Aerobell m rotary atomizer - operation – Ransburg Aerobell M Rotary Atomizer 78101 User Manual

Page 19

LN-9237-00.1

Aerobell M Rotary Atomizer - Operation

(i.e. from 1:2 to 1:4) provides a lower slope, but,

more precise response curve. This same in-

crease in ratio, however, will reduce flow capac-

ity and should be considered when selecting the

proper regulator ratio.

The following factors must then be considered

when selecting the regulator ratio required for

proper fluid control:

• Maximum fluid output requirements (Guide:

10

psi minimum, 30 psi max.)

• Fluid tubing inside diameter (ID) and length

• Fluid feed tube inside diameter (ID) and length

• Fluid viscosity

• Fluid input pressures (Guide: 10 psi above

max. fluid output pressure)

Only proper testing will determine which regula-

tor ratio should be used. If conditions change

after installation which require a different low

flow ratio, this regulator can be altered easily by

replacing the existing ratio spacer ring and up-

per retainer with the desired ratio (ratio designa-

tion is etched on the side of the spacer ring).

The output of the regulator is externally con-

nected to a fitting on the fluid manifold assem-

bly. The fluid manifold assembly is equipped

with valves which are pneumatically operated to

direct the flow of paint to either the feed tube or

dump line and to supply a intermittent solvent

bell wash for the feed tube and bell cup.

The feed tube is available in several sizes (See

Figure 11). The viscosity and volume of the

coating material being sprayed determine the

correct size of feed tube for each installation.

The feed tube diameter acts as a linear

restrictor to create back pressure on the fluid

regulator so that it can provide accurate and re-

peatable flow to air signal resolution.

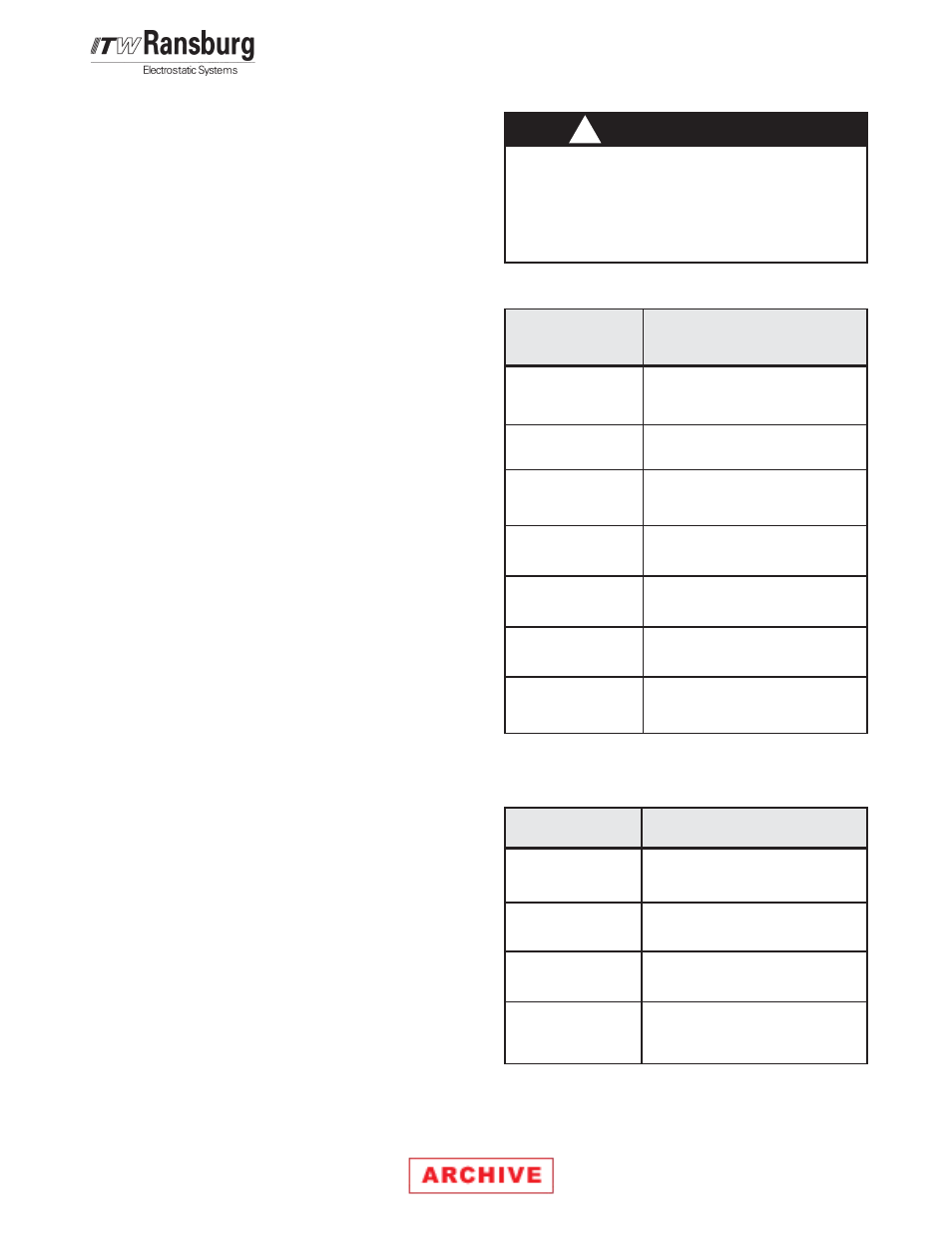

Figure 10: Fluid Regulator Selections

Figure 10: Fluid Regulator Selections

Figure 10: Fluid Regulator Selections

Figure 10: Fluid Regulator Selections

Figure 10: Fluid Regulator Selections

Low Flow Rates

Low Flow Rates

Low Flow Rates

Low Flow Rates

Low Flow Rates

1:1

1:2

1:3

1:4

1:6

1:8

1:10

Fixed Atomizer

Fixed Atomizer

Fixed Atomizer

Fixed Atomizer

Fixed Atomizer

Regulator Part No.

Regulator Part No.

Regulator Part No.

Regulator Part No.

Regulator Part No.

LREG5001-01

LREG5001-02

LREG5001-03

LREG5001-04

LREG5001-06

LREG5001-08

LREG5001-10

Fluid Flow Rate Check:

Fluid Flow Rate Check:

Fluid Flow Rate Check:

Fluid Flow Rate Check:

Fluid Flow Rate Check:

In test mode, the flow rate can be measured by

removing the bell cup from the atomizer, turning

the fluid flow on and capturing the material in a

graduated beaker or measuring cup for a fixed

period of time (shaping air, high voltage and tur-

bine air must be off).

>

Danger of shock and/or personal injury

can occur. Proper grounding procedures

must be followed. Personnel must never

work around the turbine when the turbine is

spinning or when high voltage is turned on.

W A R N I N G

W A R N I N G

W A R N I N G

W A R N I N G

W A R N I N G

!!!!!

15

15

15

15

15

Figure 11: Fluid Tube Selections

Figure 11: Fluid Tube Selections

Figure 11: Fluid Tube Selections

Figure 11: Fluid Tube Selections

Figure 11: Fluid Tube Selections

Orifice Size

Orifice Size

Orifice Size

Orifice Size

Orifice Size

.041 I.D.

.061 I.D.

.093 I.D.

.125 I.D.

Part No.

Part No.

Part No.

Part No.

Part No.

77971-04

77971-06

77971-09

77971-13