Harrington Hoists and Cranes MCR Trolley User Manual

Page 33

33

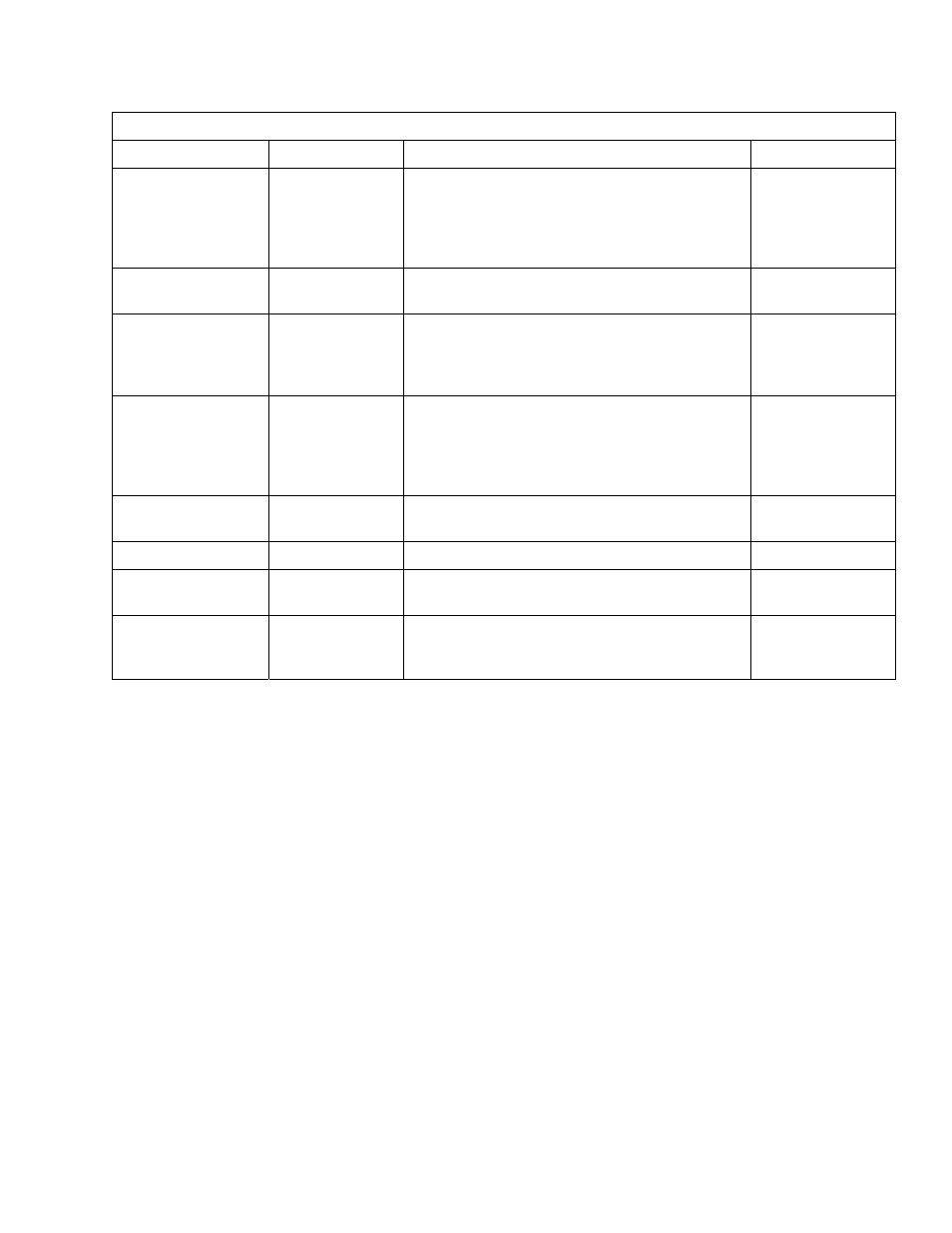

Table 5-3

Trolley Inspection Methods and Criteria

Item Method

Criteria

Action

Pendant – Tubing

Visual

Surface of tubing should be free from nicks,

gouges, and abrasions. Tubing should not leak

even when flexed back-and-forth. Tubing should

not be deformed or loosely connected and free of

significant deterioration.

Replace

Pendant – Buttons

Function

Depressing and releasing push buttons should

start or stop load chain or trolley movement.

Repair or replace

as necessary.

Pendant – Assembly Visual

Pendant Assembly – housing, bracket and conduit

should be free of damage. Pendant Strain Relief

Cable should absorb all of the load associated with

forces applied to the pendant.

Replace.

Air Supply Hoses

Visual, Air Flow

Surface of hose should be free from nicks,

gouges, and abrasions. Hose should not leak

even when flexed back-and-forth. Hose should

not be deformed or loosely connected and free of

significant deterioration.

Replace.

Air Hose Fittings

Visual

All Fittings should not be cracked or damaged.

Repair or replace

as necessary.

Pendant - Labels

Visual

Labels denoting functions should be legible.

Replace.

Warning Labels

Visual

Warning Labels should be affixed to the pendant

cord (see

Section 1.2

) and they should be legible.

Replace.

Trolley Capacity

Label

Visual

The label that indicates the capacity of the trolley

should be legible and securely attached to the

trolley.

Replace.