D. user interface display – HTP EL-399 User Manual

Page 67

67

LP- 293 REV. 5.20.14

This appliance has wire function labels on all internal wiring. Observe the position of each wire before removing it. Wiring errors may

cause improper and dangerous operation. Verify proper operation after servicing.

If overheating occurs, or the gas supply fails to shut off, do not turn off electrical power to the circulating pump. This may aggravate the

problem and increase the likelihood of boiler damage. Instead, shut off the gas supply to the boiler at the gas service valve.

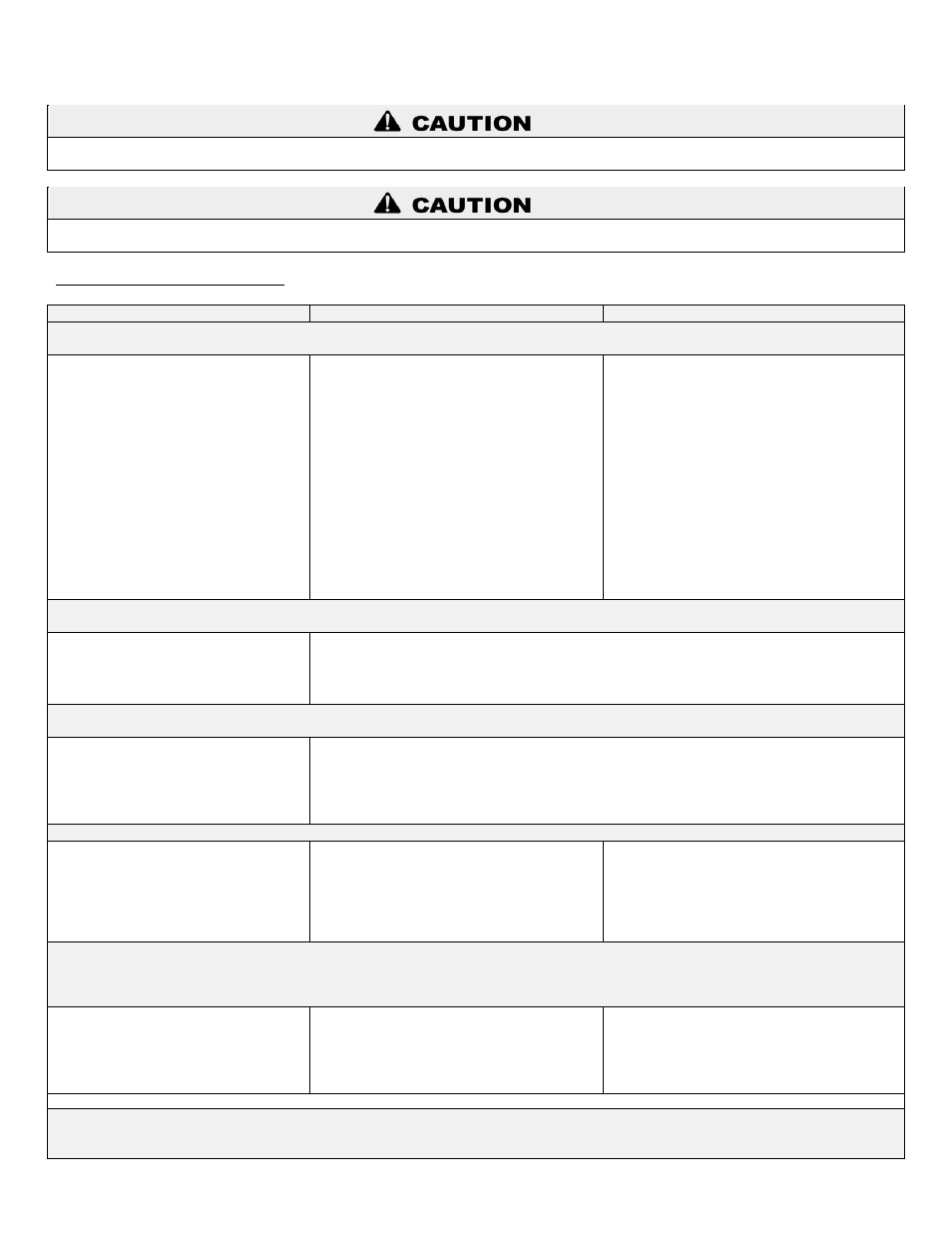

D. USER INTERFACE DISPLAY

Cascade Control FAULT Codes

SCREEN

DESCRIPTION

POSSIBLE REMEDY

Fault Code EO3

System Sensor Failure

SYS SUPPLY SENSOR

PUMP OFF E03

This screen shows that there is a problem with the

system sensor circuit. The circuit could be open or

shorted. Possible reasons for this error are:

There is no system sensor connected to the

Master Boiler.

The system sensor is faulty.

There is a short circuit in the system sensor

wiring; possibly from a staple placed through the

wire, or damage to the wire causing both

conductors to touch.

The system sensor wiring is open due to defect or

damage.

Disconnect the system sensor from the wiring and

measure the resistance of it. Compare the

measured resistance to the table in this manual to

see if it corresponds to the temperature of the

sensor. If the resistance does not agree with the

sensor, replace the sensor. If the sensor is OK,

disconnect the sensor wiring from both the boiler

and the sensor and check continuity using an

ohmmeter. Repair or replace as necessary.

If this error is present, all boilers in the cascaded

group will run and ignite simultaneously when there

is a heat demand. Each boiler will modulate to

maintain set point temperature on its own supply

sensor. This code will reset automatically when

repair is complete. This code will not display if

system setting function ERROR SYSTEM SENS is

set to OFF.

Fault Code TT

Temperature Blocking TT Demand

TEMPER BLOCKING

PUMP ON TT

This screen indicates a temporary hold on the burner. There is a demand on the boiler, the pump is

powered on, but the temperature of the water at the supply sensor is too high for the boiler to ignite. This

occurs because the water temperature measured by the supply sensor is higher than the boiler

temperature

– ignition diff setting. This error will clear itself when the water temperature measured by the

supply sensor is less than the boiler temperature

– ignition diff setting.

Fault Code DHW

Temperature Blocking DHW Demand

TEMPER BLOCKING

PUMP ON DHW

This display indicates a temporary hold on the burner. There is a demand on the boiler from the DHW

circuit for heat, the pump is powered on, but the boiler supply sensor indicates that the water

temperature is too high to ignite. This is a temporary hold on the burner only and all other functions will

remain functioning properly. This error will clear itself when either the boiler supply temperature drops

below the BOILER SUPPLY minus boiler supply differential (5

o

F) or DHW SETPOINT is satisfied and no

longer calls for heat.

Fault Code PRO

LOW WATER PRESS

PUMP OFF PRO

This display indicates that there is low water

pressure in the boiler. This code will reset

automatically after the water pressure is high

enough for the boiler to run safely. The second

line indicates the status of the pump. Note that

while the water pressure is low, the pump will be

off.

1. Assure that the system pressure is above 10

psig.

2. Check for leaks in the system piping.

Fault Code FLU

HIGH FLUE PRESS FLU

PUMP ON

This display indicates that there is excessive flue

pressure. This code resets automatically after the

high pressure condition is resolved. The second

line indicates the status of the pump.

1. Assure that the flue is not blocked.

2. Check the switch wiring by applying a jumper in

place of the switch. If the code clears with the

jumper in place, REPLACE the flue switch and

connect the wires to the new switch BEFORE

running boiler.

WARNING: Do not use jumper to remedy an FLU error. Faulty switch MUST be replaced. Failure to do so could result in serious injury or death.