Part 11, Troubleshooting, A. boiler error code – HTP EL-399 User Manual

Page 66: B. boiler error, C. boiler fault, Part 11 – troubleshooting

66

LP- 293 REV. 5.20.14

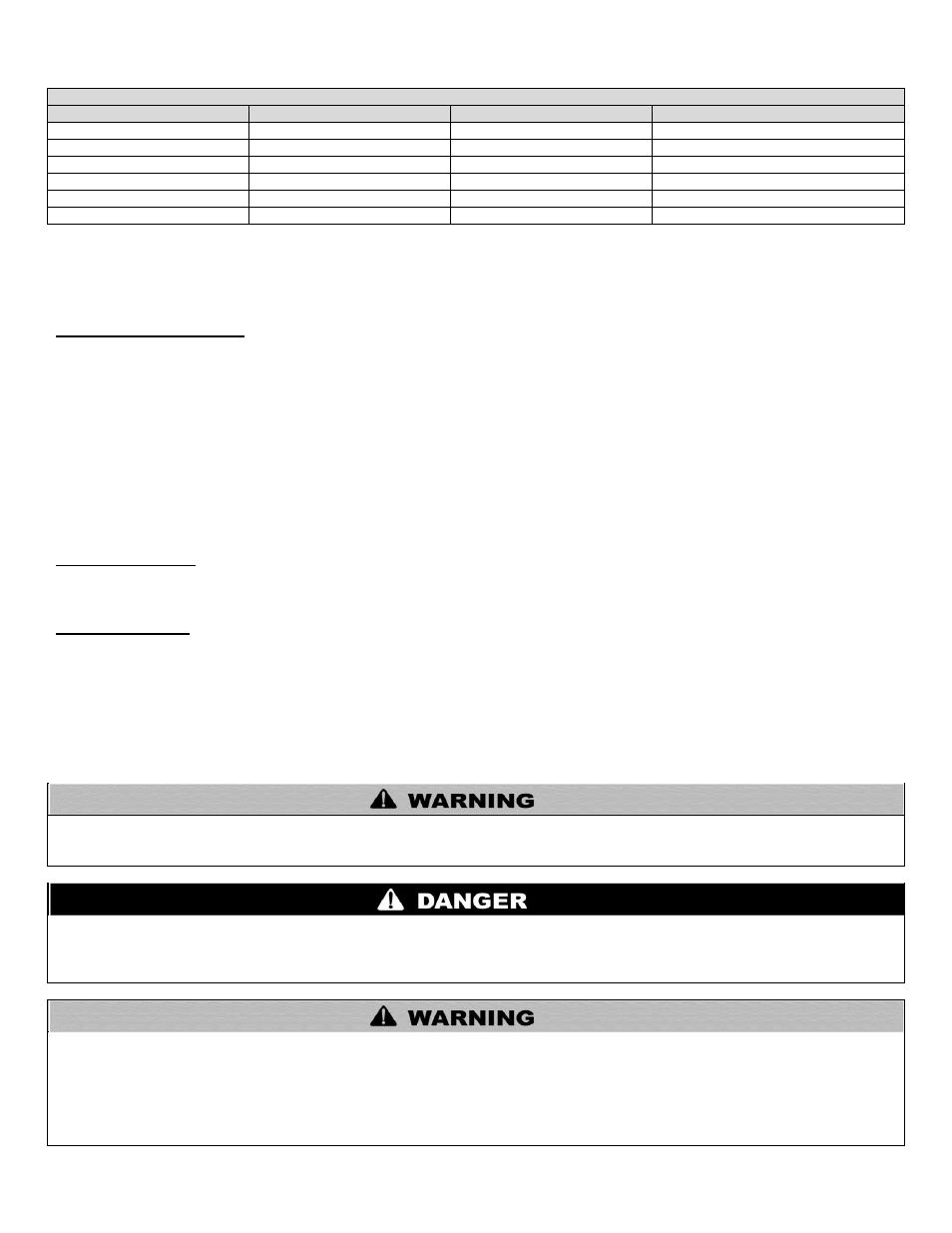

ELITE FAN SPEEDS

MODEL

IGNITION

MIN

MAX

80

3000

1700

4600

110

3800

1700

4950

150

3800

1700

5200

220

3000

1450

4900

299/301

3000

1450

5000

399

3000

1600

6650

Table 26

PART 11 – TROUBLESHOOTING

A. BOILER ERROR CODE

If any of the sensors detect an abnormal condition, or an internal component fails during the operation of the boiler, the display may

show an error message and error code. This message and code may be the result of a temporary condition, in which case the display

will revert to its normal readout when the condition is corrected, or it may be a condition that the controller has evaluated as not safe to

restart the boiler. In this case, the boiler control will be locked out, the red FAULT light will be lit, and the mes

sage “LOCKOUT” will be

displayed on the readout on the lower line.

The Boiler will not start until a qualified technician has repaired the boiler and pressed the RESET button for more than 1 second. If

there is an error message displayed on the readout, and the mes

sage “LOCKOUT” is not displayed and the FAULT light is not lit, then

the message is the result of a temporary condition and will disappear when the problem corrects itself.

IMPORTANT NOTE: If you see error messages on your display readout, call a technician immediately, since the message may indicate

a more serious problem will occur soon.

B. BOILER ERROR

When an error condition occurs, the controller will display a description and code on the display readout. These error messages and

their recommended corrective actions are described in Section D.

C. BOILER FAULT

1.

When a fault condition occurs, the controller will illuminate the red “FAULT” indication light and display a fault message in the screen.

The alarm output will also activate. Most fault conditions cause the CH pump to run in an attempt to cool the boiler.

2. Note the fault message displayed and refer to Section D in this part for an explanation of the message along with several

suggestions for corrective actions.

3. Press the reset key to clear the fault and resume operation. Be sure to observe the operation of the unit for a period of time to assure

correct operation and no reoccurrence of fault message.

When servicing or replacing any components of this boiler, be certain that:

The gas is off.

All electrical power is disconnected.

When servicing or replacing components that are in direct contact with boiler water, be certain that:

There is no pressure in the boiler. (Pull the release on the relief valve. Do not depend on the pressure gauge reading.

The boiler water is not hot.

The electrical power is disconnected.

DO NOT USE THIS APPLIANCE IF ANY PART HAS BEEN SUBMERGED IN WATER. Immediately call a qualified service technician.

The appliance MUST BE replaced if it has been submerged. Attempting to operate an appliance that has been submerged could create

numerous harmful conditions, such as a potential gas leakage causing a fire and/or explosion, or the release of mold, bacteria, or other

harmful particulates into the air. Operating a previously submerged appliance could result in property damage, severe personal injury,

or death.

NOTE: Appliance damage due to flood or submersion is considered an Act of God, and IS NOT covered under product warranty.