Fluid fitting installation procedure, Installation feed tube, bell, brush, Ransburg – Ransburg No. 2 Process Handgun Electric Motor User Manual

Page 16

No. 2 Process Electric Motor Version - Installation

Ransburg

12

AH-13-01.1

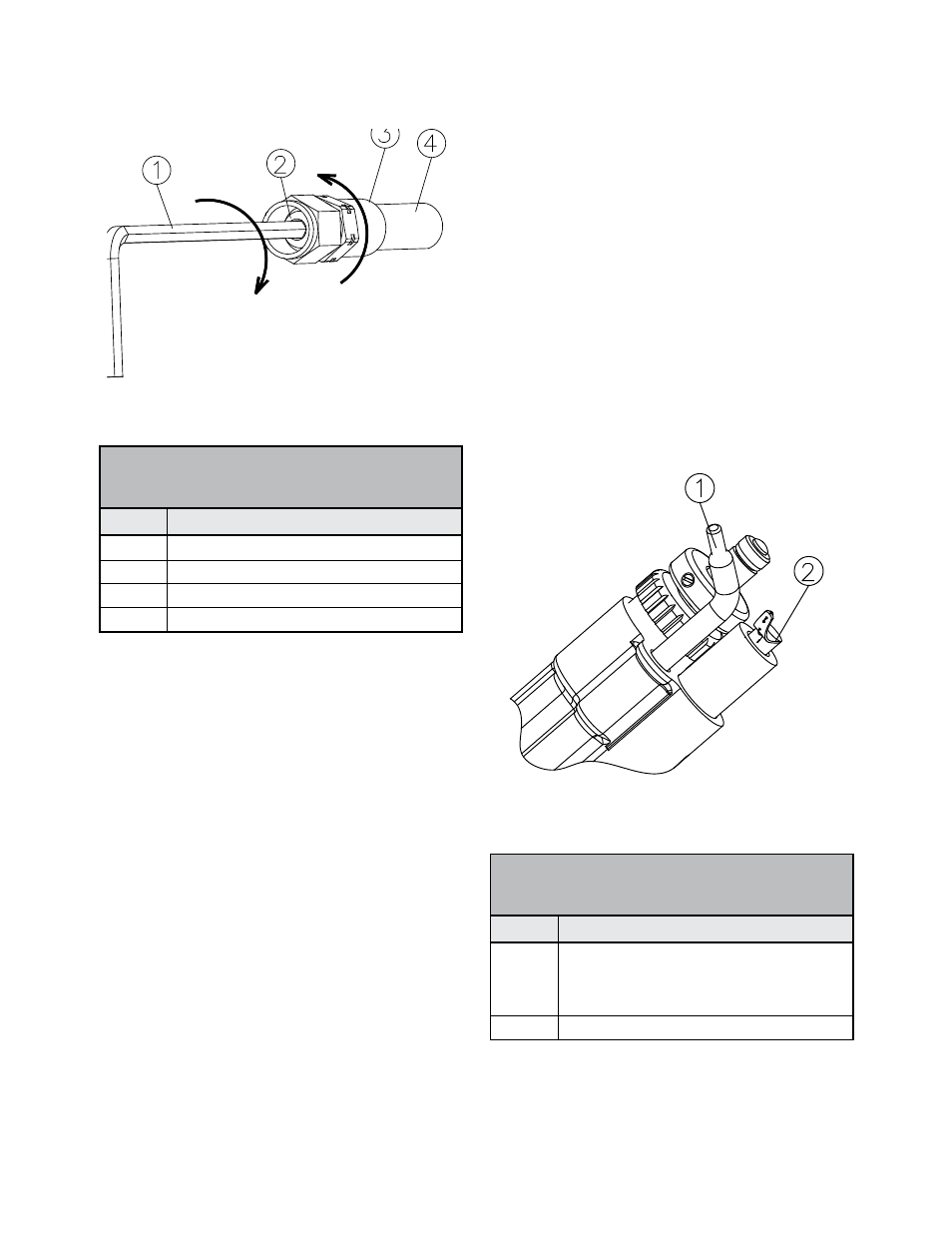

Figure 5: Fluid Fitting Assembly Procedure

FLUID FITTING

INSTALLATION

PROCEDURE

1. Lubricate all fittings with dielectric grease.

2. Screw ferrule (item 3) counterclockwise onto

hose (item 4) until it bottoms, then back it off ap-

proximately 3.2 mm (1/8”).

3. Install nut over union stem and start the stem

into the hose.

4. Using a 4.5 mm hex key (3/16-inch ), screw

the union stem into the hose until it bottoms

against the ferrule.

INSTALLATION FEED

TUBE, BELL, BRUSH

1. Install the proper feed tube into the opening in

the applicator. See figure 6. Position the tube at

approximately as shown in the figure.

2. Insert the 3695-00 (item 2) brush into the bar-

rel. Position it as shown in figure 6.

3. Install the bell over the shaft. Hold the shaft of

the applicator and rotate the bell onto the shaft

until the bell is completely seated. Align the set

screw and the flat on the shaft. Tighten the set

screw at the bell hub hand tight. (Refer to Figure 7)

Figure 6: Initial Position of Feed Tube

and Brush

Item #

1

2

3

4

FLUID FITTING ASSEMBLY

PROCEDURE

(Figure 5)

Description

4.5 mm (3/16”) Hex Key

Stem

Ferrule

Hose, Fluid

Item #

1

2

INITIAL POSITION OF FEED

TUBE AND BRUSH

(Figure 6)

Description

Feed Tube 3700-00 for 4” Bell

Feed Tube 6335-00 for 2 3/4” Bell

Feed Tube 4076-00 for 6” Bell

3695-00 Brush