Ransburg, Troubleshooting guide, No. 2 process electric motor version - maintenance – Ransburg No. 2 Process Handgun Electric Motor User Manual

Page 44

No. 2 Process Electric Motor Version - Maintenance

Ransburg

40

AH-13-01.1

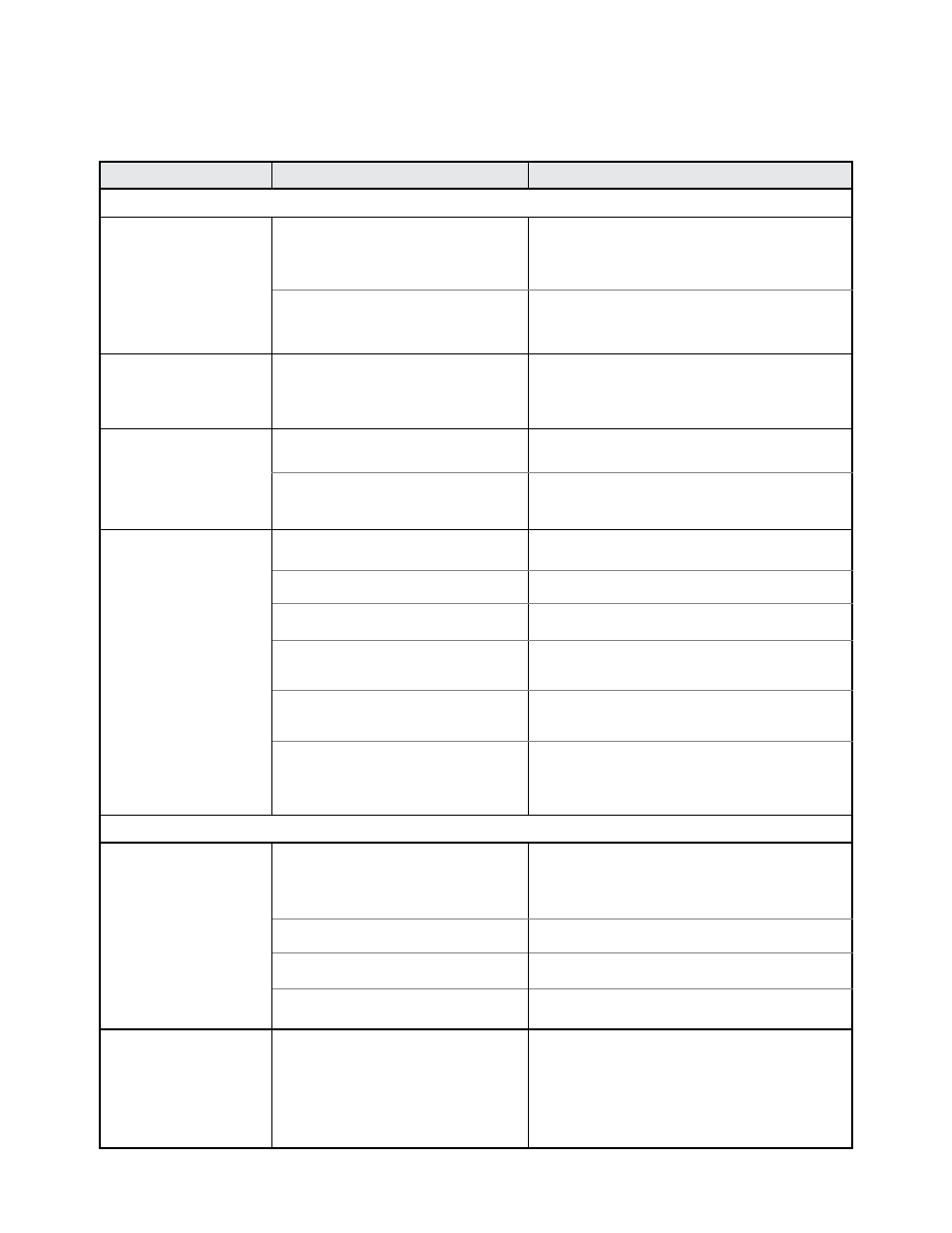

General Problem

Possible Cause

Solution

ELECTRICAL

MECHANICAL (Cont.)

Paint Drips From

Paint Hose Con-

nection or Rear of

Applicator

Hose fittings not tight

Hose broken or worn

Fluid hose fittings are all Left Handed

threads. Insure each connection is properly

secured.

Order replacement or remove fitting, cut off

defective area and replace fitting.

Paint Leaks from

Inside Hand Grip or

trigger Mechanism

Needle packing worn

Adjust packing nut or rebuild handle and

replace packing.

Paint Leaks From

Barrel and Handle

Assembly

Connections

O-ring worn or missing

Paint bushing missing

Replace O-ring

Insure paint busing is properly installed

Large Hole in the

Center of the

Pattern

Bell probe electrically dead

Spring missing in back of bell

Spring not contacting end of shaft

Ground resistor damaged or not

contacting

Spring in ground resistor missing

or not contacting

Contaminated hub leaking high

voltage to the probe

Replace.

Replace.

Clean or replace.

Replace.

Replace.

Clean or replace hub assembly.

Poor Attraction

Target parts not properly grounded

to earth ground

Bell outer coating damaged

Paint too conductive

Low short circuit current

Strip workholders and ground wires of built

up paint to ensure proper earth ground or

check ground wires to parts.

Replace bell.

See “solvent Selection”.

Perform SCI tests.

Poor Atomization

(See First “Me-

chanical Trouble-

shooting”)

Perform tests: See “Electrical Testing”

Contact your Ransburg Distributor

Atomizing voltage too low

TROUBLESHOOTING GUIDE

(Cont.)