Accessory installation, Ransburg, Installing bell on shaft – Ransburg No. 2 Process Handgun Electric Motor User Manual

Page 17: Bell cleaning can gun holder

No. 2 Process Electric Motor Version - Installation

Ransburg

13

AH-13-01.1

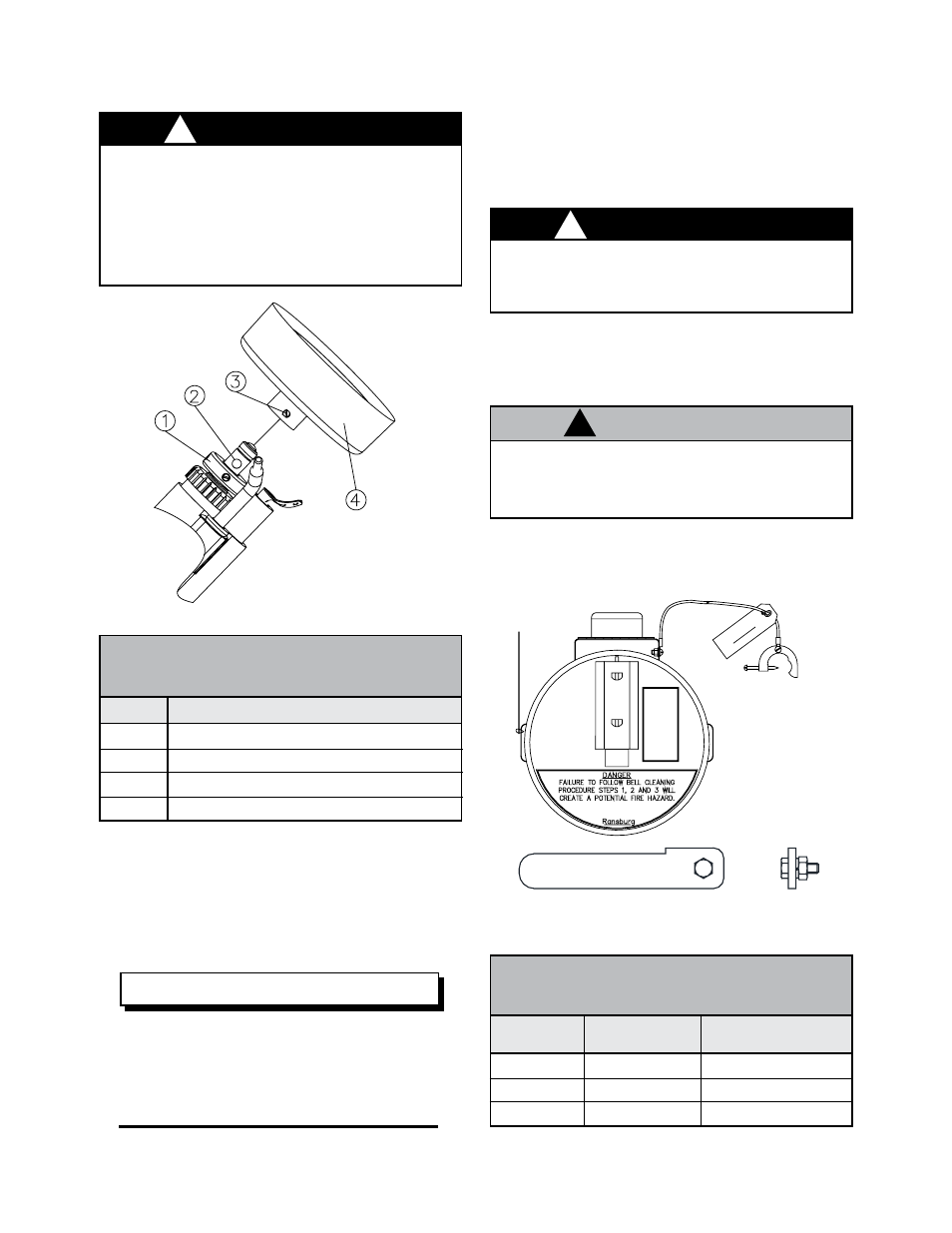

Figure 7: Installing Bell

on Shaft

4. Re-position the feed tube in the bell cavity at

approximately the 4 to 5 o’clock position. The

feed tube should NOT rub on the bell. Adjust the

feed tube if necessary, by rotating it or sliding it

forward or backward in the barrel.

The bell and feed tube MUST be

matched to ensure proper fluid feed into

the bell cavity. The following chart will as-

sist in selecting the proper bell and feed

tube combination:

Figure 8: Bell Cleaning Can and Gun Holder

Bell Cup Cleaning

Can 5170

Gun Holder 3936

NOTE

The Bell Cleaning Can provides a convenient and

portable method of removing excess materials

from the bell cup at the conclusion of spray.

Item #

1

2

3

4

INSTALLING BELL ON SHAFT

(Figure 7)

Description

No. 2 Motor Shaft

Shaft Locating Flat

Bell Set Screw

Bell

Bell Size

2 3/4 “

4”

6”

BELL CLEANING CAN GUN

HOLDER

(Figure 8)

Feed Tube #

6335-00

3700-00

4076-00

Position of Tube

@2 o’clock

@4-5 o’clock

@4-5 o’clock

W A R N I N G

!

Insure ground line of the bell cleaning can

is attached to true earth ground when either

solvent is stored in the can or the can in use.

W A R N I N G

!

Replacing the plastic set screw with one

of conductive material (metal) will cause a

hazardous condition to exist, capable of pro-

ducing an electrical discharge possible of

sparking a fire. In all cases use the plastic

screw provided or provided as a spare part.

Insure any cleaning solvent used meets

criteria listed in the maintenance section of

this manual.

C A U T I O N

!

The gun holder provides a method to mount and

store the applicator when not in use.

ACCESSORY INSTALLATION

Included with the unit are two accessory items:

• Bell cleaning can and the gun holder.