Aerobell m rotary atomizer - maintenance – Ransburg Aerobell M Rotary Atomizer 78101 User Manual

Page 35

LN-9237-00.1

Aerobell M Rotary Atomizer - Maintenance

31

31

31

31

31

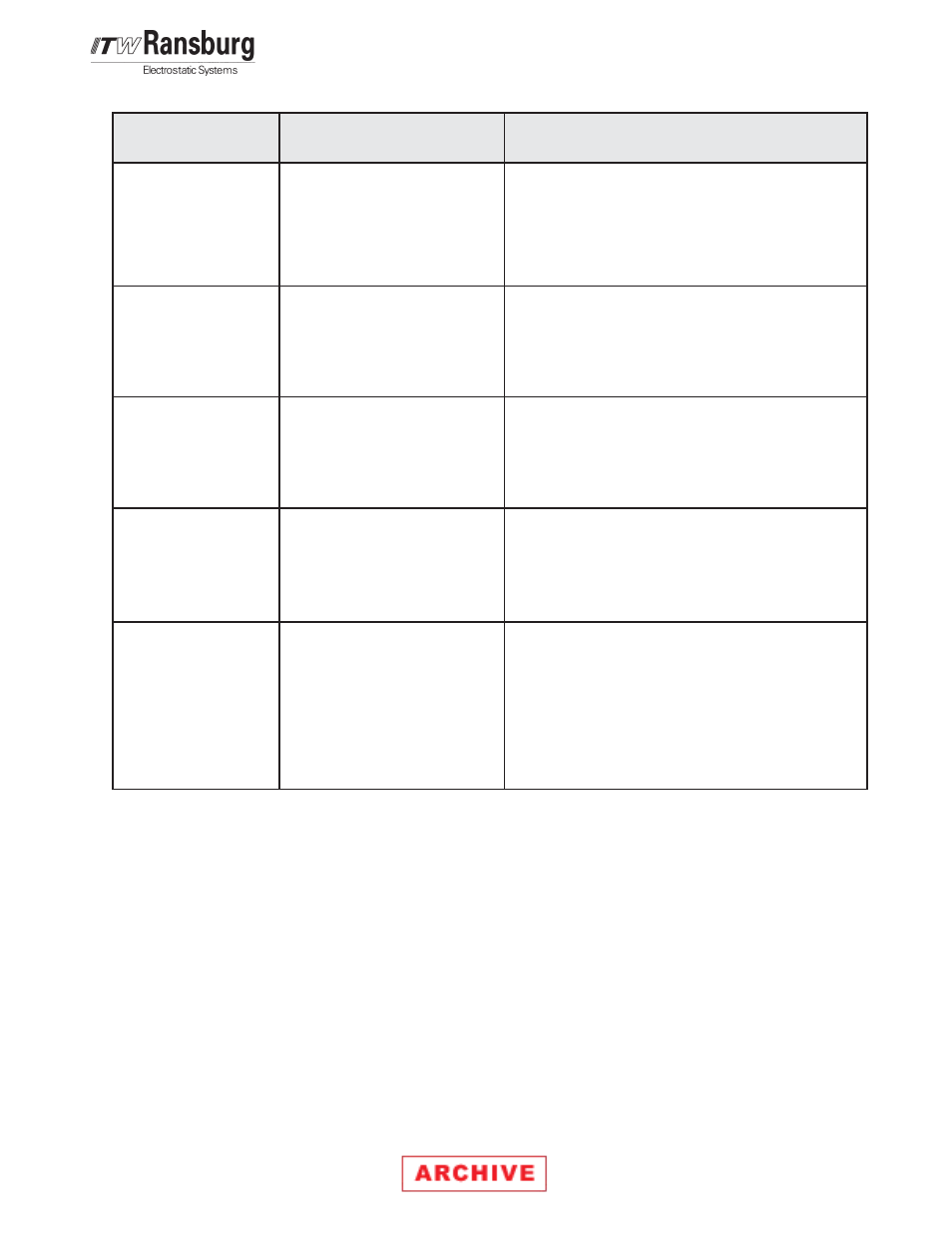

Figure 15: Troubleshooting Guide (Continued)

Figure 15: Troubleshooting Guide (Continued)

Figure 15: Troubleshooting Guide (Continued)

Figure 15: Troubleshooting Guide (Continued)

Figure 15: Troubleshooting Guide (Continued)

General Problem

General Problem

General Problem

General Problem

General Problem

Possible Causes

Possible Causes

Possible Causes

Possible Causes

Possible Causes

Corrective Action

Corrective Action

Corrective Action

Corrective Action

Corrective Action

No Fluid Flow

(Continued)

Continuous Fluid Flow

Uncontrollable Fluid

Flow

Fluid Leakage Around

Fluid Valve

Fluid Leakage Around

the Fluid Regulator

Cap

3.

Fluid valve does not actu-

ate

4.

Clogged fluid tube

1.

Fluid valve open

2.

Fluid valve seat damaged

or

worn

1.

Insufficient back pressure

to fluid regulator

2.

Fluid regulator does not

control flow

1.

Damaged o-ring(s) on outer

diameter of valve body

2.

Damaged or worn needle

seals inside valve assem-

bly

1.

Regulator cap is loose

2.

Ruptured diaphragm

3.

Pinched or cut o-ring

between lower support

washer and diaphragm

3a. Verify that air pilot signal is present.

b. Fluid valve air pilot pressure is too low.

Increase air pressure to 70 psig minimum.

c. Replace fluid valve.

4.

Remove and inspect fluid tube.

1a. Remove air pilot signal.

b. If still open, replace fluid valve.

2.

Replace fluid valve seat.

1.

Replace fluid tube with the next smaller inner

diameter size.

2.

Disassemble fluid regulator and inspect for

failed components.

1.

Replace o-ring(s).

2.

Replace valve assembly.

1.

Disassemble, clean, and reassemble. Tighten

regulator cap hardware.

2.

Replace diaphragm.

3.

Replace o-ring.