KB Electronics KBWA-23D User Manual

Page 25

25

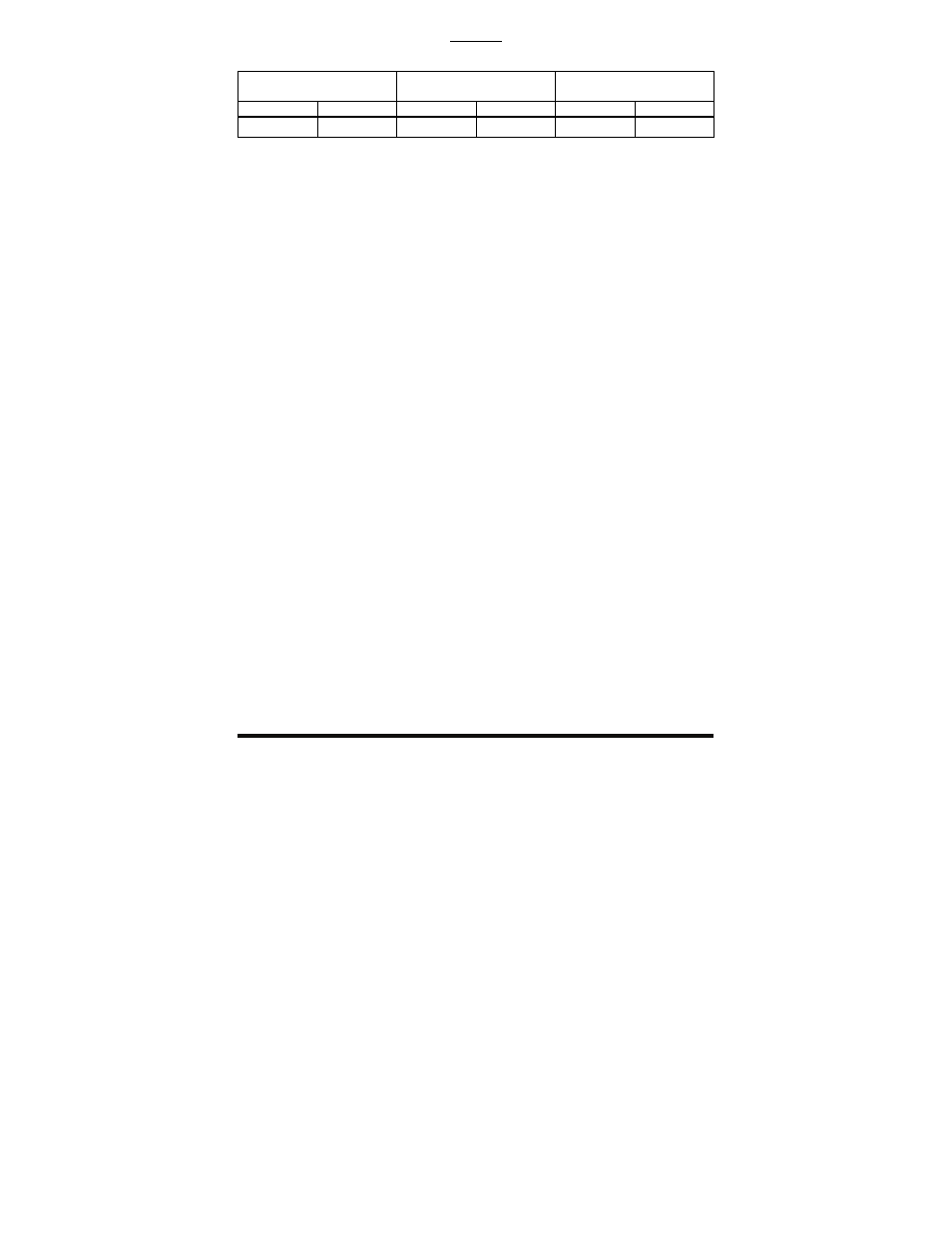

TABLE 4

TERMINAL BLOCK TB1

WIRE AND TIGHTENING TORQUE SPECIFICATIONS

Copper Wire Size Range

(Solid or Stranded*)

Stripping Length

Tightening Torque Range

AWG mm

2

in mm

in-lbs

kg-cm

30 – 14

0.05 – 2.08

0.25 6

4.4 – 5.3

5.1 – 6.1

*If using stranded wire, be sure that all strands are contained in the terminal block

housing.

10.1 AC LINE INPUT AND GROUND

Connect the single-phase AC line input to TB1 Terminals "L1" and "L2". Connect the

Ground (earth) to TB1 Terminal "GND". See Figure 15, on page 26. For 208/230 Volt

AC Line input, be sure that Jumper J3 is not installed (factory setting). For 115

Volt AC Line input, install Jumper J3 (supplied). See Section 7.1, on page 19.

Note: The actual AC Line Input voltage must correspond to the setting of Jumper J3.

For 208/230 Volt AC Line Input, be sure that Jumper J3 is not installed. For 115 Volt

AC Line input, install Jumper J3 (supplied). Applying 230 Volts to the drive set for 115

Volt AC Line input will cause catastrophic failure.

10.2 MOTOR AND GROUND

Connect the Motor to TB1 Terminals "U", "V", and "W". Connect the Ground (earth) to

TB1 Terminal "GND". See Figure 15, on page 26.

Motor cable length should not exceed 100 feet (30 m) – special reactors may be

required – consult our Sales Department.

Be sure that the Current Limit is calibrated to the actual motor nameplate current

rating. Do not exceed the drive's maximum current rating.

Note: If the motor does not rotate in the desired direction, either: 1. Reverse any two

motor leads (with the AC Line disconnected and the motor stopped). 2. Change the

setting of the F-S-R Jumper, on CON2. See Section 7.4, on page 22. 3. If the

Forward-Stop-Reverse Switch is installed, reverse the connector installed on CON2.

See Section 6, on page 18.