Archive, Rem automatic applicator - maintenance – Ransburg REM Automatic Applicator 73499 User Manual

Page 24

AA-87-02.3

1 9

1 9

1 9

1 9

1 9

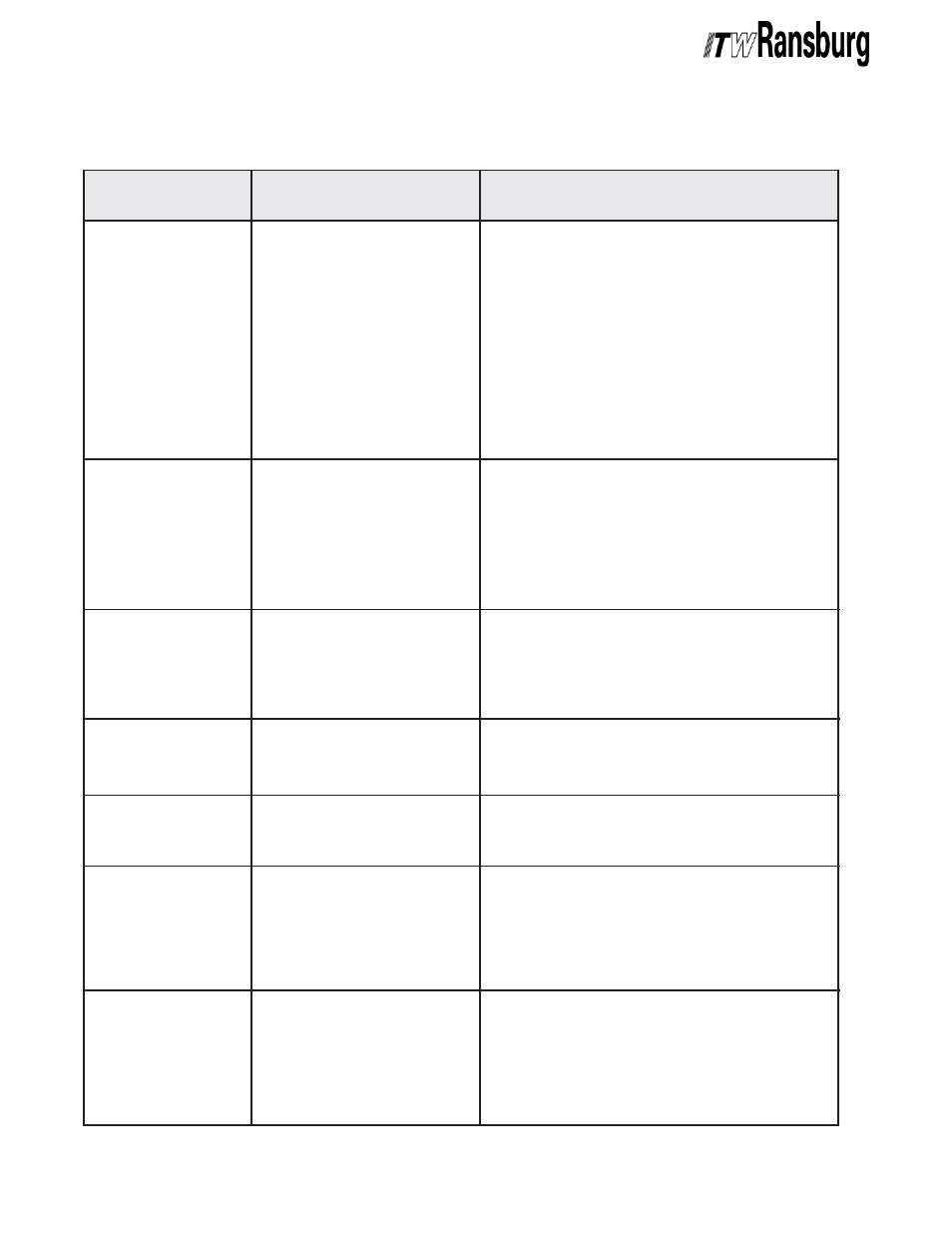

REM Automatic Applicator - Maintenance

T

T

T

T

Troubleshooting Guide (Cont.)

roubleshooting Guide (Cont.)

roubleshooting Guide (Cont.)

roubleshooting Guide (Cont.)

roubleshooting Guide (Cont.)

General Problem

General Problem

General Problem

General Problem

General Problem

Possible Causes

Possible Causes

Possible Causes

Possible Causes

Possible Causes

Corrective Action

Corrective Action

Corrective Action

Corrective Action

Corrective Action

Excessive

Excessive

Excessive

Excessive

Excessive

Surging

Surging

Surging

Surging

Surging

Persistent Nozzle

Persistent Nozzle

Persistent Nozzle

Persistent Nozzle

Persistent Nozzle

Clogging

Clogging

Clogging

Clogging

Clogging

Paint Leaks

Paint Leaks

Paint Leaks

Paint Leaks

Paint Leaks

through Center of

through Center of

through Center of

through Center of

through Center of

Nozzle (Failure to

Nozzle (Failure to

Nozzle (Failure to

Nozzle (Failure to

Nozzle (Failure to

Shut Off)

Shut Off)

Shut Off)

Shut Off)

Shut Off)

Paint leaks

Paint leaks

Paint leaks

Paint leaks

Paint leaks

Arount the Nozzle

Arount the Nozzle

Arount the Nozzle

Arount the Nozzle

Arount the Nozzle

Cap

Cap

Cap

Cap

Cap

Paint Leaks at

Paint Leaks at

Paint Leaks at

Paint Leaks at

Paint Leaks at

Applicator Fluid

Applicator Fluid

Applicator Fluid

Applicator Fluid

Applicator Fluid

Inlet

Inlet

Inlet

Inlet

Inlet

Orange Peel or

Orange Peel or

Orange Peel or

Orange Peel or

Orange Peel or

Rough Finish

Rough Finish

Rough Finish

Rough Finish

Rough Finish

Paint Runs or has

Paint Runs or has

Paint Runs or has

Paint Runs or has

Paint Runs or has

Poor Hiding

Poor Hiding

Poor Hiding

Poor Hiding

Poor Hiding

Qualities

Qualities

Qualities

Qualities

Qualities

1. Restriction in pump air line

2. Insufficient pump capacity

3. Clogged paint filter

4. Low air volume capacity

5. Nozzle too large

6. Discharge lines too short to

dampen surging

1. Paint allowed to dry in

nozzle or line

2. Paint applicator filter too

coarse or damaged

3. Paint pigments too coarse

1. Packing too tight

2. Improper trigger adjustment

3. Defective or dirty valve seat

1. Loose nut

2. Seals worn

1. Thread leaks at high pres-

sure

1. Evaporation rate too fast

2. Poor atomization

3. Viscosity too high

1. Low solids paint

2. Low viscosity

3. Excessive delivery

1. Remove restriction.

2. Secure larger pump or reduce output.

3. Service or replace.

4. Check factory air capacity.

5. Replace with correct nozzle.

6. Install surge suppressor.

1. Flush lines with solvent after each use.

2. Replace or change to finer screen paint filter.

3. Pre-filter paint and/or use larger nozzle orifice.

1. Back off on packing nut.

2. Readjust.

3. Flush out or replace as necessary.

1. Clean paint from needle shat and tighten nut.

2. Replace seals.

1. Tighten nut.

1. Use slower evaporating solvent.

2. See “Poor Atomization”.

3. Add solvent or heat.

1. Use less solvent.

2. Use less solvent.

3. Use smaller nozzle, wider fan angle, lower

pump pressure.

ARCHIVE