Ransburg, No. 2 process electric motor version - maintenance, Ground resistor removal – Ransburg No. 2 Process Handgun Electric Motor User Manual

Page 38

No. 2 Process Electric Motor Version - Maintenance

Ransburg

34

AH-13-01.1

If any such damage is found the resistor housing

(Item 5) needs to be replaced. Contact an au-

thorized Ransburg representative to replace the

resistor housing if damaged.

After two to four resistors failing, the

resistor housing may be permanently con-

taminated and require replacement.

DO NOT OVERTIGHTEN the screw when

securing the resistor. The ceramic resistor

will be damaged.

9. Place a new O-ring (Item 2) onto resistor seal

(Item 3). Apply a thin coating of petroleum jelly to

the O-ring and insert the resistor seal (side with

hole first) into the front end of resistor housing

(Item 5). Push the resistor seal (Item 3) into re-

sistor housing until it contacts the resistor (Item

4). Insert the contact brush (Item 1).

10. Install cable assembly and motor assembly

onto the rear of the barrel. See “Cable Assembly

Replacement” procedures in the “Maintenance”

section.

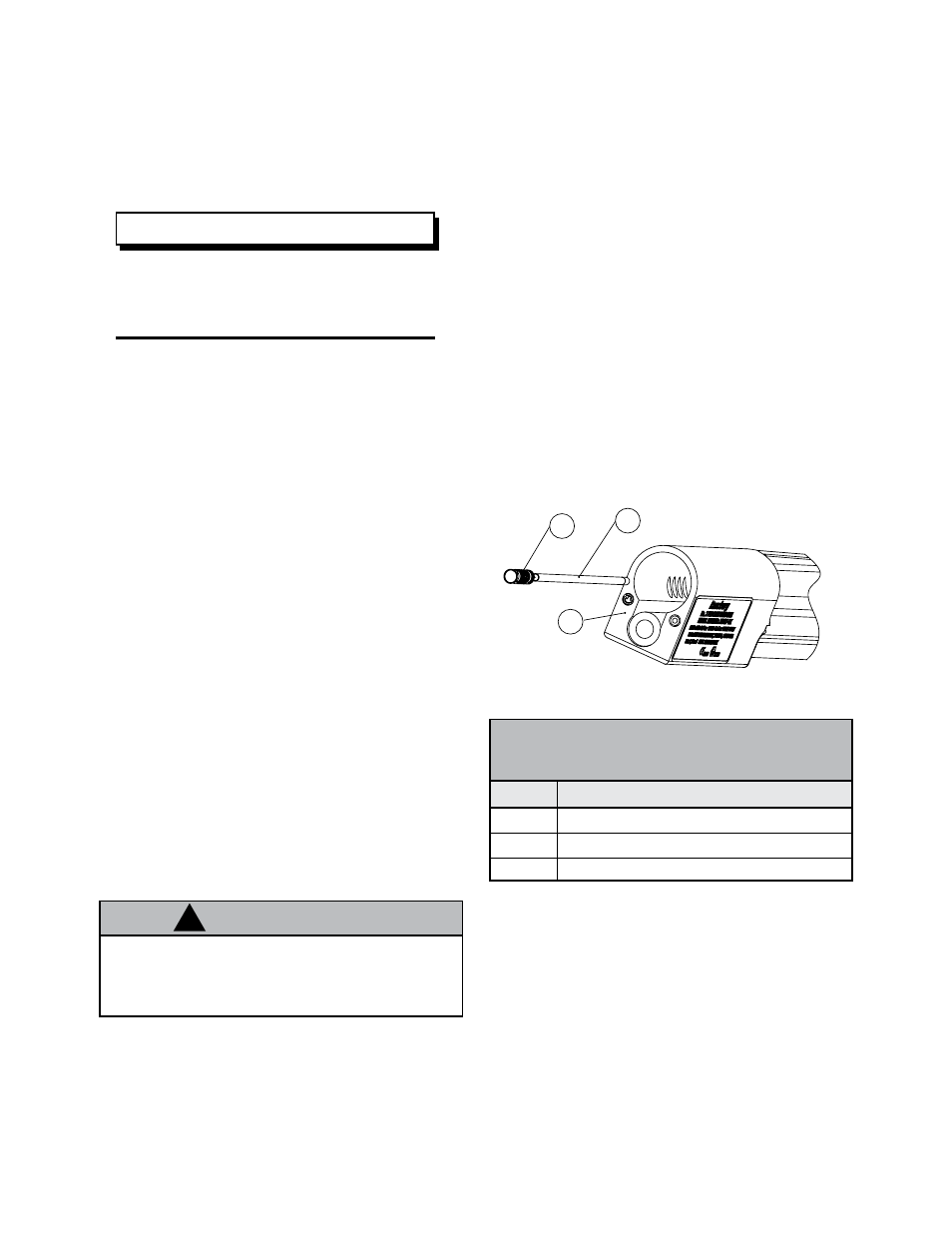

Ground Resistor Replacement

(Refer to Figure 23)

1. Remove the cable/motor assembly per steps

1 and 2 of “Cable Assembly Replacement” in the

“Maintenance” section.

Figure 23: Ground Resistor Removal

2. Tilt the Barrel (Item 3) so the rear opening is

down. The resistor (Item 1) and the spring (Item

2) should fall out of the drive shaft.

3. Measure the resistance of the resistor (Item 2)

using a MegOhm meter with leads placed end to

end. The resistance should be between 11,000 to

9,000 MW. If the resistor is outside of this range,

it must be replaced, or there is a large hole in the

center of the spray pattern.

C A U T I O N

!

NOTE

Item #

1

2

3

GROUND RESISTOR REMOVAL

(Figure 23)

Description

Spring

Ground Resistor 10,000 MΩ

Barrel

5. Measure the resistance of the resistor (Item 2)

4 using a MegOhm meter with leads placed end

to end. The resistance should be between 550

to 500 MΩ. If the resistor is outside of this range,

it must be replaced.

6. Fill the inside diameter of a new resistor (Item

4) with dielectric grease. Hold the nozzle of the

grease tube to the hole on one end of the resistor

and slowly squeeze the grease into the resistor

until it protrudes from the opposite end of resistor.

Coat the outside surface of the resistor lightly with

the dielectric grease .

7. Insert the resistor (Item 4) into the front of the

resistor housing (Item 5) with the inked end (black)

of the resistor toward the front of the barrel (Item 6).

8. At the front end of the barrel (Item 6) use a

screwdriver to hold the resistor (Item 4). At the

back of the barrel insert the washer (Item 7) and

screw (Item 8) into the resistor housing (Item 5).

With a long screwdriver screw the screw into the

resistor.

3

2

1