Harrington Hoists and Cranes SNER Hoist User Manual

Page 35

35

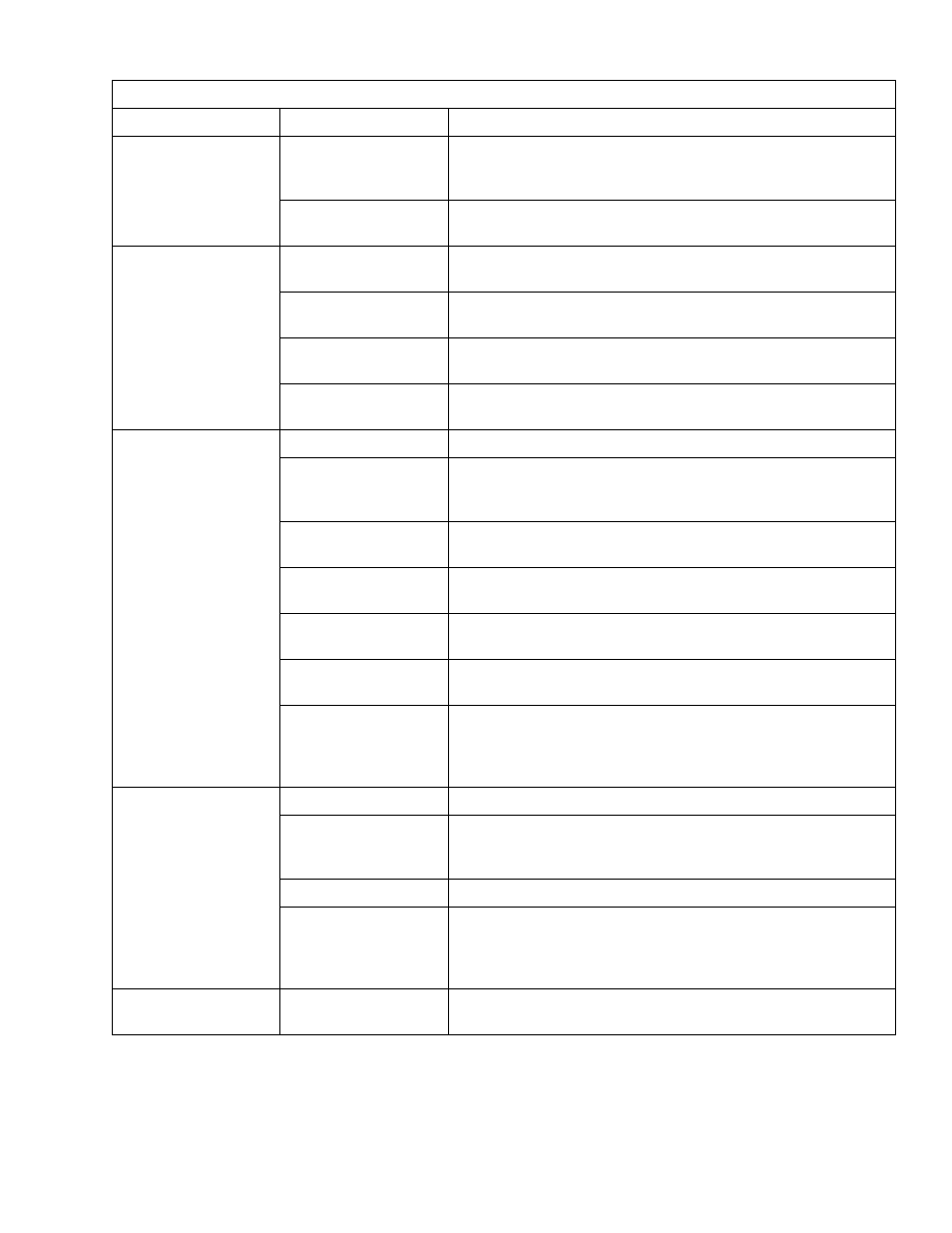

Table 7-1

Troubleshooting Guide

Symptom Cause

Remedy

Hoist will not operate

(continued)

Faulty Start Switch

Disconnect Start Switch from motor. The resistance between the

Start Switch terminals 2 and 3 should be greater than 500K ohms.

If not, consult factory.

Faulty Start

Capacitor(s)

Check capacitor(s) for open or short circuit. Check connections.

Replace as needed.

Hoist lifts but will not

lower

Down circuit open

Check circuit for loose connections. Check down side of limit

switch for malfunction.

Broken conductor in

pendant cord

Check the continuity for each conductor in the cable. If one is

broken, replace entire cable.

Faulty magnetic

contactors

Check coils for open or short circuit. Check all connections on

motor circuit. Check for burned contacts. Replace as needed.

Faulty switch in

pendant

Check electrical continuity. Check electrical connections.

Replace or repair as needed.

Hoist lowers but will

not lift

Hoist overloaded

Reduce load to within rated capacity of hoist.

Low voltage in hoist's

power supply

Determine cause of low voltage and bring to within plus or minus

10% of the voltage specified on the motor nameplate. The

voltage should be measure at the hoist contactor.

Up circuit open

Check circuit for loose connections. Check up side of limit switch

for malfunction.

Broken conductor in

pendant cord

Check the continuity of each conductor in the cable. If one is

broken, replace entire cable.

Faulty magnetic

contactor

Check coils for open or short circuit. Check all connections on

motor circuit. Check for burned contacts. Replace as needed.

Faulty switch in

pendant

Check electrical continuity. Check electrical connections.

Replace or repair as needed.

Faulty friction clutch

If abnormal operation or slippage occurs do NOT attempt to

disassemble or adjust the Friction Clutch. Replace the worn or

malfunctioning Friction Clutch as an assembly with a new, factory

adjusted part.

Hoist will not lift rated

load or does not have

the proper lifting speed

Hoist overloaded

Reduce load to within rated capacity.

Low voltage in hoist's

power supply

Determine cause of low voltage and bring to within plus or minus

10% of voltage specified on the motor nameplate. The voltage

should be measured at the hoist contactor.

Brake drags

Check motor brake adjustment for proper clearance.

Faulty friction clutch

If abnormal operation or slippage occurs do NOT attempt to

disassemble or adjust the Friction Clutch. Replace the worn or

malfunctioning Friction Clutch as an assembly with a new, factory

adjusted part.

Load drifts excessively

when hoist is stopped

Motor brake not

holding

Clean and inspect brake lining. Check brake adjustment for

proper clearance.