F. check thermostat circuit(s), G. condensate removal – HTP EL-399 User Manual

Page 56

56

LP- 293 REV. 5.20.14

a. Connect a hose to the purge valve and route hose to an area where water can drain and be seen.

b. Close the boiler or system isolation valve between the purge valve and fill connection to the system.

c. Close zone isolation valves.

d. Open quick-fill valve on cold water make-up line.

e. Open purge valve.

f. Open the isolation valves one zone at a time. Allow water to run through the zone, pushing out the air. Run water until no

noticeable air flow is present. Close the zone isolation valves and proceed with the next zone. Follow this procedure until all

zones are purged.

g. Close the quick-fill water valve and purge valve and remove the hose. Open all isolation valves. Watch the system pressure

rise to correct cold-fill pressure. It is recommended that you put the pumps into manual operation to assist in purging the

circuits.

h. Disconnect the wires that are connected to the THERMOSTAT terminals of the customer connection board. Apply power to

the boiler. The display will show the temperature of the water in the boiler. Press the

▼ and

ENTER

keys simultaneously and

hold for 1 second. The display will read:

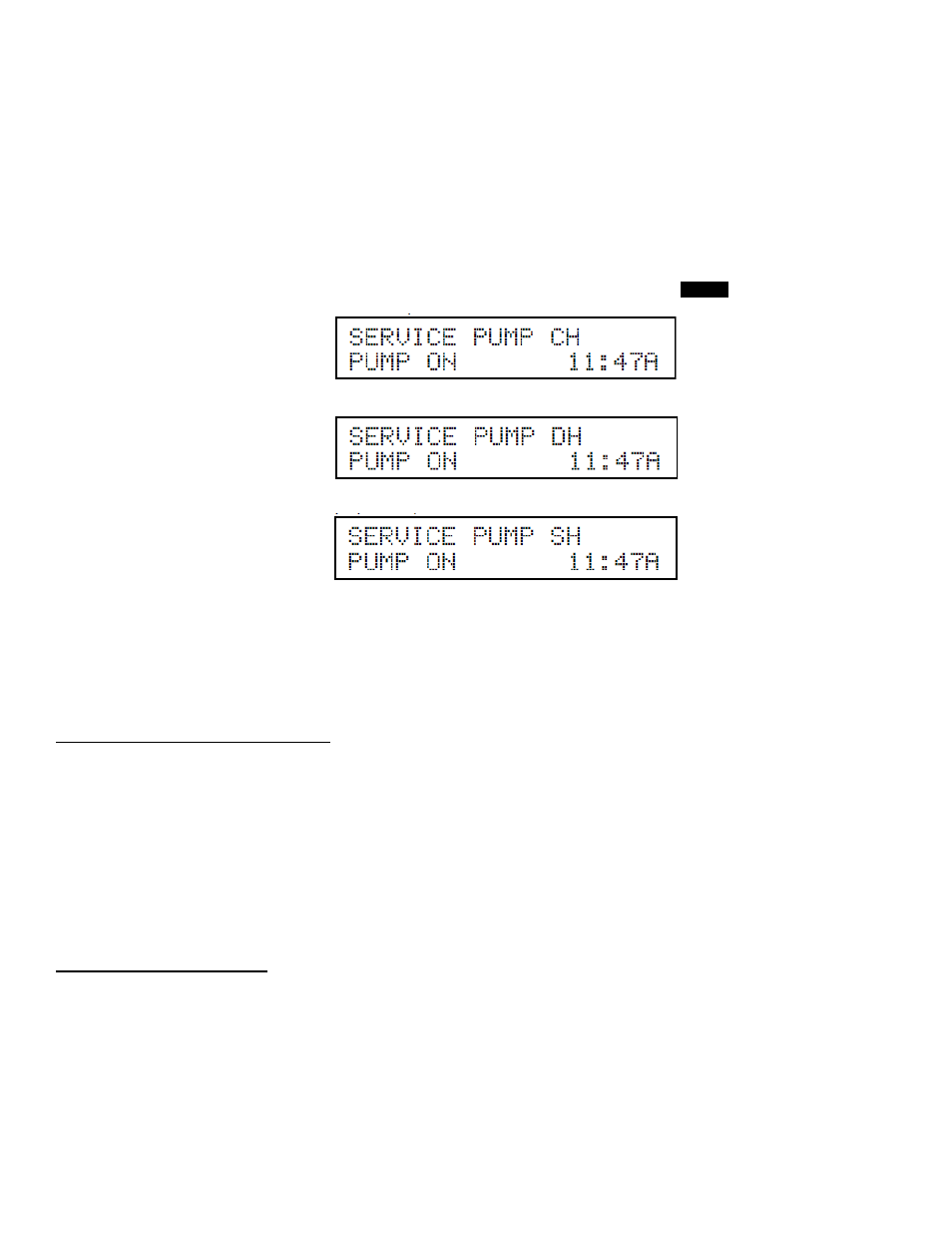

The central heating pump will come on. If you then press the

▲ key, the central heating pump will shut off. The display will

read:

The DHW pump will come on. If the boiler is set up as the cascade master and you press the

▲ key again, the DHW pump will

shut off. The display will read:

The system pump will come on. Use the ▲ and ▼ keys to toggle between running each pump in the system as required to

help bleed out all entrapped air. Some good indicators that air is removed include the absence of gurgling noises in the pipes

and pump operation becoming very quiet. Pressing ▲ and ▼ together at any time will return the boiler to normal operation.

i. After the system has operated for five minutes, eliminate any residual air by using the manual air vents located throughout

the system.

j. If purge valves are not installed in the system, open manual air vents in the system one at a time, beginning with the lowest

floor. Close vent when water squirts out. Repeat with remaining vents.

k. Refill to correct pressure.

F. CHECK THERMOSTAT CIRCUIT(S)

1. Disconnect the two external wires connected to the boiler thermostat terminals (low voltage terminal strip).

2. Connect a voltmeter across these two incoming wires with power supplied to the thermostat circuits. Close each thermostat, zone

valve and relay in the external circuit one at a time and check the voltmeter reading across the incoming wires.

3. There should NEVER be a voltage reading.

4. If a voltage reading does occur under any condition, check and correct the external wiring. (This is a common problem when using 3-

wire zone valves.)

5. Once the external thermostat circuit wiring is checked and corrected if necessary, reconnect the external thermostat circuit wires to

the boiler low voltage terminal strip. Allow the boiler to cycle.

G. CONDENSATE REMOVAL

1. The boiler is a high efficiency condensing boiler. Therefore, the unit has a condensate drain. Condensate fluid is nothing more than

water vapor, derived from combustion products, similar to that produced by an automobile when it is initially started.

Condensation is slightly acidic (typically with a pH of 3 to 5) and must be piped with the correct materials. Never pipe the condensate

using steel, copper, brass or other materials that will be subject to corrosion. Plastic PVC or CPVC pipe are the only approved

materials.

A condensate neutralizer, if required by local authorities, can be made up of lime crystals, limestone or phosphate chips that will

neutralize the condensate. This may be done by the installer or you may purchase a condensate neutralizer from HTP (7450-212).