Archive, Rem automatic applicator - maintenance – Ransburg REM Automatic Applicator 73499 User Manual

Page 28

AA-87-02.3

2 3

2 3

2 3

2 3

2 3

REM Automatic Applicator - Maintenance

2. Push front u-cup seal [9] on the needle shaft

[11] with the dished outside to the front of the needle

shaft [11].

3. Place spreader seal [8] on needle shaft [11]

with flatest side toward the front of the needle shaft

[11].

4. Place jam nut [7A] on the threads of the needle

shaft [11] and tighten until it reaches the bottom of

the threads. Place ball valve needle [7] on shaft

and finger tighten it until the threads bottom out.

then with the two 2.5mm wrenches, tighten the

jam nut [7A] against the ball valve neelde [7].

>

Apply a heavy coating of dielectric

grease to the seals.

N O T E

N O T E

N O T E

N O T E

N O T E

5. Insert the valve seal [6] and valve seat body

[5] into the front of the barrel [18], chamber [102]

and tighten snuggly.

6. Coat the plastic portion of the needle shaft [11]

with dielectric grease and slide the packing tube

[12] over the plastic portion of the needle shaft

[11].

7. Slide the rear seal container [13], with the o-

ring gland on the outside, toward the front of the

needle shaft [11].

8. Install the o-ring [13A] onto the outside of the

rear seal container [13].

9. Carefully put rear u-cup seal [14] with the o-

ring to the rear of the needle shaft [11].

10. Put the rear seal retainer [15] onto the needle

shaft [11]. Grease the full assembly.

11. Place the packing nut [16] on the rear threads

of the needle shaft [11]. Insert the full assembly

into the barrel [103] and tighten Item 16 with the

spanner wrench.

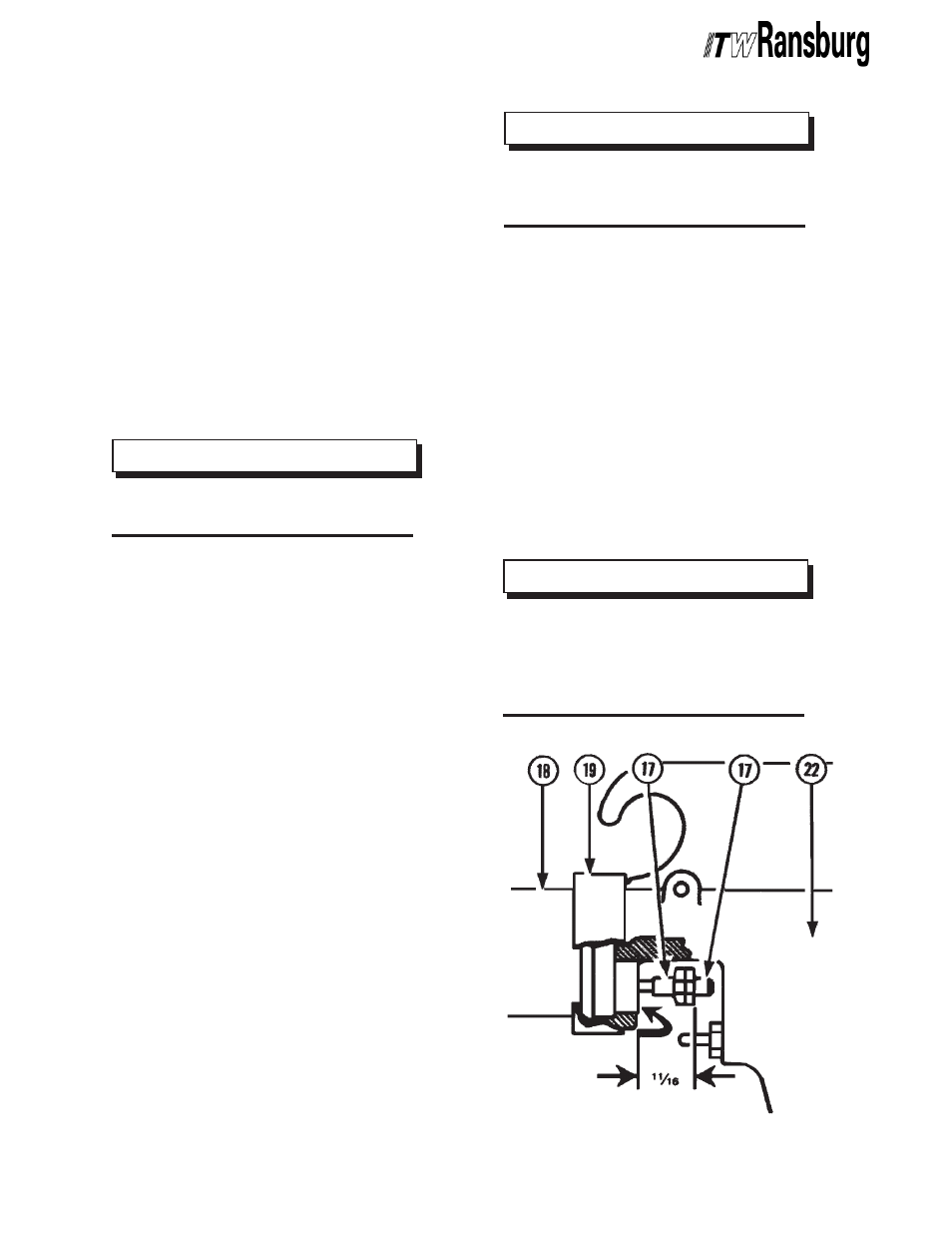

12. Screw the trigger adjusting nut [17] and

extension valve rod [22] onto shaft [11] with the

hexagonal flange or nut facing each other.

13. To adjust nuts [17]:

a. Push needle shaft assembly [11] fully

forward until ball end [7] on shaft [11] seats

in valve seat [5].

b. Measure 11/18-inch from rear lip of barrel/

cascade chamber [103] to the rear face of

the hexagonal flange of the nut on the

extension rod [22].

>

The packing nut should be just tight

enough that shaft [11] slides in and out

with firm resistance.

N O T E

N O T E

N O T E

N O T E

N O T E

>

The 11/16-inch dimension is a starting

point. Because of component stack-up,

wear and other variables, a slight in-

crease or decrease in this setting may be

needed.

N O T E

N O T E

N O T E

N O T E

N O T E

Figure 1: Nut Adjustment

Figure 1: Nut Adjustment

Figure 1: Nut Adjustment

Figure 1: Nut Adjustment

Figure 1: Nut Adjustment

ARCHIVE