G. piping details – HTP EL-399 User Manual

Page 19

19

LP- 293 REV. 5.20.14

the glycol solution in the system piping. Example: 50% by volume glycol solution expands 4.8% in volume for a temperature increase

from 32

o

F to 180

o

F, while water expands 3% with the same temperature rise.

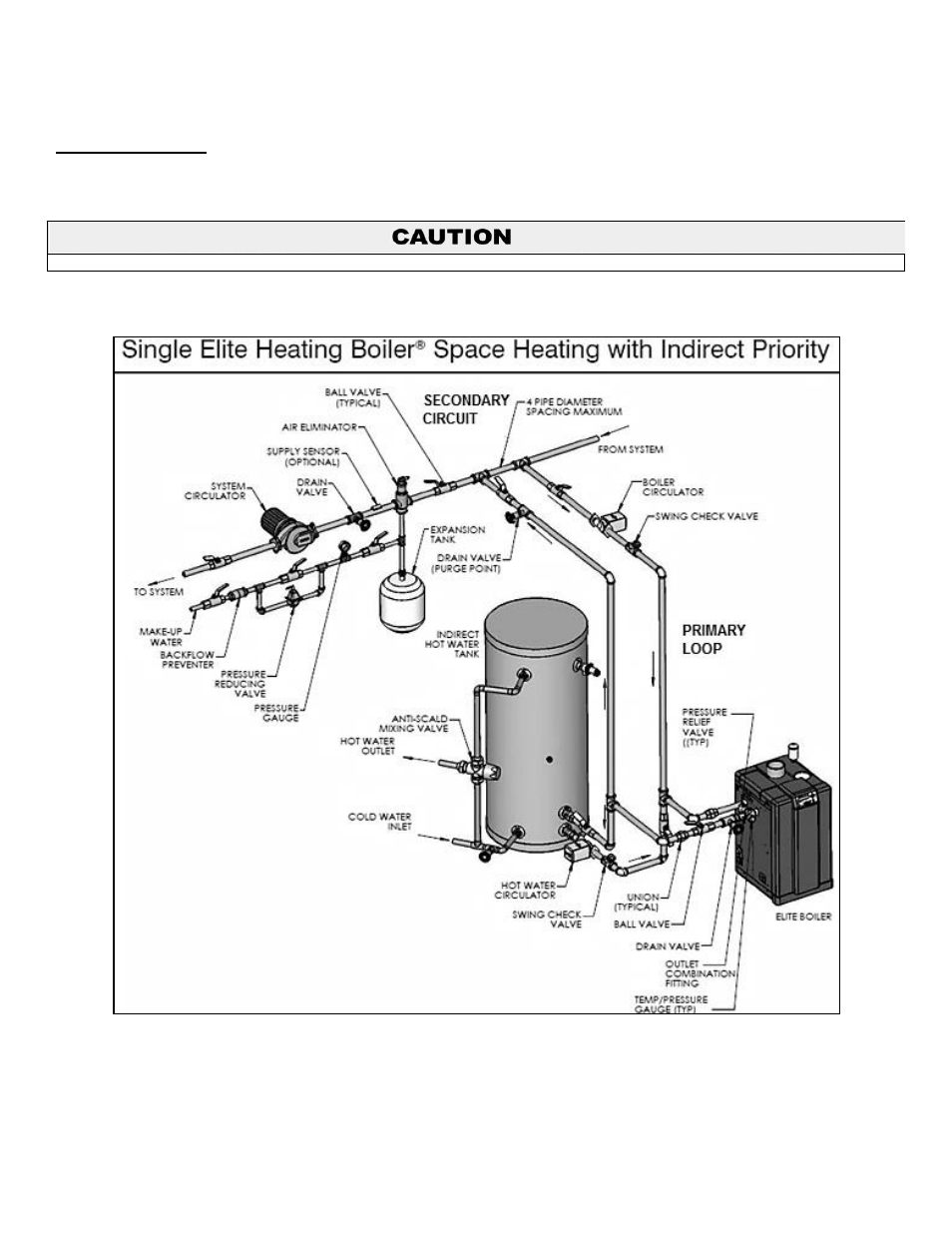

G. PIPING DETAILS*

*NOTE: Systems shown are primary/secondary piping systems. These recommended systems have a primary (boiler) loop, and

secondary circuits for heating. The primary loop and secondary circuits have separate circulators. The use of other near boiler piping

configurations could result in improper flow rates, leading to inadvertent boiler high limit shutdowns and poor system performance.

Mixing valves are required for the protection of low temperature loops.

NOTE: In piping applications utilizing a single zone, it is recommended that the installer use flow / check valves with weighted seats at

or near the appliance to prevent gravity circulation.

Figure 6

– LP-293-L

NOTES: 1. This drawing is meant to show system piping concept only.

2. A mixing valve is recommended if the DHW temperature is set above 119

o

F.

3. Install a minimum of 12 diameters of straight pipe upstream of all circulators.

4. Piping shown is Primary/Secondary.

5. System flow (secondary loop) should be greater than the boiler primary loop flow. In all cases, the boiler primary loop flow rate must be maintained

above the minimum flow rates published on p. 28, this manual.

6. Installations must comply with all local codes.

7. In Massachusetts, a vacuum relief valve must be installed in the cold water line per 248 CMR.