Harrington Hoists and Cranes MCR Trolley User Manual

Page 36

36

6.0 Maintenance & Handling

6.1

Air Trolley Motor Lubrication

6.1.1

See Section 3.7 for lubrication requirements.

6.1.2

CAUTION

Lubrication to the motor will be provided primarily by the air supply lubricator. The

recommended amount is 10-15 drops/minute (2-3cc/min.). Refer to

Table 6-1

below for the approved

lubricant for use with your air hoist.

6.1.3

Additional lubrication to the reduction gears is not necessary. When disassembling the hoist for service

or repair, apply new grease to the gears before reassembling the hoist.

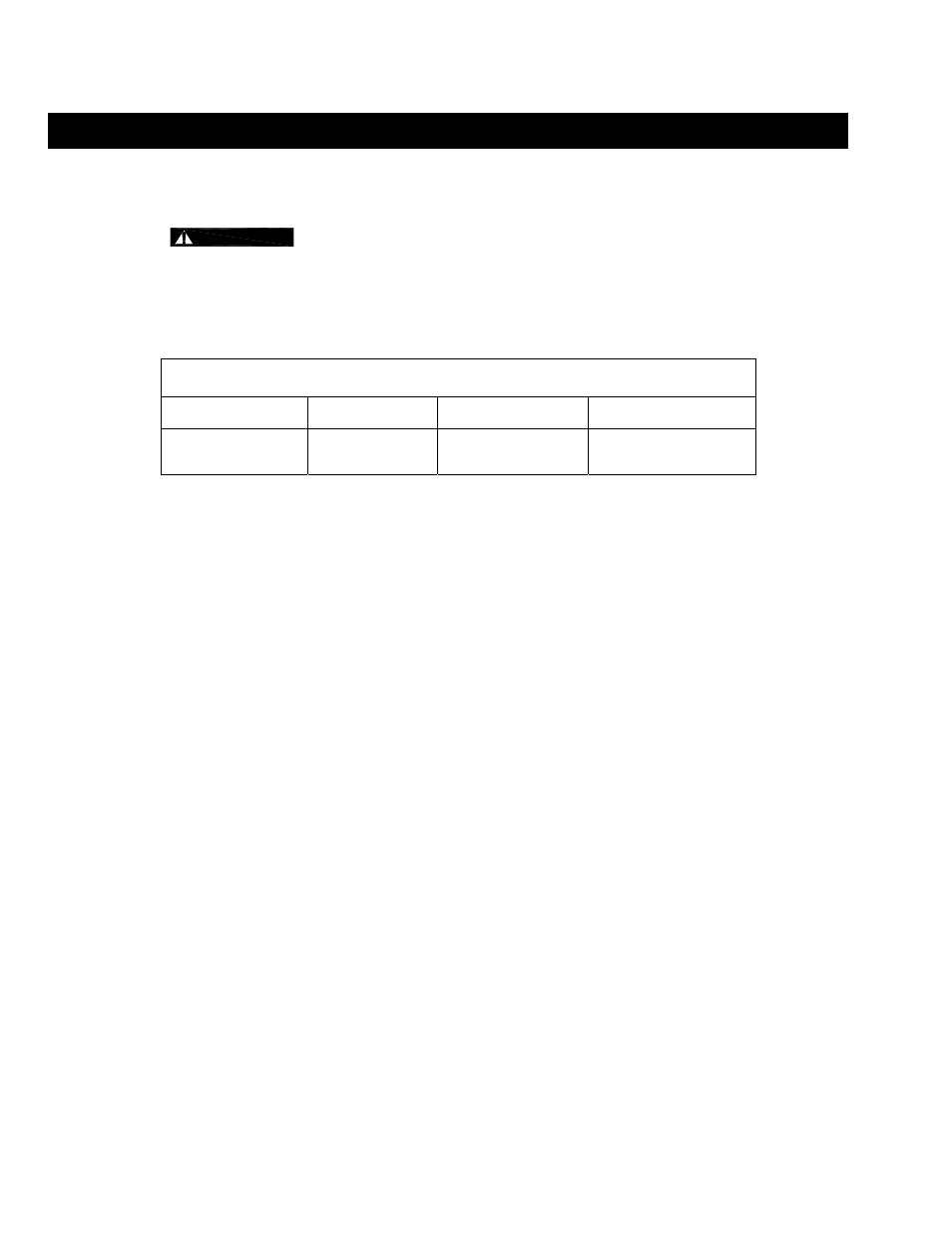

Table 6-1

Table of Approved Lubricants

Lubrication Grade Application Part

Location

Turbine Oil

ISO VG 32-56 or

equivalent

Air motor

Lubricator

6.2 Air

Trolley

Lubrication

6.1.1

Lubricate the following trolley components with NLGI (National Lubricating Grease Institute) #2 or

equivalent grease.

6.1.2

Track Wheel Gear – Clean and re-grease the Track Wheel gears and motor output pinion every three

months (more frequently for heavier usage or severe conditions). Do not use an excessive amount of

grease and avoid getting any grease on the running surfaces of the Track Wheels or the beam.

6.1.3

Gear Box – The reduction gearing in the motor should be cleaned and lubricated at least once per year

for normal usage. Clean and lubricate the reduction gear assembly more frequently for heavier usage

or severe conditions. Gain access to the gears by removing the four bolts that mount the motor

assembly to the trolley Side Plate. Make sure to properly orient and reuse the neoprene gasket

between the motor and Side Plate.

6.1.4

Suspension Pins, Bolts and Shafts – Grease at least twice per year for normal usage (more frequently

for heavier usage or severe conditions).

6.3 Brake

6.1.5

The trolley motor brake is NOT adjustable.

6.1.6

Motor Brake Removal – Evenly remove the four Bolts that attach the Brake Cover to the Case to

release the brake spring. Carefully remove the Cover and brake components.

6.1.7

Brake Inspection – The brake is designed for a long life and should provide years of trouble-free

service. If the brake is being inspected due to excessive trolley drift during operation (see

Section 5.7

),

disassemble the motor brake and inspect all motor brake parts. Braking surfaces should be clean and

smooth. Replace the Brake Drum and/or Brake Piston if necessary. For normal inspections, the Brake

Drum and Brake Piston wear should be measured as follows.

1)

Refer to Table 5-6.

2)

Measure the distance "A" using calipers. Make sure the Brake Piston is square against the Brake

Drum.

3)

Compare the measurement with the values listed in Table 5-6. Replace the Brake Drum and/or

Brake Piston if the "A" measurement exceeds the discard limit.