Procedures, Polar and non-polar sol – Ransburg EFM & EFMD Solvent Applicator 76480, 76482, 76485, 76488 User Manual

Page 25

AA-99-01.1

2 0

2 0

2 0

2 0

2 0

EFM(D) Solventborne Robotic Atomizers - Maintenance

1. Flush the paint supply line and the applicator

paint passages using a solvent which is compat-

ible with the material being sprayed. Continue to

flush until all traces of paint are gone.

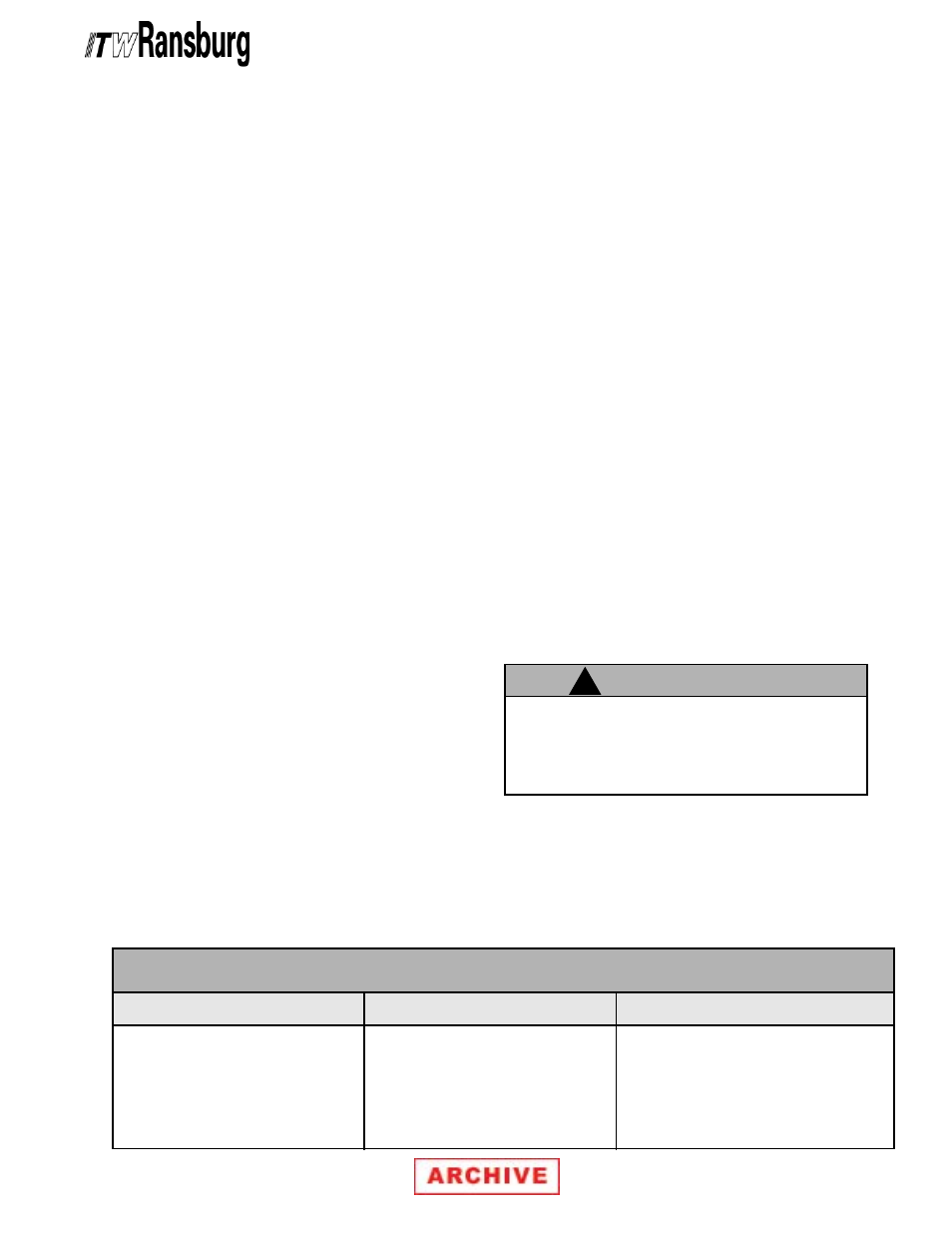

Amyl Acetate

Methyl Amyl Acetate

Toluene

Xylene

High Flash Naptha

Mineral Spirits

Nonconductive (non-polar)

Nonconductive (non-polar)

Nonconductive (non-polar)

Nonconductive (non-polar)

Nonconductive (non-polar)

POLAR AND NON-POLAR SOL

POLAR AND NON-POLAR SOL

POLAR AND NON-POLAR SOL

POLAR AND NON-POLAR SOL

POLAR AND NON-POLAR SOLVENTS

VENTS

VENTS

VENTS

VENTS

Moderately Conductive

Moderately Conductive

Moderately Conductive

Moderately Conductive

Moderately Conductive

Extremely Conductive (polar)

Extremely Conductive (polar)

Extremely Conductive (polar)

Extremely Conductive (polar)

Extremely Conductive (polar)

Methyl

Isobutyl Ketone

Ethyl Acetate

Methyl Ethyl Ketone

Butyl Carbitol

Methanol

Carbitol

Diacetone

Butyl Alcohol

Acetone

Butyl Cellosolve

PROCEDURES

PROCEDURES

PROCEDURES

PROCEDURES

PROCEDURES

Gun Cleaning/Service

Gun Cleaning/Service

Gun Cleaning/Service

Gun Cleaning/Service

Gun Cleaning/Service

(See Figure 5)

(See Figure 5)

(See Figure 5)

(See Figure 5)

(See Figure 5)

2. Turn the LECU5004 MicroPak Control Unit

ON

ON

ON

ON

ON! Energize high voltage.

Shut-Down (Or at Shift End)

Shut-Down (Or at Shift End)

Shut-Down (Or at Shift End)

Shut-Down (Or at Shift End)

Shut-Down (Or at Shift End)

1. Turn the LECU5004 MicroPak Control Unit

OFF.

2. Flush the lines and allow the solvent to remain

in the lines. See "Procedures" in the "Maintenance"

section.

1. Turn the LECU5004 MicroPak Control Unit

OFF.

2. Flush the lines and allow the solvent to remain

in the lines. See "Procedures" in the "Maintenance"

section.

3. Wipe the applicator and robot wrist with a cloth

and a suitable, clean non-polar solvent.

Weekly

Weekly

Weekly

Weekly

Weekly

1. Check the entire system for damage, leaks and

paint accumulation.

2. Clean the atomizer assembly.

3. Conduct a current output test. See "Proced-

ures" in the "Maintenance" section.

2. Turn off the solvent supply, actuate paint

pushout air at color changer and trigger the appli-

cator. Allow all of the fluid to drain from the spray

applicator fluid passages.

3. Clean the exterior surfaces of the spray gun

with a solvent soaked rag. As long as the gun is

intact, a polar

polar

polar

polar

polar solvent may be used for all clean-

ing, however, after cleaning, wipe off all surfaces

with a nonpolar

nonpolar

nonpolar

nonpolar

nonpolar solvent to reduce conductive

residue on the applicator's surface. See "Polar

and Non-Polar Solvents" below regarding proper

solvent selection.

4. Remove piston cap [1]. Removing the piston

cap releases tension on all internal spray head

components. Remove spring retainer [2] and

piston spring [3], which are loose after removing

the piston cap.

5. Remove the air cap retainer [21] and air cap

[20]. Soak in a non-polar solvent if necessary. If

paint remains in the air cap holes, clean with a

toothpick or similar soft wood object. Air caps are

best cleaned in an ultrasonic cleaner.

>

Never attempt to clean the air cap holes

with a wire or other metal object. Doing so

may damage the air cap, resulting in distor-

tion of the spray pattern.

C A U T I O N

C A U T I O N

C A U T I O N

C A U T I O N

C A U T I O N

!!!!!