Warning – Harrington Hoists and Cranes MCR Trolley User Manual

Page 38

38

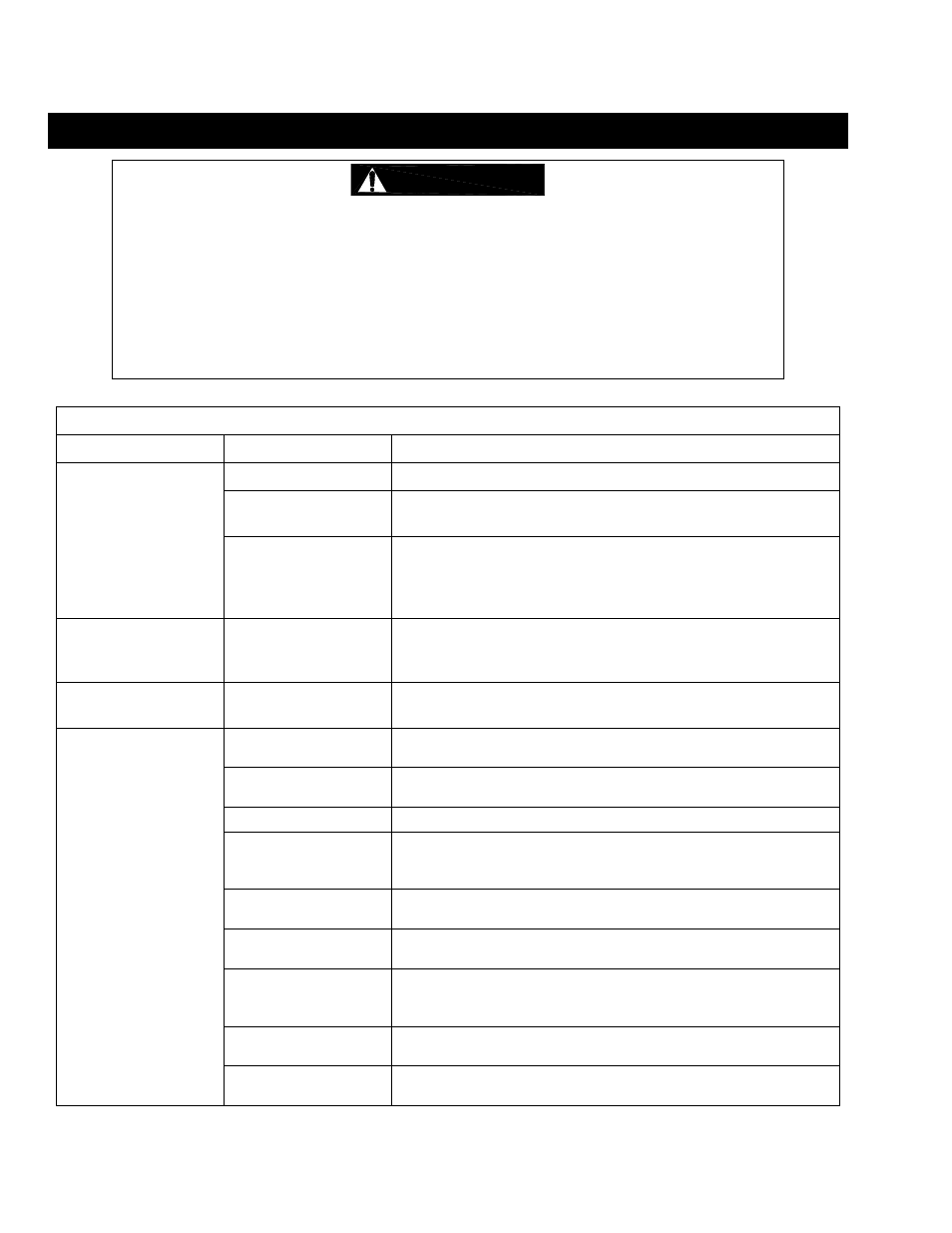

7.0 Troubleshooting

WARNING

HAZARDOUS AIR PRESSURE IS PRESENT IN THE HOIST, IN THE SUPPLY OF

COMPRESSED AIR TO THE HOIST, AND IN THE CONNECTIONS BETWEEN COMPONENTS.

Before performing ANY maintenance on the equipment, de-energize the supply of compressed air to

the equipment, and lock and tag the supply device in the de-energized position. Refer to ANSI

Z244.1, “Personnel Protection - Lockout/Tagout of Energy Sources.”

Only trained and competent personnel should inspect and repair this equipment.

Table 7-1

Troubleshooting Guide

Symptom

Cause

Remedy

Loss of power

Check air tubes, hoses and air supply.

Wrong air volume or

pressure

Check air volume and pressure against the rating on the

nameplate of the trolley.

Trolley will not operate

Improper, loose, or

broken tubing or hoses

in trolley air supply

system

Shut off air supply, check tubing and hose connections at the

hoist, trolley and push-button pendant.

Trolley drifts

excessively when

stopping

Motor brake not

holding

Clean and inspect brake. Replace if necessary. (see

Section 6.3

for Brake Inspection)

Trolley Operates

Intermittently

See Trolley will not

operate

Low air pressure at

hoist inlet port.

Repair or adjust air supply or filters. Check for airline obstruction.

Air supply hose or

piping is too small.

Replace hose or piping sizes with recommended sizes in

Section

3.10

.

Malfunction of brake.

Repair at service facility.

Bending or crimping of

pendant hoses or

control tubes

Correct or repair the bend or crimp in hose and/or control tubes

Lack of sufficient oil in

air supply to trolley

Increase oil in air supply to trolley in accordance with

requirements in

Section 6.1

.

Exhaust Silencer

clogged

Clean or replace.

Air flow capacity of

compressed air

system insufficient

Increase airflow capacity of compressed air system to

requirements in

Section 2.0

.

Air motor vanes or

bearings worn

Repair at service facility.

Traveling speed is

slow

Air supply to hoist

contains dirt or debris

Filter the air supply to the trolley in accordance with the

requirements in

Section 3.8

.