.. IIff tth

he

e P

Prro

otte

ec

ctto

orr™

™

h

ha

as

s b

be

ee

en

n d

de

eg

grre

ea

as

se

ed

d,, iitt m

mu

us

stt b

be

e rre

ep

plla

ac

ce

ed

d b

by

y a

a C

CM

M

®

®

c

ca

alliib

brra

atte

ed

d

d

de

ev

viic

ce

e..

If the gears are removed from the housing, wipe the excess

grease off the outside surfaces of the Protector™ with a soft

cloth and degrease the remaining gears and housings. Upon

reassembly, add 2 oz. of the above grease to gears and

housing. Also, coat the spline on the end of the first pinion

and shaft (620-131) with a Molydisulphide lubricant such as

Moly-Duolube 67 (Hercules Packing Co.).

Bearings

Needle bearings (620-109, 620-114, 620-115, 620-128 and

620-164) are packed at assembly with grease and should

not need to be relubricated. However, if the housings (620-

113 and 620-107), liftwheel (620-127) or sheave wheel (620-

162) have been degreased, these bearings should be

greased using “Century Lubricants HB-11, #3” grease.

Seals

When reassembling the unit, wipe the inside surface of the

seals with “Century Lubricants HB-11, #3” grease.

Service Air Line Lubricator

The air line filter and lubricator is the only source of lubrication

for control valves and air motor. Fill lubricator with a good

grade air hoist motor oil or low machine oil (viscosity of 180

SSU at 100

0

F.). Multi-viscosity, detergent type oil is not

recommended. Feed one drop of oil for every 50 to 75 cubic

feet of air going through the air motor.

Hook Block

If the hook blocks are disassembled for inspection purposes,

wipe the grease from the hook knob and the hook knob

cavities in the hook blocks. At reassembly, coat the underside

of the hook knob and the knob bearing surfaces of cavities in

the hook blocks with Molykote BR-2-S (Dow Corning Corp.)

grease or equivalent.

Chain Guide, Liftwheel and Sheave Wheel

When the hoist is disassembled for inspection and/or repair, the

chain guide, stripper, sheave wheel (on double chain unit) and

liftwheel must be lubricated with Lubriplate

®

Bar and Chain Oil

10-R (Fiske Bros. Refining Co.) prior to reassembly. The

lubricant must be applied in sufficient quantity to obtain natural

runoff and full coverage of these parts.

L

Lo

oa

ad

d C

Ch

ha

aiin

n

See above for lubrication of the load chain.

Exterior Finish

The exterior surface of the hoist has a durable, scratch

resistant baked powder coating. Normally, the exterior

surfaces can be cleaned by wiping with a cloth.

F

Fiig

gu

urre

e 7

7.. C

Ch

ha

aiin

n E

Em

mb

bo

os

ss

siin

ng

g

U

Us

se

e o

on

nlly

y S

Stta

arr ((**)) g

grra

ad

de

e llo

oa

ad

d c

ch

ha

aiin

n a

an

nd

d o

orriig

giin

na

all

rre

ep

plla

ac

ce

em

me

en

ntt p

pa

arrtts

s.. U

Us

se

e o

off o

otth

he

err c

ch

ha

aiin

n a

an

nd

d p

pa

arrtts

s

m

ma

ay

y b

be

e d

da

an

ng

ge

erro

ou

us

s a

an

nd

d v

vo

oiid

ds

s ffa

ac

ctto

orry

y w

wa

arrrra

an

ntty

y..