No. 2 handgun brush positioning and wear, Ransburg – Ransburg No. 2 Process Handgun Electric Motor User Manual

Page 18

No. 2 Process Electric Motor Version - Installation

Ransburg

14

AH-13-01.1

NO. 2 HANDGUN BRUSH

POSITIONING AND WEAR

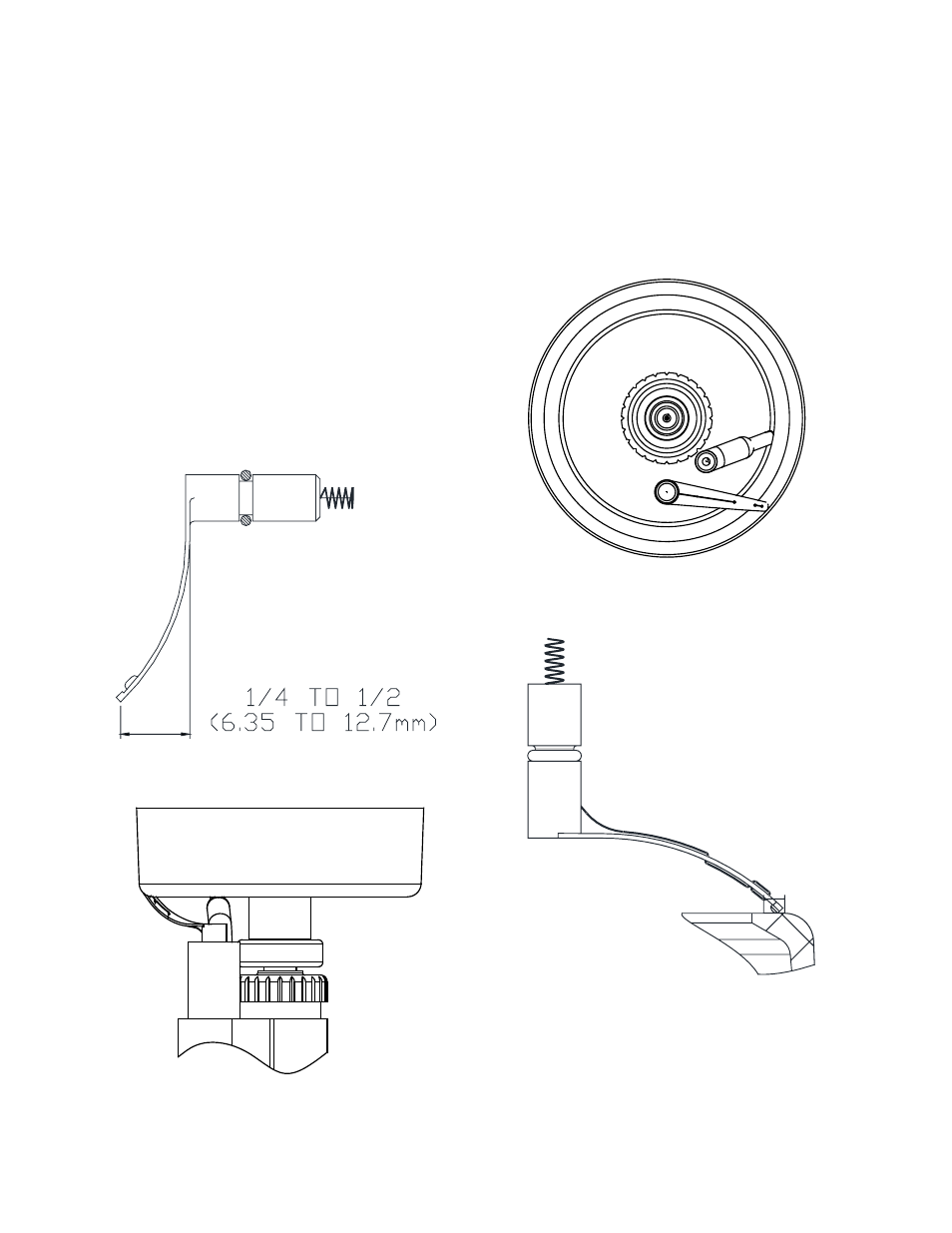

(Refer to Figure 9)

When installing the electrical contact brush (3695-

00), it is important that it is properly positioned to

provide LIGHT CONTACT with the bell conductive

coating. Excessive contact pressure from the con-

tact brush will wear away the conductive coating

or the brush tip, causing poor electrical contact.

The small plastic pad at the tip of the brush arm

should lightly contact the black bell coating, not the

wire. The wire should never contact the coating.

The tip of the brush should not extend past the

edge of the bell cup or into the radius at the edge

(see Figure 9).

Figure 9-1: Un-Installed Brush Shape

Figure 9-2: Brush Contact Position

The brush should normally have a slight curve to

the arm. The more pressure applied the lesser

the curve (see Figure 4). The tip of the brush

assembly must be inspected prior to each use

for wear. When one-half (1/2) of the plastic tip

is worn away the brush assembly should be re-

placed (see Figure 10).

Figure 9-3: Brush and Feed Tube Positioning

Figure 9-4: Brush Contact Area